Mechanical stream-handing gasification furnace and used raw material

A gasification furnace and mechanical technology, applied in the field of mechanical continuous feeding gasification furnace and the raw materials used, can solve the problems of immaturity, etc., and achieve the effects of low cost, large economic and environmental benefits, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

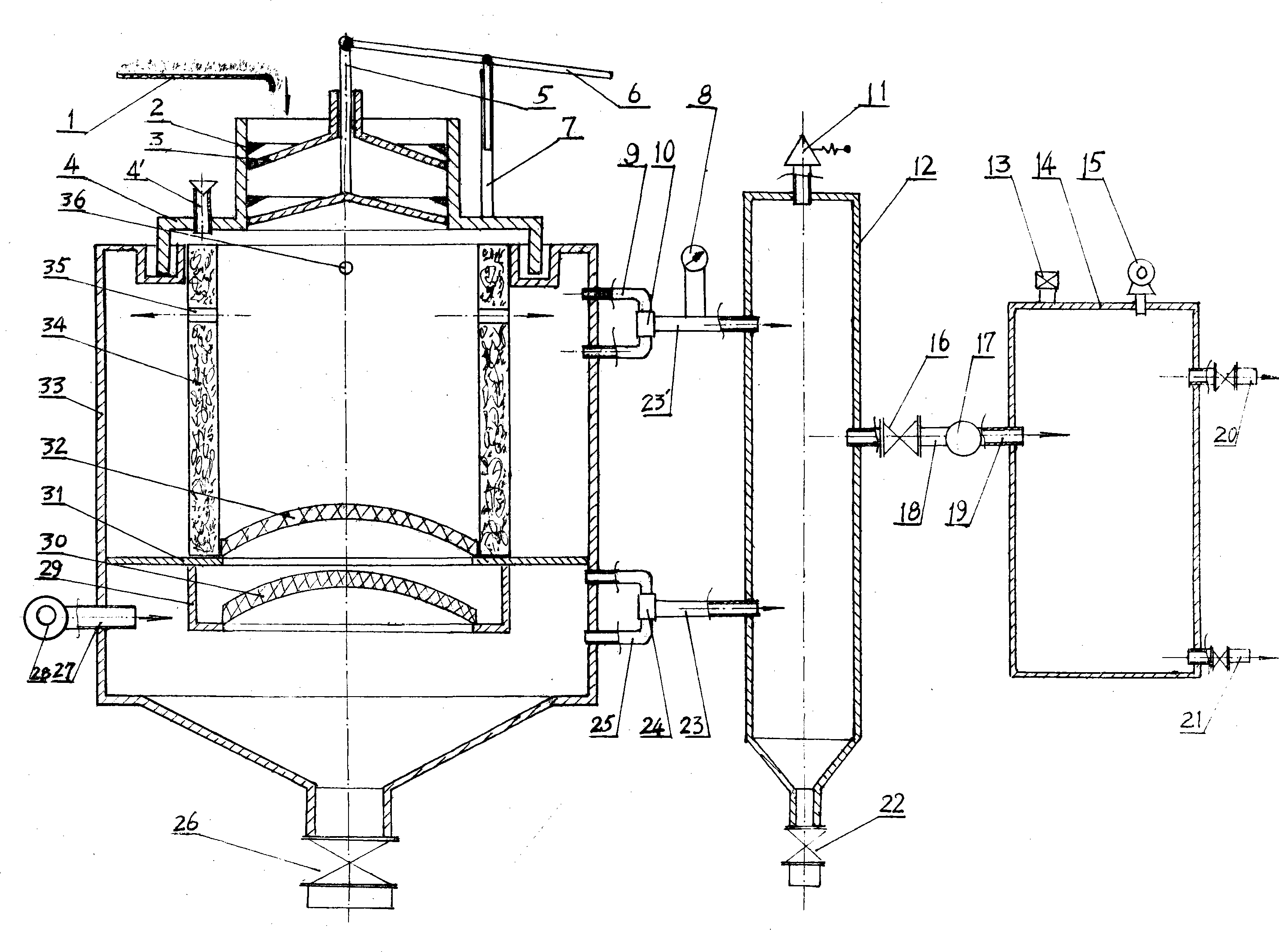

[0019] With (weight %) humic acid soil=81, industrial salt=5, 4 parts of limestone+1 part of active carbon mixture=9 of 10 orders, water=5, the sum of each component content is 100%, mixing and pressing into particle size is 30mm spherical raw material, gas production, the effect is better, the gasification furnace used is shown in the attached figure.

Embodiment 2

[0021] With (weight %) mixed interbed coal=80, industrial salt=2, 4 parts of limestone+1 part of active carbon mixture=8 of 15 meshes, water=10, the sum of each component content is 100%, mixing and pressing granulation The grade is 40mm spherical raw material, which produces gas and has good effect. The gasifier used is shown in the attached figure.

Embodiment 3

[0023] Use (weight %) to wash coal gangue=89, industrial salt=1, 4 parts of limestone+1 part of active carbon mixture=4 of 20 orders, water=6, the sum of each component content is 100%, mixing and pressing granulation is extremely 50mm spherical Raw material, gas production, good effect, the gasification furnace used is shown in the accompanying drawing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com