Dry-screening pre-selecting waste-discarding mineral separation technology for monohydrallite with low alumina silica ratio

An aluminum-silicon ratio and bauxite technology, which is applied in the field of low-aluminum-silicon ratio bauxite dry-screening, pre-selection and discarding waste beneficiation technology, can solve the problems of bauxite flotation not achieving good results, and save equipment and equipment. The effect of civil construction investment, reduction of energy consumption and steel ball consumption, and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

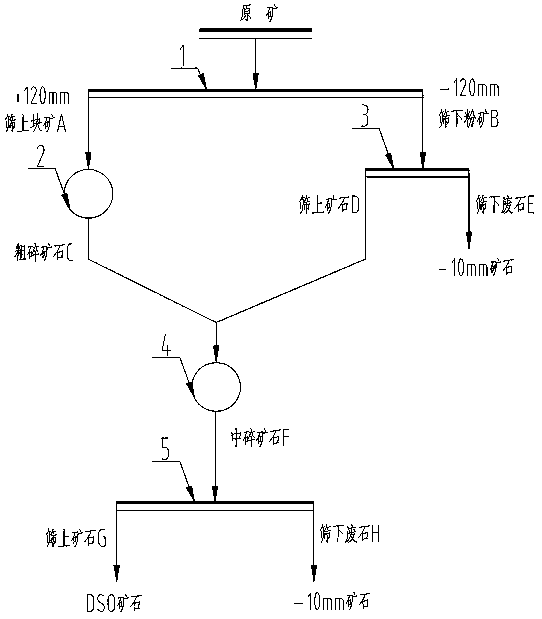

[0025] Such as figure 1 As shown, according to the present invention, a low-aluminum-silicon ratio bauxite dry screening process is realized in this way, the stope is transported to the dressing plant and the low-alumina-silicon ratio bauxite raw ore is passed through a bar screen (1) to The raw ore is divided into oversize lump ore A and undersize powder ore B. The oversize lump ore A is sent to the jaw crusher (2) for coarse crushing to obtain coarsely crushed ore C; the undersize ore B is fed into the first vibrating Sieve (3) carries out the first stage of dry sieving to obtain the above-sieve ore D and the under-sieve waste rock E. The under-sieve waste rock E is transported to the waste rock yard, and the above-sieve ore D and coarsely crushed ore C are combined and sent to the cone crushing Machine (4) carries out secondary crushing to obtain secondary crushed ore F; secondary crushed ore F is fed into the second vibrating screen (5) for the second stage of dry screenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com