Pretreatment method in the process of preparing titanium dioxide by reusing acidolysis residues

A technology of acidolysis slag and titanium dioxide, which is applied to chemical instruments and methods, titanium compounds, titanium dioxide, etc., can solve the problems of fast reaction speed, reduced acidolysis rate, large investment and cost, etc., and achieves improved recovery rate and reduced stacking The effect of slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

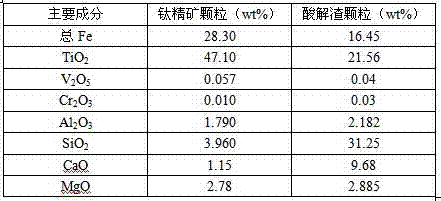

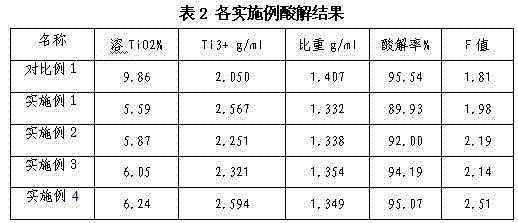

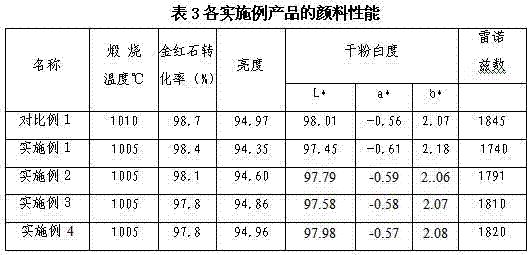

Embodiment 1

[0034] According to the total acid ore ratio of 0.6 and the reaction acid concentration of 60%, first put 792 grams of concentrated waste acid with a mass fraction of 50% into a 5000mL beaker, add 1000g of dry acid hydrolysis slag particles while stirring, and keep stirring after 10 minutes Add 208 grams of 98% concentrated sulfuric acid, then heat the material to boiling, control the heating rate, so that the acidolysis is in a slightly boiling state, the reaction temperature is 130-140 ° C, the reaction time is about 35 minutes to form a solid phase mixture, stop heating and the reaction is over , put the obtained solid-phase mixture at 160°C for 2 hours, add 1500mL of water for leaching, maintain the leaching temperature at 70°C, add 12g of iron powder after leaching for 2.5h and continue leaching for 1.5h to obtain about 3000g of acid solution , the acid hydrolysis results are shown in Table 2.

[0035] Get 3000g of the acidolysis solution obtained in Comparative Example 1...

Embodiment 2

[0038] According to the total acid ore ratio of 0.7 and the reaction acid concentration of 70%, first put 583 grams of concentrated waste acid with a mass fraction of 50% into a 5000mL beaker, add 1000g of dry acid hydrolysis slag particles while stirring, and keep stirring after 10 minutes Add 417 grams of 98% concentrated sulfuric acid, then heat the material to boiling, control the heating speed, make the acidolysis proceed in a slightly boiling state, keep the reaction temperature at about 140-150°C, and the reaction time is about 30 minutes to form a solid phase mixture, stop After the heating reaction is over, the obtained solid phase mixture is aged at 160°C for 2 hours, then add 1500mL of water for leaching, maintain the leaching temperature at 70°C, add 12g of iron powder after leaching for 2.5h and continue leaching for 1.5h to obtain acid The solution solution is about 3000g, and the acid hydrolysis results are shown in Table 2.

[0039] Get the acid solution soluti...

Embodiment 3

[0042] According to the total acid ore ratio of 0.7 and the reaction acid concentration of 80%, first put 328 grams of concentrated waste acid with a mass fraction of 50% into a 5000mL beaker, add 1000g of dry acid hydrolysis slag particles while stirring, and keep stirring after 10 minutes Add 547 grams of 98% concentrated sulfuric acid, then heat the material to boiling, control the heating rate, so that the acidolysis is carried out in a slightly boiling state, the temperature should be 150-160 ° C, the reaction time is about 25 minutes to form a solid phase mixture, and stop the heating reaction At the end, put the obtained solid-phase mixture at 160°C for 2 hours, add 1500mL of water for leaching, maintain the leaching temperature at 70°C, add 12g of iron powder after leaching for 2.5h and continue leaching for 1.5h to obtain acidolysis solution About 3000g, the results of acid hydrolysis are shown in Table 2.

[0043] Get the acid solution 5000g obtained in comparative e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com