Protective film for corrosion resistance of metal niobium at high temperature and preparation method of protective film

A technology of protective film and metal niobium, which is applied in the direction of metal material coating technology, climate sustainability, and reduction of greenhouse gases, and can solve problems such as corrosion of refractory metal niobium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention is a method for preparing a protective film based on the corrosion resistance of metal niobium at high temperature. The refractory metal niobium is placed in liquid lead-bismuth to form a protective film in situ, and the specific steps are as follows:

[0057] S1. Obtain dense niobium rods through vacuum smelting, rolling, and annealing, and then cut the niobium rods into several experimental samples of 50x6x3mm; grind the experimental samples with a grinder and ultrasonic cleaning with alcohol to remove the wire cutting marks of the samples and oil pollution;

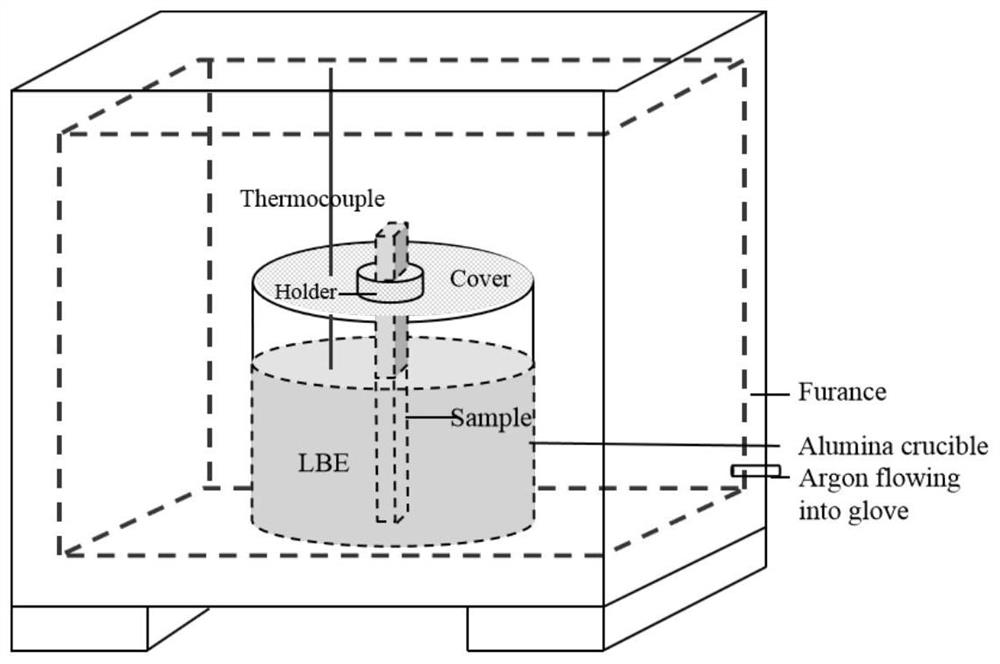

[0058] S2. Put 500g of lead-bismuth alloy (Pb44.5%, Bi55.5%) for nuclear use into a 50ml alumina crucible, and put them together into a high-temperature energy-saving atmosphere furnace; set the program to raise the temperature in the furnace to 125-200°C , keep warm for 30-60 minutes to completely melt the lead-bismuth alloy;

[0059] The so-called mass process of the lead-bismuth alloy i...

Embodiment 1

[0086] Experimental preparation process of refractory metal Nb in situ forming protective film in liquid lead bismuth:

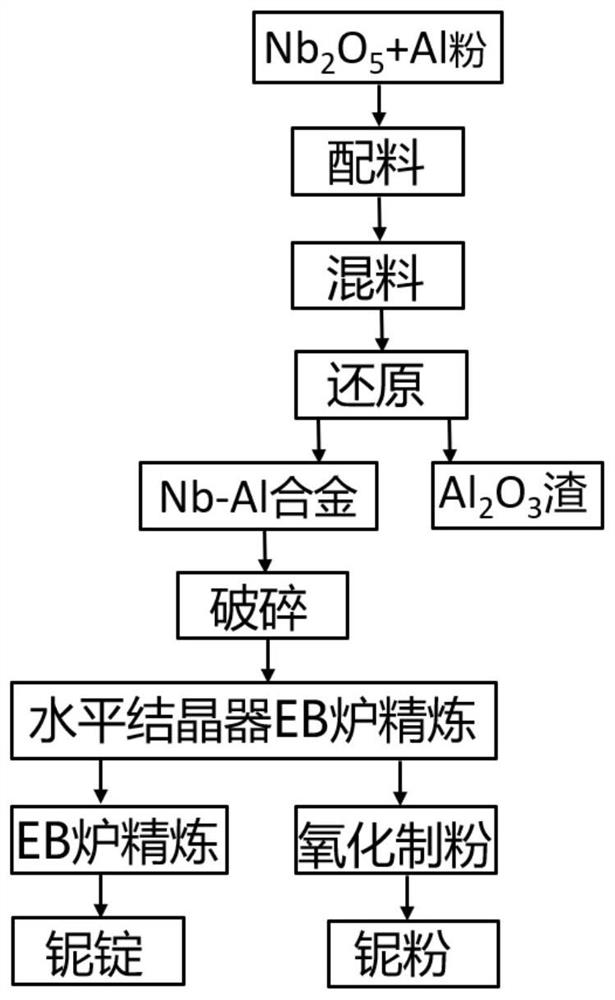

[0087]The production process of the refractory metal niobium used in this example: aluminothermic reduction of Nb 2 o 5 → Crude niobium → Purification by electron beam melting → Rolling → Annealing.

[0088] Among them, the thermite reduction of Nb 2 o 5 The flow chart is as figure 1 , the reaction formula is:

[0089] 3Nb 2 o 5 +10Al→6Nb+5Al 2 o 3

[0090] The impurity concentration of the finally prepared Nb is shown in Table 1. The lead-bismuth alloy used in the experiment was provided by Henan Huapu Alloy Materials Co., Ltd., China, and the impurity concentration was detected by SEM-EDS, as shown in Table 2.

[0091] 1) The diameter is obtained by smelting, rolling, heat treatment, etc. It is a 20mm dense niobium bar, and the bar is cut into 50x6x3mm experimental samples, lightly polished with 1000#, 1200#, 1500# SiC water sandpaper, and pol...

Embodiment 2

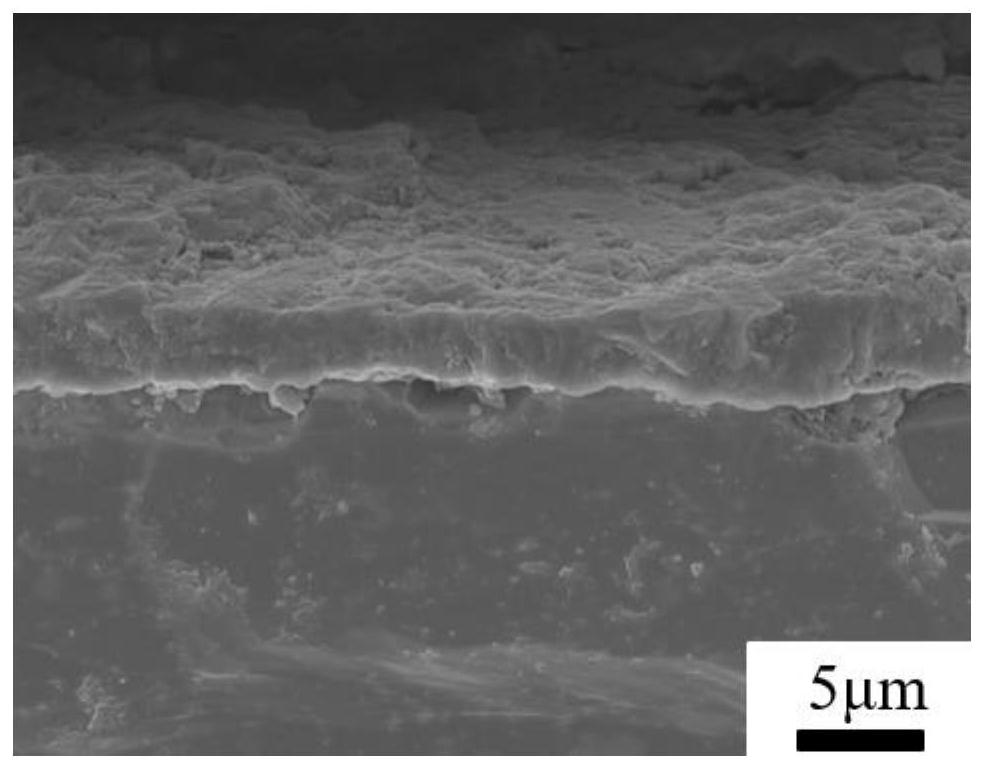

[0095] According to the aforementioned plan, the sample is taken out within the interval of 20-40h, and the cross-section of the sample in the interval of 20-40h is obtained by preparing the cross-sectional sample, such as Figure 4 As shown, the in situ generated NbO / NbO can be observed 2 The thickness of the protective film is 4-5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com