Process for abstracting earth silicon, oxide of alumina and gallium oxide from high-alumina flying ash

A high-alumina fly ash and silica technology, which is applied in the fields of alumina/aluminum hydroxide, silica, chemical instruments and methods, etc., can solve the problems of undiscovered extraction of gallium oxide, complex production process, and high production cost. Achieve the effect of easy deep desiliconization treatment, reduce flow rate and improve extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

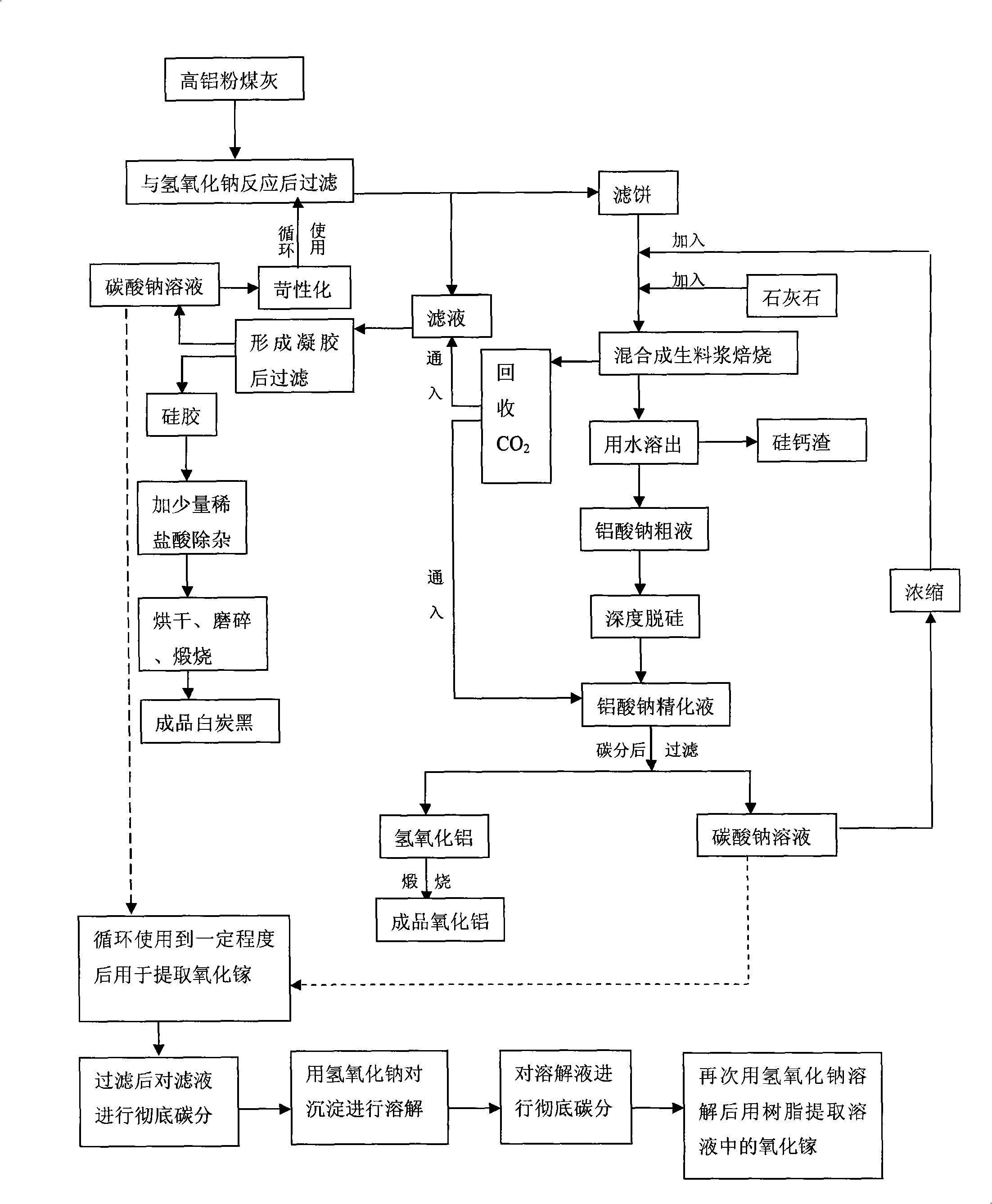

[0041] With reference to accompanying drawing, the method step when the present invention uses is:

[0042]a) Use 15% sodium hydroxide solution and high-alumina fly ash to react in a high-pressure reactor at 120°C for 3 hours and then filter. The filtrate is used as a raw material for preparing white carbon black, and the filter cake is desiliconized fly ash .

[0043] b) Feed CO into the filtrate at 70°C 2 The reaction was carried out, and when the pH value dropped to 13, the aeration was stopped. After the filtrate was left to stand for 30 minutes, the precipitate produced was removed, and CO was continuously passed through the filtrate at the same temperature. 2 until the solution is fully gelled. C) filter the mixed system of gel and solution, the sodium carbonate solution after filtering is the desilication mother liquor, according to the Na in the desilication mother liquor 2 O is added into milk of lime at a molar ratio of 1:1 and causticized at 95°C. After the NaO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com