Flameless solid fuel, and preparation method and application thereof

A solid fuel and fuel technology, applied in solid fuel, fuel, biofuel, etc., can solve the problems of short storage period, short duration, and low combustion calorific value, and achieve high internal pressure, long duration, and high combustion heat high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

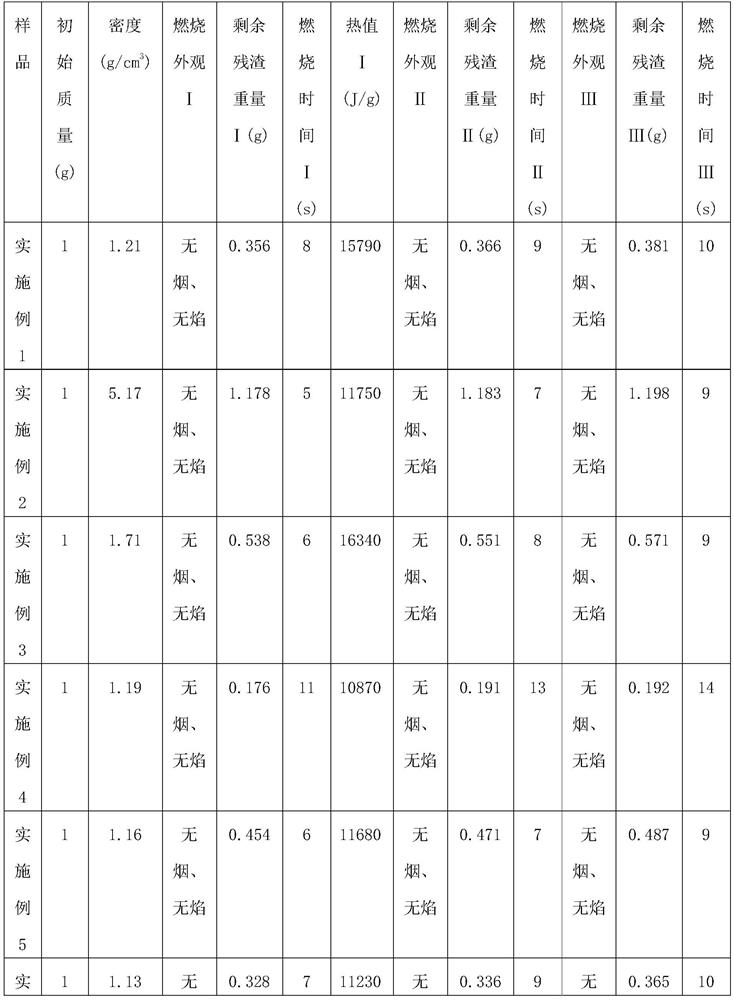

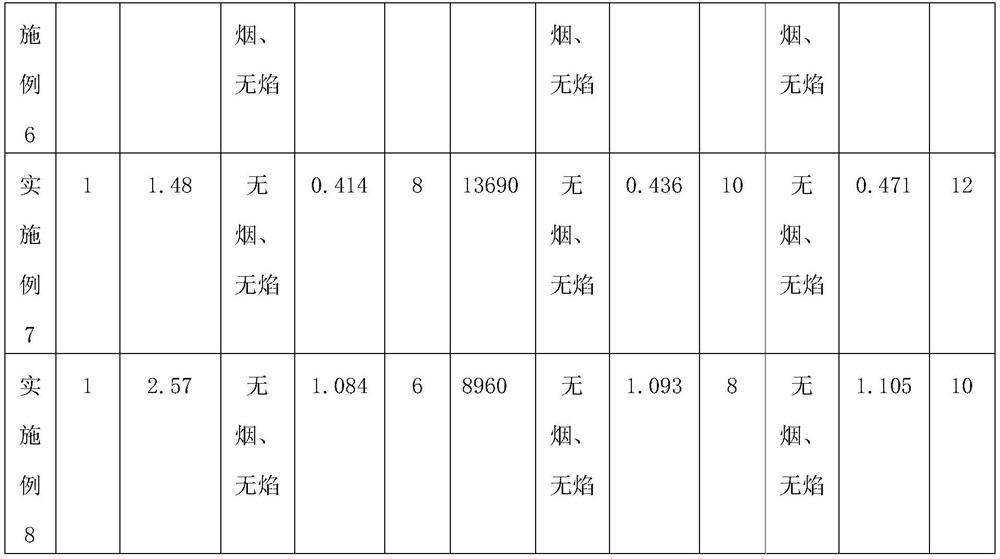

Examples

Embodiment 1

[0062] Under normal temperature conditions, add 60 grams of vegetable oil methyl ester, 25 grams of calcium peroxide, 5 grams of potassium sorbate, and 10 grams of PU-201 into a 500 ml three-neck round bottom flask with stirring and vacuuming functions, and stir for 5 Minutes, after the materials in the bottle are fully mixed evenly, slowly turn on the vacuum, remove the air bubbles contained in the materials as much as possible, then turn off the stirring, replenish the air to normal pressure, pour the materials in the bottle into the mold, and place it at room temperature for 30 minutes. The surface has been cured and shaped to obtain an environmentally friendly solid fuel.

Embodiment 2

[0064] Under normal temperature conditions, add 30 grams of aluminum powder, 30 grams of calcium peroxide, 5 grams of potassium sorbate, and 35 grams of PU-201 into a 500 ml three-neck round bottom flask with stirring and vacuuming functions, and stir for 5 minutes , After the materials in the bottle are fully mixed, slowly turn on the vacuum, remove the air bubbles contained in the materials as much as possible, then turn off the stirring, replenish the air to normal pressure, pour the materials in the bottle into the mold, and leave it at room temperature for 30 minutes. It has been solidified and formed to obtain an environmentally friendly solid fuel.

Embodiment 3

[0066] Under normal temperature conditions, add 55 grams of anthracite coal powder, 20 grams of calcium peroxide, 5 grams of potassium sorbate, and 20 grams of PU-201 into a 500 ml three-neck round bottom flask with stirring and vacuuming functions, and stir for 10 minutes , After the materials in the bottle are fully mixed, slowly turn on the vacuum, remove the air bubbles contained in the materials as much as possible, then turn off the stirring, replenish the air to normal pressure, pour the materials in the bottle into the mold, and leave it at room temperature for 30 minutes. It has been solidified and formed to obtain an environmentally friendly solid fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com