Carbon monoxide emission reduction sintering synergist and use method thereof

A sintering synergist, carbon monoxide technology, applied in indirect carbon dioxide emission reduction, solid fuel, petroleum industry and other directions, can solve the problems of incomplete coal combustion, waste of coal resources, incomplete combustion, etc., and improve the rate of sintering dealkalized metals , the effect of improving yield and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

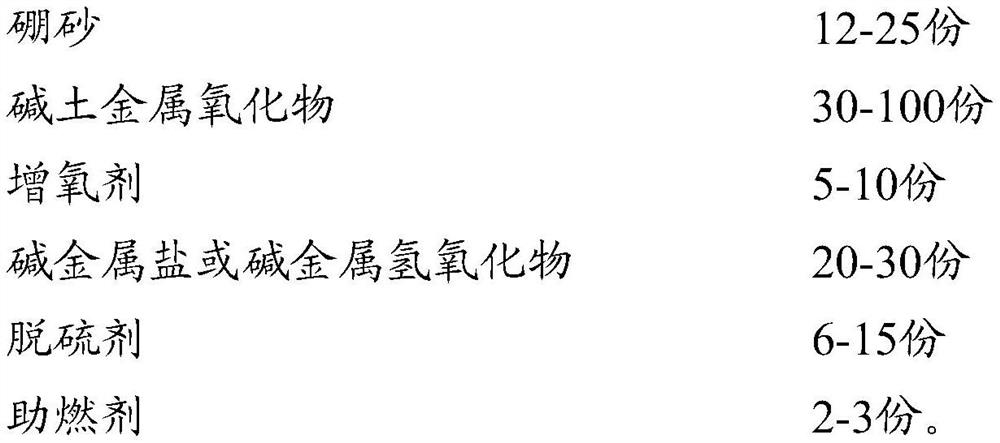

[0018] A CO emission reduction sintering synergist is prepared by mixing the following raw materials by weight:

[0019]

[0020] The combustion accelerant is composed of copper oxide, cerium oxide and aluminum oxide in a mass ratio of 1:2:3.

Embodiment 2

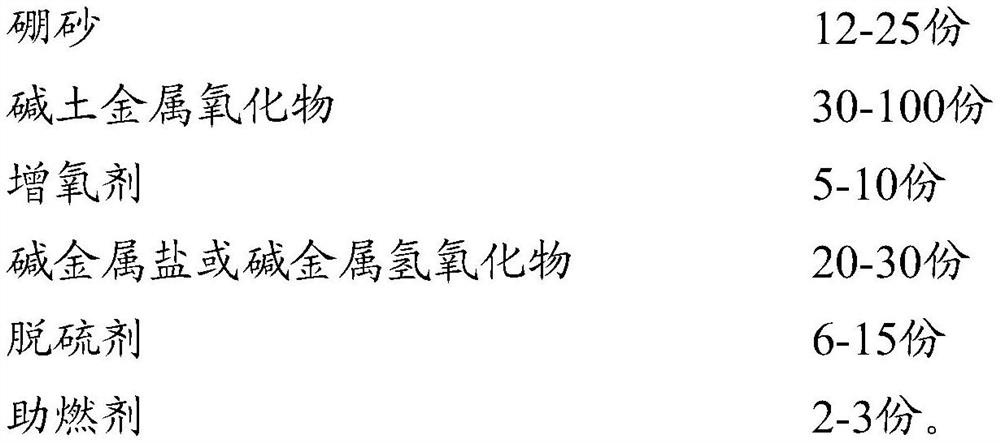

[0022] A CO emission reduction sintering synergist is prepared by mixing the following raw materials by weight:

[0023]

[0024] The combustion accelerant is composed of copper oxide, cerium oxide and aluminum oxide in a mass ratio of 1:5:3.

Embodiment 3

[0026] A CO emission reduction sintering synergist is prepared by mixing the following raw materials by weight:

[0027]

[0028]

[0029] The combustion accelerant is composed of copper oxide, cerium oxide and aluminum oxide in a mass ratio of 1:1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com