Method for preparing ferronickel by using red mud and laterite-nickel ore

A technology of lateritic nickel ore and iron-nickel alloy, which is applied in the direction of fluidized bed furnace, etc., to achieve the effect of reducing the amount of slag, reducing the cost of reduction, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing iron-nickel alloy using red mud and laterite nickel ore, wherein the iron-nickel alloy is produced according to the following process steps:

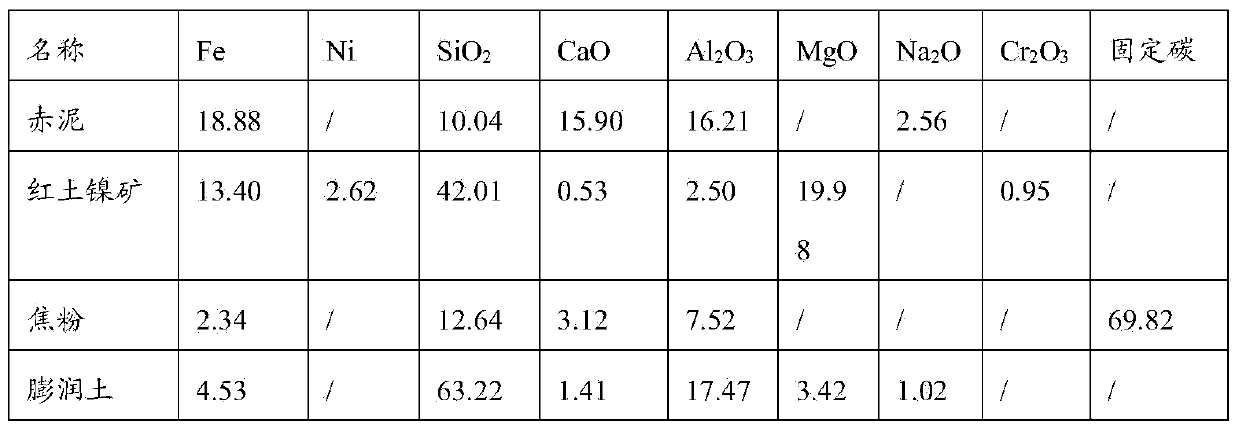

[0032] 1) The selected raw materials are red mud, laterite nickel ore and coke powder. The main chemical composition of red mud: Fe 2 O 3 32.96%, Al 2 O 3 17.25%, CaO 14.73%, SiO 2 12.81%, Na 2 O4.06%; the main chemical composition of laterite nickel ore: Fe 16.62%, Ni 1.70%, MgO 17.18%, CaO 0.31%, SiO 2 40.12%, Cr 2 O 3 0.86%; the coke powder contains more than 85% of fixed carbon, ash content is less than 12.5%, sulfur content is less than 0.6%; the main chemical composition of bentonite is: SiO 2 67%, Al 2 O 3 13%, Fe 2 O 3 3%, Na 2 O4%, CaO3%.

[0033] 2) According to the mass ratio of (red mud: laterite nickel ore: coke powder: bentonite)=(100:60:10:3.4), weigh 10kg red mud, 6kg laterite nickel ore, and 1.0kg coke powder , 0.34kg of bentonite is mixed uniformly, and an appropriate amount of water is added, ...

Embodiment 2

[0036] A method for preparing iron-nickel alloy using red mud and laterite nickel ore, wherein the iron-nickel alloy is produced according to the following process steps:

[0037] 1) The selected raw materials are red mud, laterite nickel ore, coke powder, bentonite and polyvinyl alcohol. The composition of red mud, laterite nickel ore coke powder and bentonite is the same as that of Example 1;

[0038] 2) According to the mass ratio of (red mud: laterite nickel ore: coke powder: bentonite: polyvinyl alcohol) = (100:100:12:3:1), weigh the red mud and laterite nickel ore 10kg each, 1.2kg coke powder, 0.3kg bentonite, and 0.1kg polyvinyl alcohol are uniformly mixed, and an appropriate amount of water is added. The pellets are made into agglomerates with a ball press and dried naturally in flowing air.

[0039] 3) The dry agglomerates prepared by the above steps are sent to a 150kW submerged arc furnace for direct reduction smelting, the reduction temperature is raised to 1550°C, and t...

Embodiment 3

[0041] A method for preparing iron-nickel alloy using red mud and laterite nickel ore, wherein the iron-nickel alloy is produced according to the following process steps:

[0042] 1) The selected raw materials are red mud, laterite nickel ore, coke powder, and paper pulp waste liquid, and the composition of each raw material is the same as in Example 1.

[0043] 2) According to the mass ratio of (red mud: laterite nickel ore: coke powder: pulp waste liquid) = (10: 100: 7.3: 1.3), weigh the red mud 1kg, laterite nickel ore 10kg, coke Mix 0.73kg of powder and 0.13kg of paper pulp waste liquid, add appropriate amount of water, and form agglomerates with a ball press and dry naturally in flowing air.

[0044] 3) The dry agglomerates prepared by the above steps are sent to a 150kW submerged arc furnace for direct reduction smelting, the reduction temperature is raised to 1550°C, and the temperature is kept for 5-10 minutes, and then the iron-nickel alloy is obtained after removing the sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com