Method for simultaneously extracting aluminum oxide from two aluminum-containing waste residues of fly ash and red mud

A technology of fly ash and alumina, which is applied in chemical instruments and methods, preparation of alumina/hydroxide, inorganic chemistry, etc., can solve the problems of difficulty and high cost of reuse of fly ash and red mud, and achieve improvement The effect of aluminum-silicon ratio, difficulty reduction, and high-efficiency extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

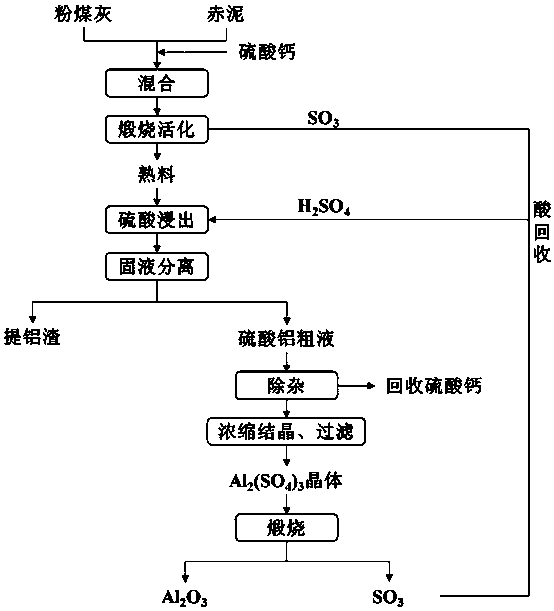

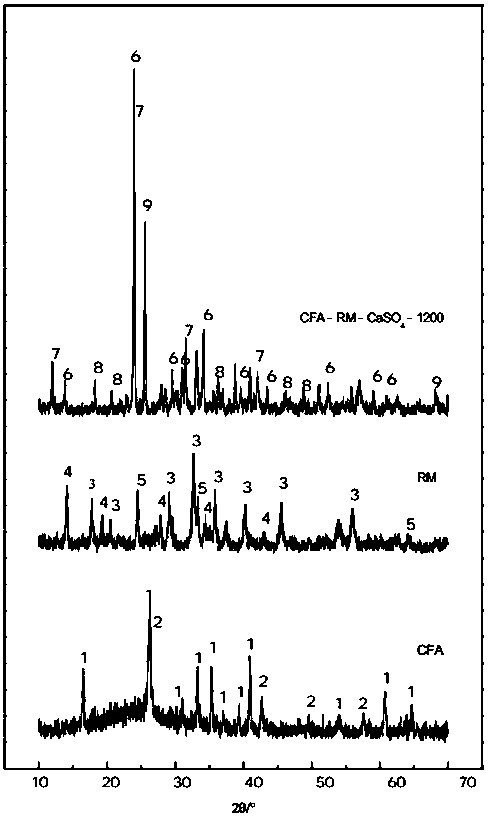

[0030] In this embodiment, the content of alumina in fly ash is 32.94%, the content of silica is 40.91%, the content of alumina in red mud is 24.20%, and the content of silica is 17.60%. The specific process is as follows:

[0031] (1) Ingredients: Mix and grind fly ash, red mud and calcium sulfate evenly in a certain proportion, so that the mass ratio of aluminum to silicon is 1:1, and the molar ratio of calcium to aluminum is 1.3:1;

[0032] (2) Calcination activation: calcining the mixed material at 1000°C for 120min;

[0033] (3) Acid leaching: Grind the calcined clinker and leaching it with 1mol / L sulfuric acid, leaching at 90°C for 30 minutes, separating solid and liquid to obtain aluminum sulfate crude liquid, and the leaching rate of alumina is 92.30%;

[0034] (4) Calcium removal: Concentrate and crystallize the filtrate to precipitate calcium sulfate crystals, and dry and recycle the precipitate after filtration;

[0035] (5) Iron removal: Add 15% hydrogen peroxide ...

Embodiment 2

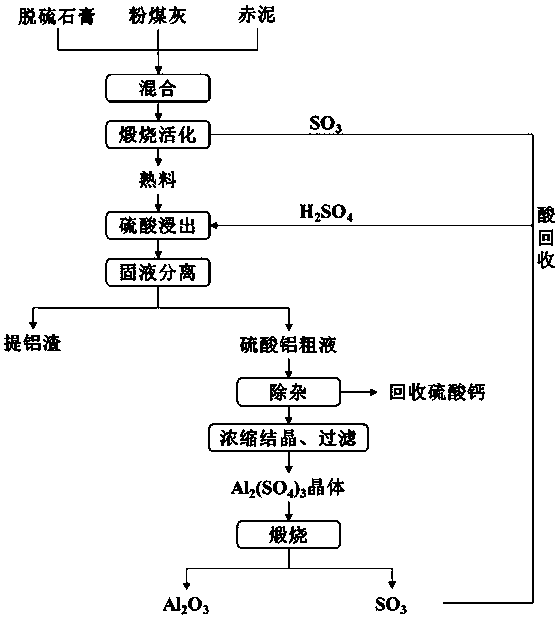

[0039] In this embodiment, the content of alumina in fly ash is 35.69%, the content of silica is 43.09%, the content of alumina in red mud is 21.26%, and the content of silica is 16.60%. The specific process is as follows:

[0040] (1) Ingredients: Mix and grind fly ash, red mud and calcium sulfate evenly in a certain proportion, so that the mass ratio of aluminum to silicon is 1.2:1, and the molar ratio of calcium to aluminum is 1:1;

[0041] (2) Calcination activation: calcining the mixed material at 1200°C for 150min;

[0042] (3) Acid leaching: After grinding the calcined clinker, it is leached with 1mol / L sulfuric acid, leached at a temperature of 90°C for 60 minutes, and separated from solid and liquid to obtain aluminum sulfate crude liquid. The leaching rate of alumina is 90.30%;

[0043] (4) Calcium removal: Concentrate and crystallize the filtrate to precipitate calcium sulfate crystals, and dry and recycle the precipitate after filtration;

[0044] (5) Iron removal...

Embodiment 3

[0048] In this embodiment, the content of alumina in fly ash is 38.04%, the content of silica is 42.91%, the content of alumina in red mud is 25.90%, and the content of silica is 19.68%. The specific process is as follows:

[0049] (1) Ingredients: Mix and grind fly ash, red mud and calcium sulfate evenly in a certain proportion, so that the mass ratio of aluminum to silicon is 1.3:1, and the molar ratio of calcium to aluminum is 1.4:1;

[0050] (2) Calcination activation: calcining the mixed material at 1200°C for 120min;

[0051] (3) Acid leaching: After grinding the calcined clinker, it is leached with 2mol / L sulfuric acid, leached at 90°C for 30 minutes, separated from solid and liquid to obtain aluminum sulfate crude liquid, and the leaching rate of alumina is 96.30%;

[0052] (4) Calcium removal: Concentrate and crystallize the filtrate to precipitate calcium sulfate crystals, and dry and recycle the precipitate after filtration;

[0053] (5) Iron removal: add 30% hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com