Method for restraining rotational flow of roughing slag in steel ladle during steel releasing of steel ladle

A ladle and suppressor technology, applied in the field of metallurgical smelting and rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

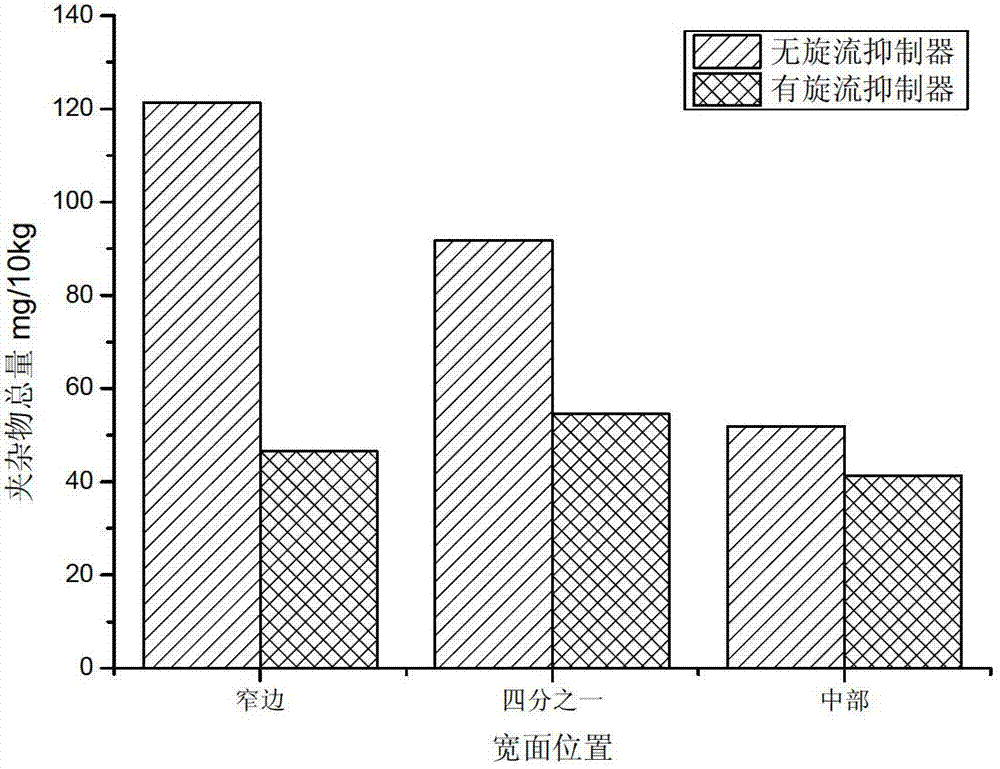

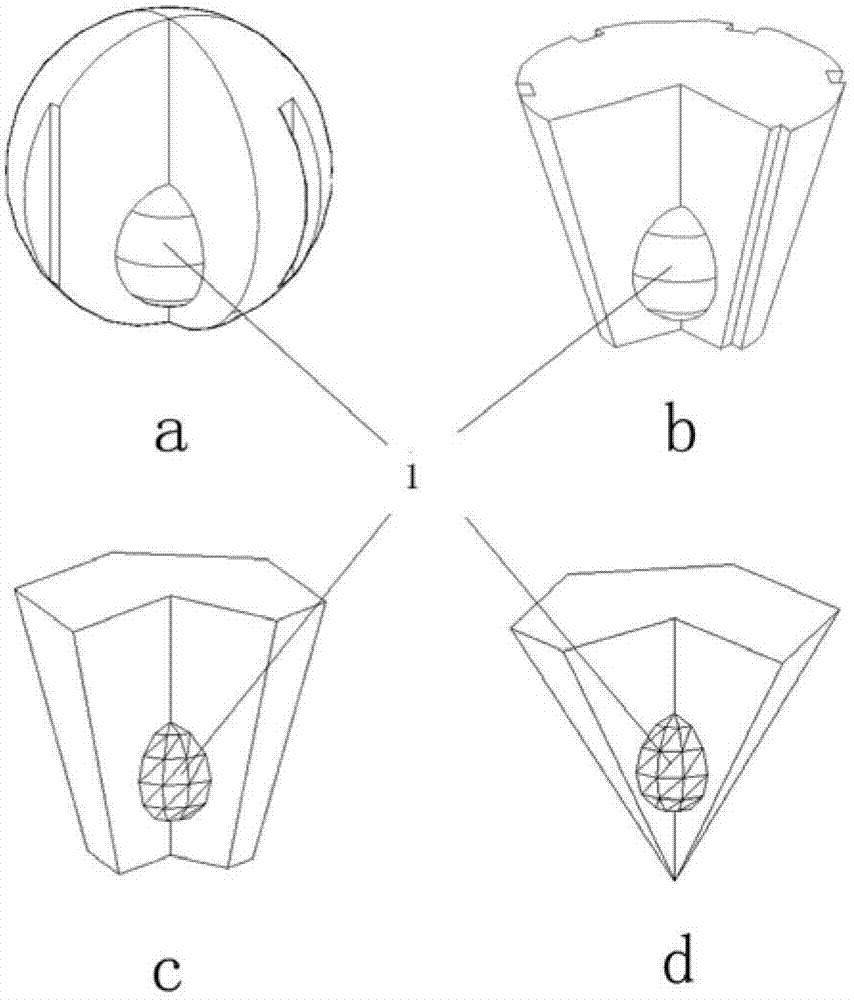

[0040] In the actual production process, it is inevitable to generate swirling flow in the ladle, and it is often accompanied by serious slag entrainment, which will seriously damage the interior of the continuous casting slab. In this implementation step, the hexagonal pyramid-shaped swirl suppressor is used as the implementation body to participate in the calculation, and the design and calculation of the spherical swirl suppressor is the same as that of the vertebral body.

[0041] The specific implementation steps of the present invention are as follows:

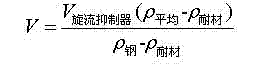

[0042] Measure the density of the mold slag and molten steel contained in the ladle where the swirl suppressor will be used, and determine the density range of the swirl suppressor. Make its density between the density of molten steel ρ 钢 and mold flux density ρ 渣 Between,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com