A kind of environment-friendly fireproof coating and preparation method thereof

A fire retardant coating and environmental protection technology, applied in the field of coatings, can solve the problems of environmental pollution and deterioration of the physical properties of the coated object, and achieve the effects of simple production method, convenient production and less equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

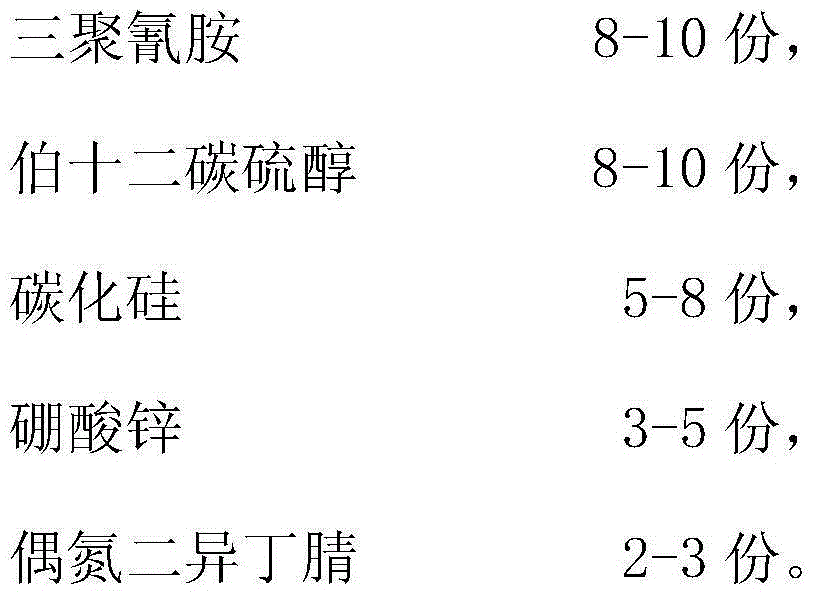

Embodiment 1

[0018] (1) Stir 30kg of cellulose acetate, 10kg of ammonium polyphosphate, 10kg of melamine, 5kg of silicon carbide, 3kg of zinc borate and 2kg of azobisisobutyronitrile at 50°C for 1 hour,

[0019] (2) Place the product of step (1) in a nitrogen atmosphere, under airtight conditions, under a pressure of 2 MPa, stir for 50 minutes at 40° C., add 8 kg of primary dodecyl mercaptan, and stir evenly to obtain an environmentally friendly fireproof coating.

[0020] The paint forms a 2mm coating on the steel structure material, and its fire resistance is determined to be 98 minutes.

Embodiment 2

[0022] (1) 40kg of cellulose acetate, 15kg of ammonium polyphosphate, 8kg of melamine, 8kg of silicon carbide, 5kg of zinc borate and 3kg of azobisisobutyronitrile were stirred for 2 hours at 80°C,

[0023] (2) Place the product of step (1) in a nitrogen atmosphere, under airtight conditions, under a pressure of 2 MPa, and stir at 45°C for 30 minutes, add 10 kg of primary dodecyl mercaptan and 2 kg of iron oxide red, and stir evenly to obtain an environmentally friendly fireproof coating.

[0024] The paint forms a 2mm coating on the steel structure material, and its fire resistance limit is determined to be 95 minutes.

Embodiment 3

[0026] (1) 305kg of cellulose acetate, 13kg of ammonium polyphosphate, 10kg of melamine, 7kg of silicon carbide, 5kg of zinc borate and 3kg of azobisisobutyronitrile were stirred for 2 hours at 60°C,

[0027] (2) Place the product of step (1) in a nitrogen atmosphere, under airtight conditions, under a pressure of 3 MPa, stir for 40 minutes at 50° C., add 10 kg of primary dodecyl mercaptan, and stir evenly to obtain an environmentally friendly fireproof coating.

[0028] The paint forms a 2mm coating on the steel structure material, and its fire resistance is determined to be 94 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com