Photovoltaic welding strip and preparation method thereof

A photovoltaic ribbon and solder joint technology, applied in the field of solar cells, can solve the problems of poor corrosion resistance of copper materials, affecting electrical conductivity and reliability, etc., and achieve the effects of ensuring electrical conductivity, improving oxidation resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

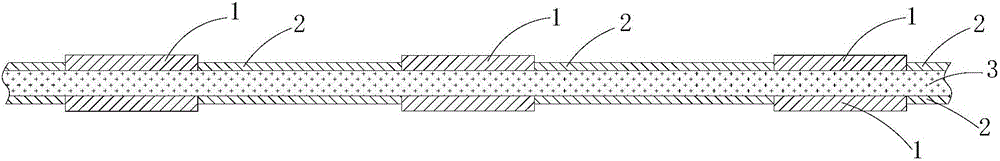

[0030] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. The definition of orientation in the present invention is based on the usual viewing angle of view of those skilled in the art and is defined for the convenience of description, and does not limit the specific direction. For example, the above corresponds to the attached figure 1 The upper side of the paper surface, the lower corresponds to the attached figure 1 The lower side of the middle paper.

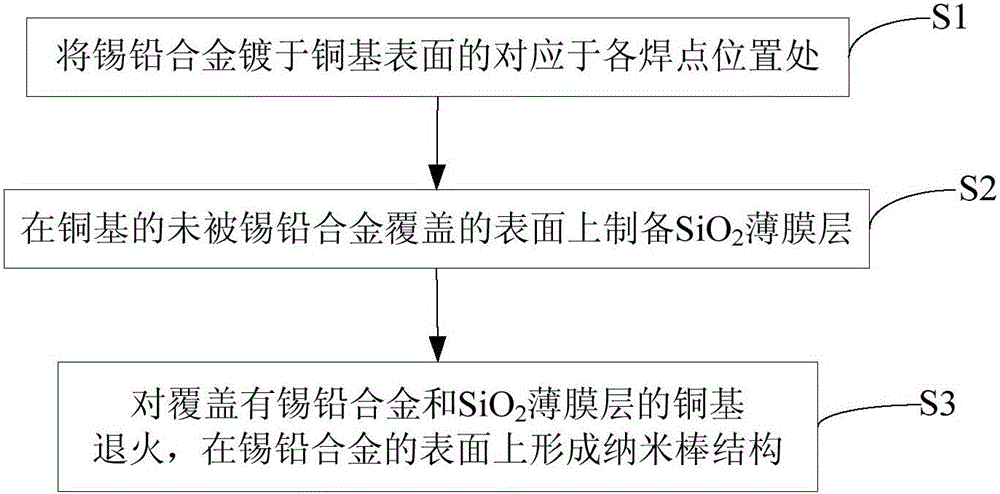

[0031] See attached figure 1 As shown, a photovoltaic ribbon, including a copper base 3, a plurality of welding metal parts 1 and SiO 2 Thin film layer 2. Among them, the copper base 3 uses pure copper with a purity greater than 99.99% as the base material of the photovoltaic ribbon. The copper base 3 has a front side and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com