UHPC lining structure used for tunnel and construction method of UHPC lining structure

A tunnel and lining technology, which is applied in the UHPC lining structure for tunnels and its construction field, can solve the problems of excavation cross-sectional area, increased slag discharge, large workload, construction difficulty, and many construction procedures, etc., to improve the anchorage quality , Reduce the cross-sectional area of excavation and the amount of slag, and the effect of good support performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

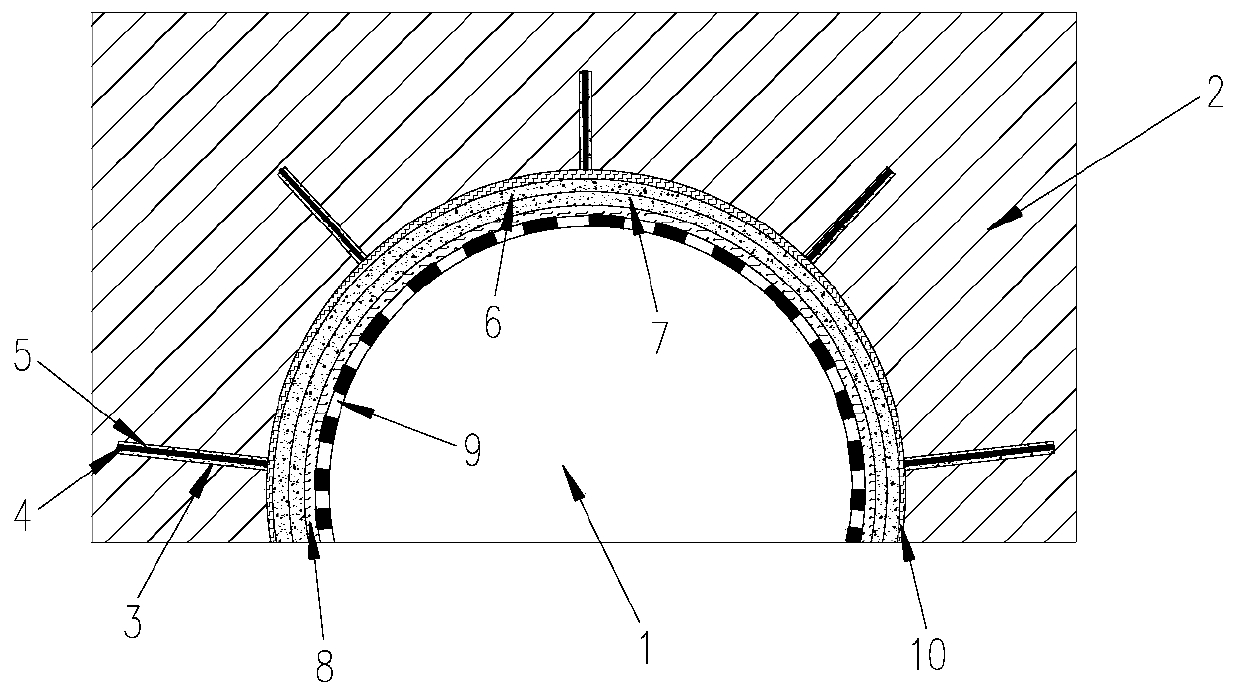

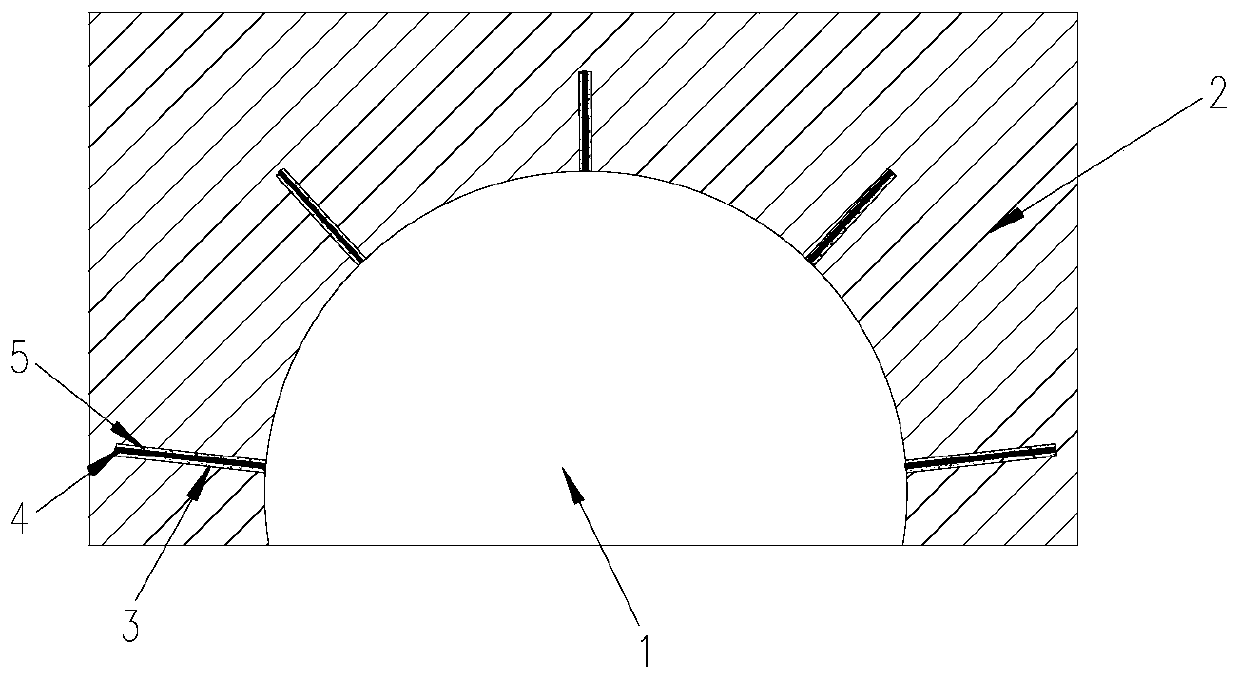

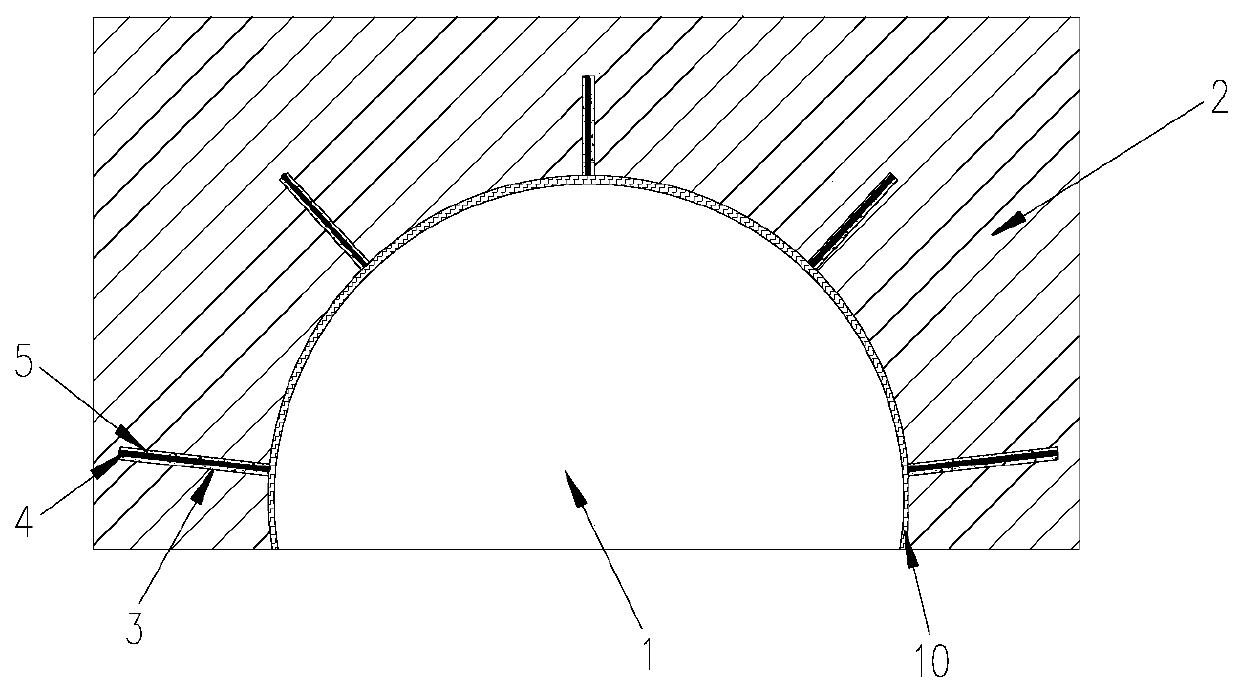

[0051] The surrounding rock level of the tunnel is Grade II, and UHPC lining structure is adopted. The lining structure is a composite lining structure composed of bolt support body and UHPC lining support layer. The bolt support includes bolt hole 3, bolt 4 and UHPC tunnel Grouting material 5, the bolt hole 3 is arranged on the surrounding rock 2 in a quincunx shape, the bolt 4 is inserted into the bolt hole 3 first, and then the bolt hole 3 is filled with UHPC channel grouting material 5; the UHPC lining supports The protective layer includes a sprayed UHPC lining layer, a decorative layer 8, a tunnel profile reflective strip 9 and a drainage blind pipe 10, the sprayed UHPC lining layer is arranged on the surface of the surrounding rock 2, the tunnel profile reflective strip 9 is fixed on the sprayed UHPC lining layer, and the decorative layer 8 Apply to the surface of the sprayed UHPC lining layer.

[0052] The sprayed UHPC lining layer is divided into a sprayed UHPC base l...

Embodiment 2

[0074] The surrounding rock of the tunnel is grade Ⅲ, and UHPC lining structure is adopted, which is a composite lining structure composed of bolt support body and UHPC lining support layer. The bolt support includes bolt hole 3, bolt 4 and UHPC channel grouting Material 5, the bolt hole 3 is set on the surrounding rock 2 in a quincunx shape, the bolt 4 is inserted into the bolt hole 3 first, and then the bolt hole 3 is filled with UHPC channel grouting material 5; the UHPC lining support layer Including sprayed UHPC lining layer, decorative layer 8, tunnel contour reflective strip 9 and drainage blind pipe 10, sprayed UHPC lining layer is arranged on the surface of surrounding rock 2, tunnel contour reflective strip 9 is fixed on the sprayed UHPC lining layer, and decorative layer 8 is painted Spray the surface of the UHPC lining layer.

[0075] In the present embodiment, the sprayed UHPC lining layer is divided into a sprayed UHPC base layer and a sprayed UHPC reinforced lay...

Embodiment 3

[0097] The surrounding rock level of the tunnel is grade V, and UHPC lining structure is adopted, which is a composite lining structure composed of bolt support body and UHPC lining support layer, wherein the bolt support includes bolt hole 3, bolt 4 and UHPC channel grouting Material 5, the bolt hole 3 is set on the surrounding rock 2 in a quincunx shape, the bolt 4 is inserted into the bolt hole 3 first, and then the bolt hole 3 is filled with UHPC channel grouting material 5; the UHPC lining support layer Including sprayed UHPC lining layer, decorative layer 8, tunnel contour reflective strip 9 and drainage blind pipe 10, sprayed UHPC lining layer is arranged on the surface of surrounding rock 2, tunnel contour reflective strip 9 is fixed on the sprayed UHPC lining layer, and decorative layer 8 is painted Spray the surface of the UHPC lining layer.

[0098] In this embodiment, the sprayed UHPC lining layer is divided into a sprayed UHPC base layer 6 and a sprayed UHPC reinf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com