Pre- desiliconizing method from fly ash or slag

A pre-desilication and fly ash technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as high energy consumption, high requirements for desiliconization equipment, and low pre-desilication rate , to reduce the roasting temperature, alleviate the contradiction between supply and demand, and improve the reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order for those skilled in the art to further understand the features and technical contents of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. The accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention.

[0032] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

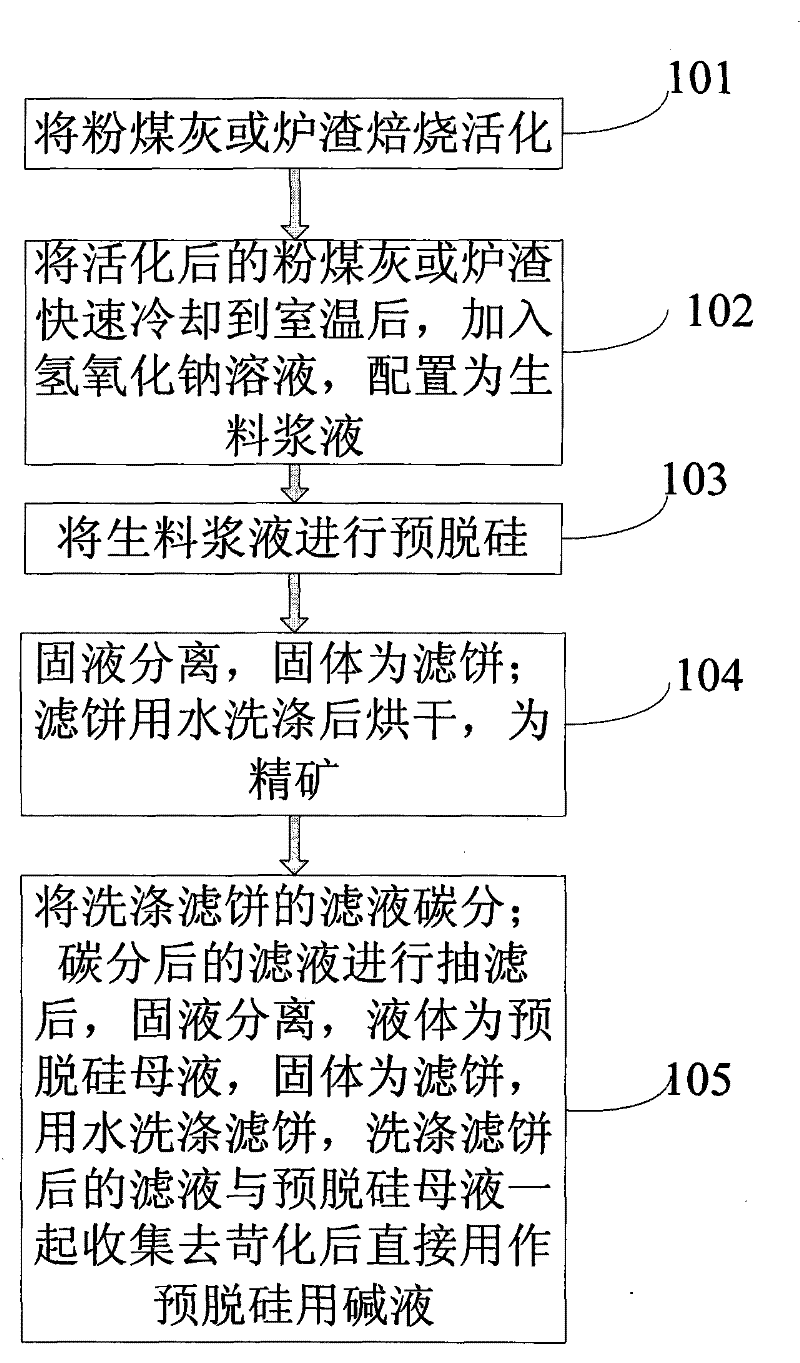

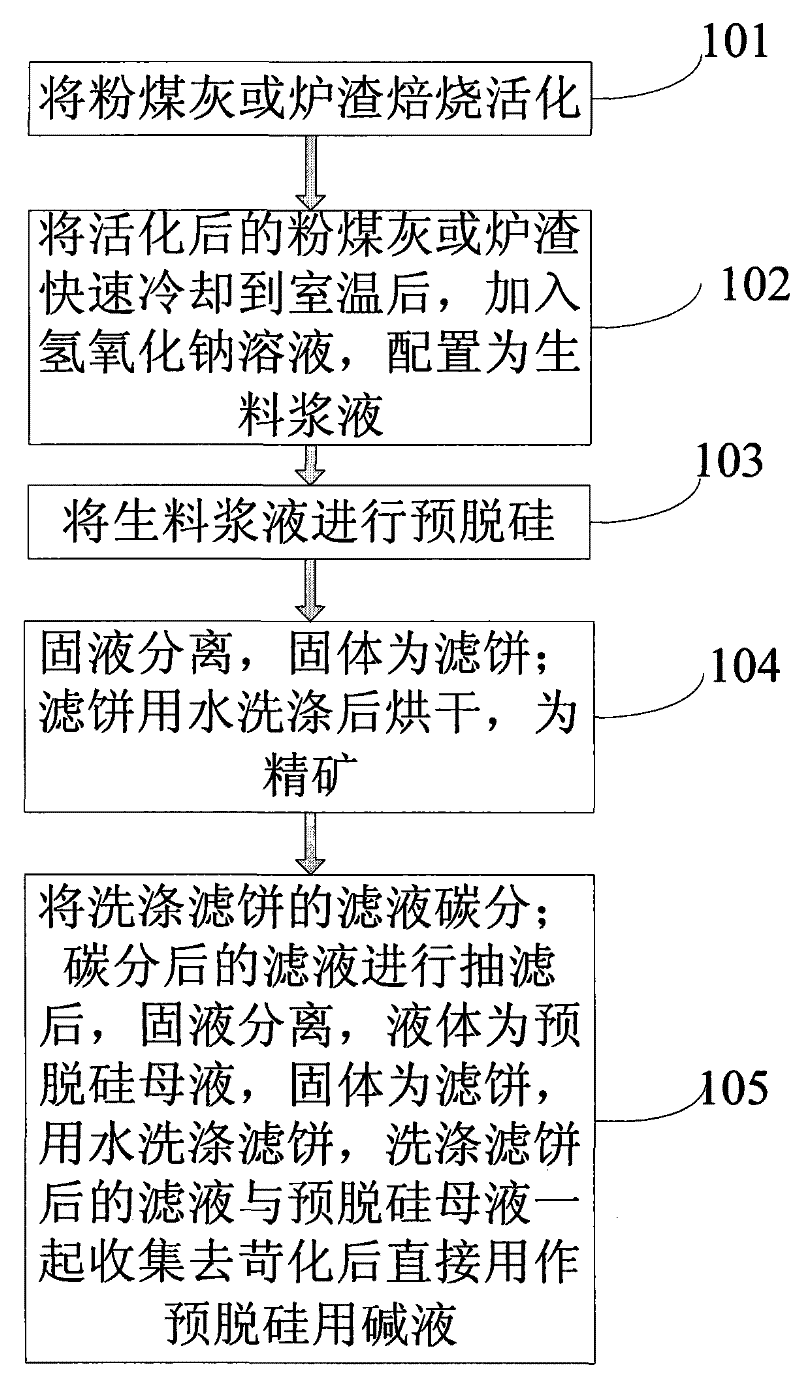

[0033] Such as figure 1 As shown, the method for pre-desilication of fly ash or slag can be realized through the following steps:

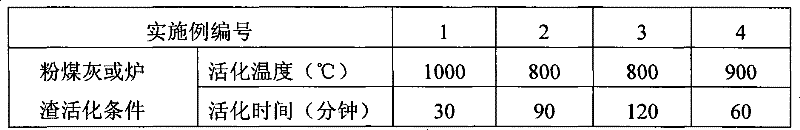

[0034] 101: Activate the fly ash or slag by roasting at 800°C-1000°C, and keep the temperature constant for 30-120 minutes;

[0035] 102: After rapidly cooling the activated fly ash or slag to room temperature, add sodium hydroxide solution. The concentration and amount of sodium hydroxide solution added are: the concentration is 80 g / L to 320 g / L, and every kilogram of pulve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com