Split-flow recompression pure oxygen combustion circulation system

A circulating system and recompression technology, applied in combustion engines, internal combustion piston engines, steam engines, etc., can solve the problems of system efficiency, large heat loss, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

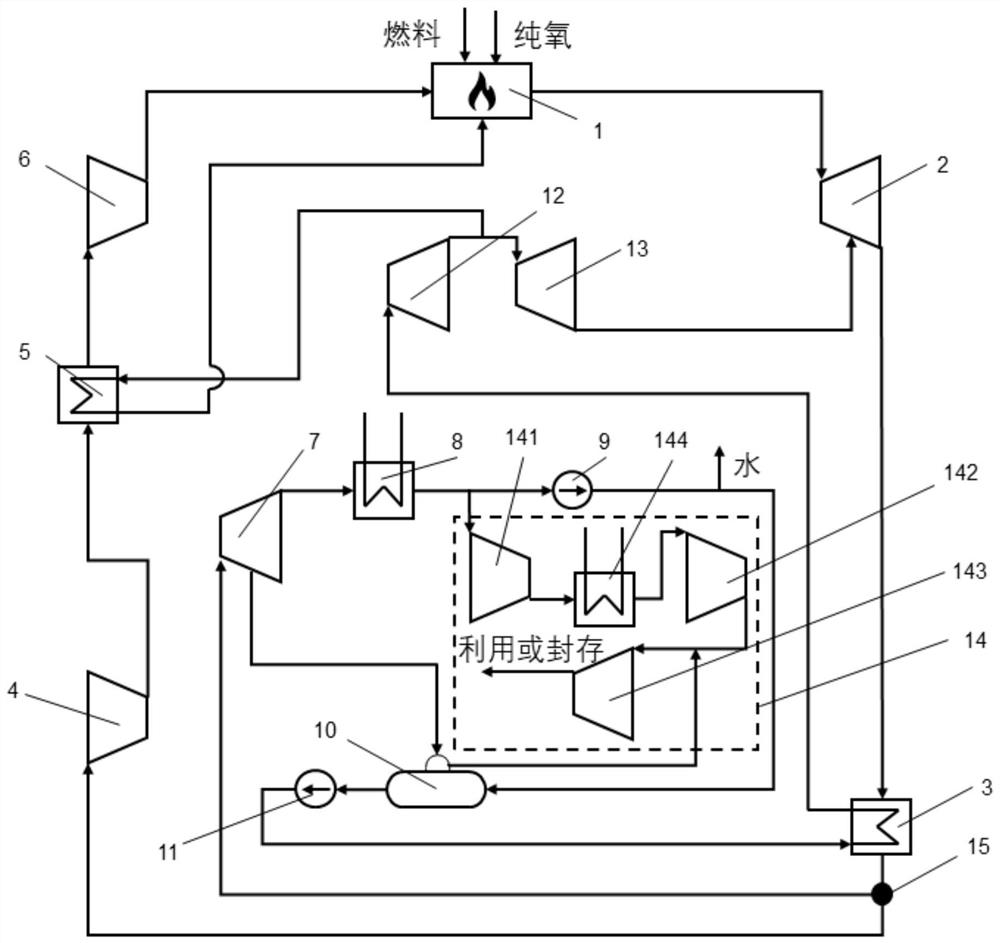

[0056] The split flow recompression pure oxygen combustion cycle system of this embodiment can be applied to the case where the fuel is hydrocarbon. Such as figure 1As shown, the combustion chamber 1, the gas turbine 2, the waste heat boiler 3, the splitter device 15, the first low-pressure compressor 4 and the first high-pressure compressor 6 are sequentially connected in series to form a flow path for the circulation of the working medium, and the flow path can be In a semi-closed circuit, the low-pressure steam turbine 7, condenser 8, condensate pump 9, deaerator 10 and feed water pump 11 are sequentially connected in series to form a flow path for gas-liquid separation.

[0057] Specifically, the outlet side of the combustion chamber 1 is connected to the high-temperature inlet side of the gas turbine 2 , the low-temperature outlet side of the gas turbine 2 is connected to the hot-end inlet side of the waste heat boiler 3 , and the hot-end outlet side of the waste heat boi...

no. 2 approach

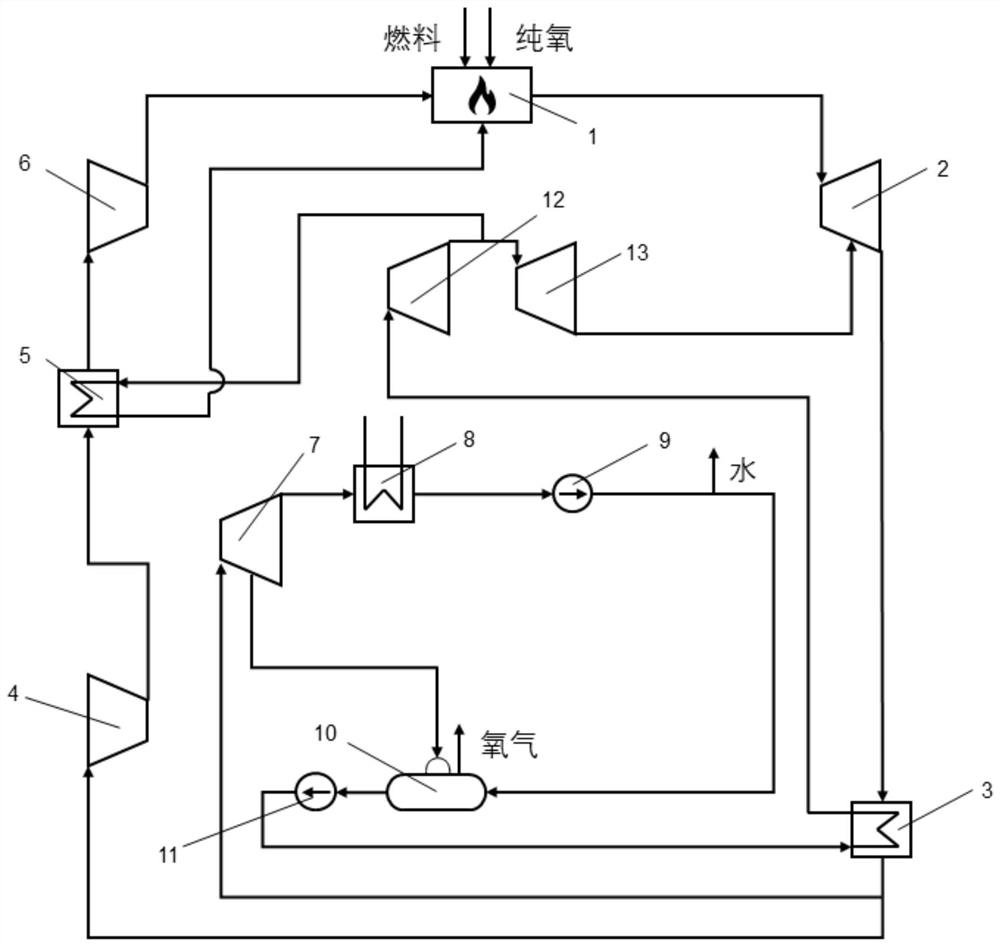

[0079] figure 2 A split-flow recompression oxy-combustion cycle system according to a second embodiment of the present application is shown. The same or similar reference numerals are assigned to the same or similar components as those of the first embodiment, and detailed descriptions of these components are omitted.

[0080] The split flow recompression pure oxygen combustion cycle system of this embodiment can be applied to the case where the fuel is hydrogen. Such as figure 2 As shown, the difference with the first embodiment is: (1) Since the combustion product of hydrogen and oxygen is water vapor, not doped with carbon dioxide, the circulation system of this embodiment does not include a carbon dioxide capture system 14; (2 ) Since there is no need to adjust the working medium ratio of each branch according to the hydrocarbon ratio of the hydrocarbon, the flow splitting device 15 equipped with a proportional regulating valve is not provided, as long as the gas working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com