Heavy-type combustion engine high-temperature turbine double-medium cooling blade

A technology for cooling blades and duplexes, which is applied in the cooling of turbines/propulsion devices, cooling of engines, and supporting components of blades, etc., which can solve problems such as low efficiency, uneven distribution, and complex blade structure of gas turbines, and achieve improved Thermal efficiency, enhanced heat transfer effect, uniform temperature distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

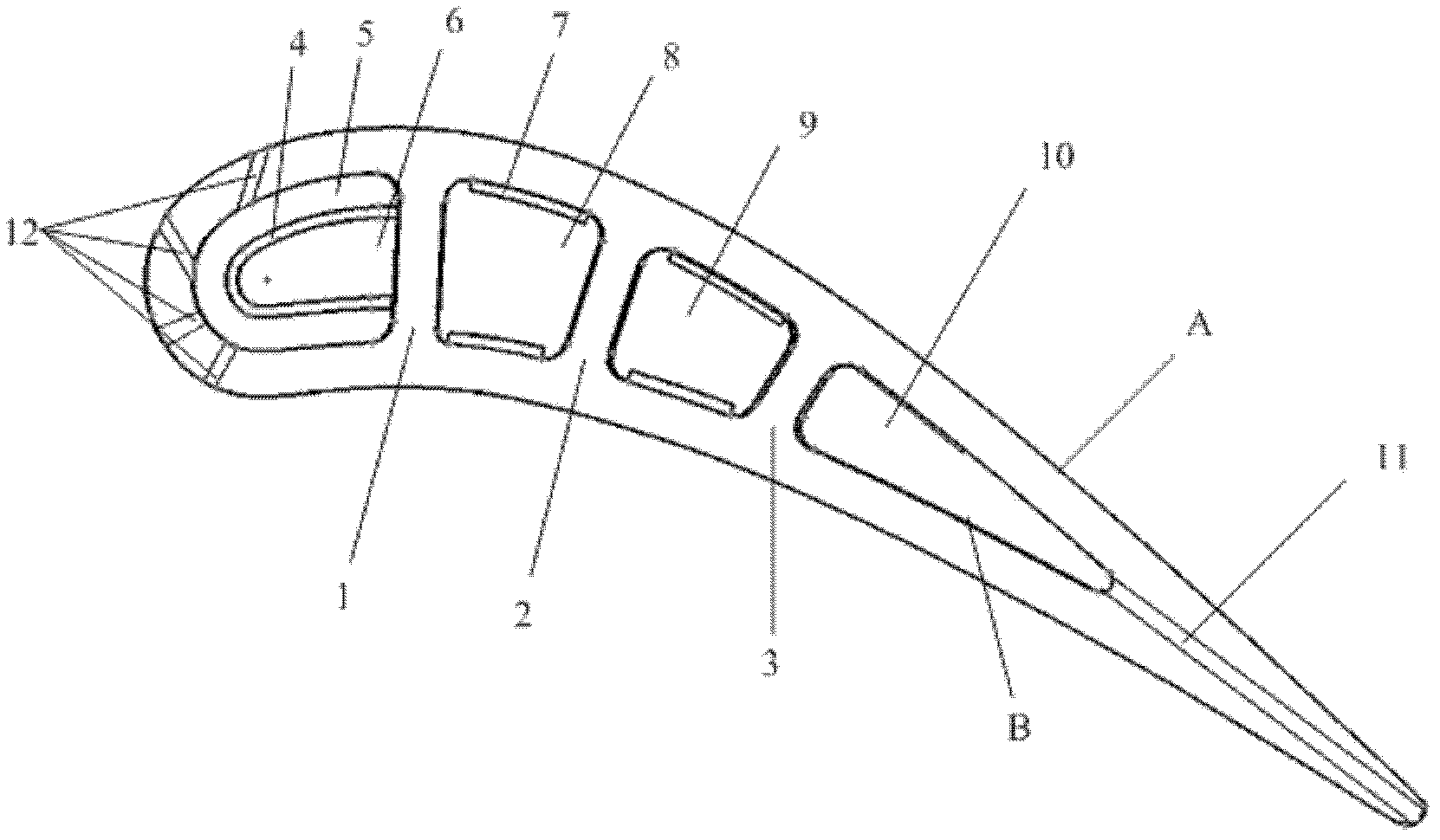

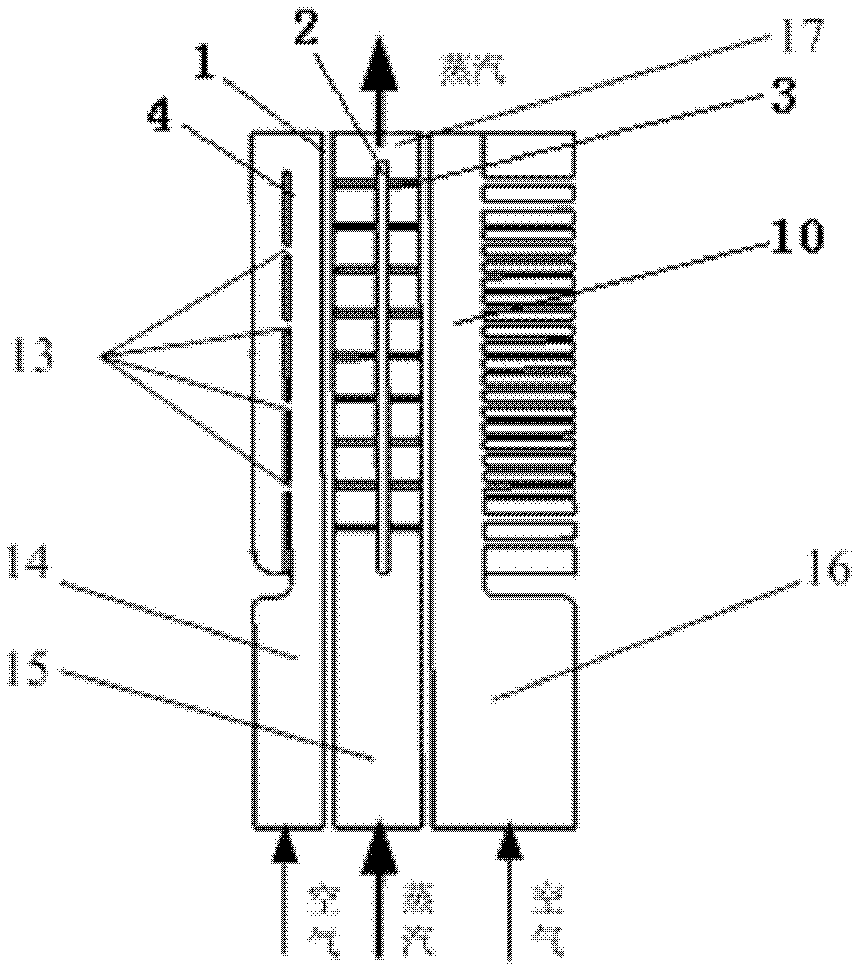

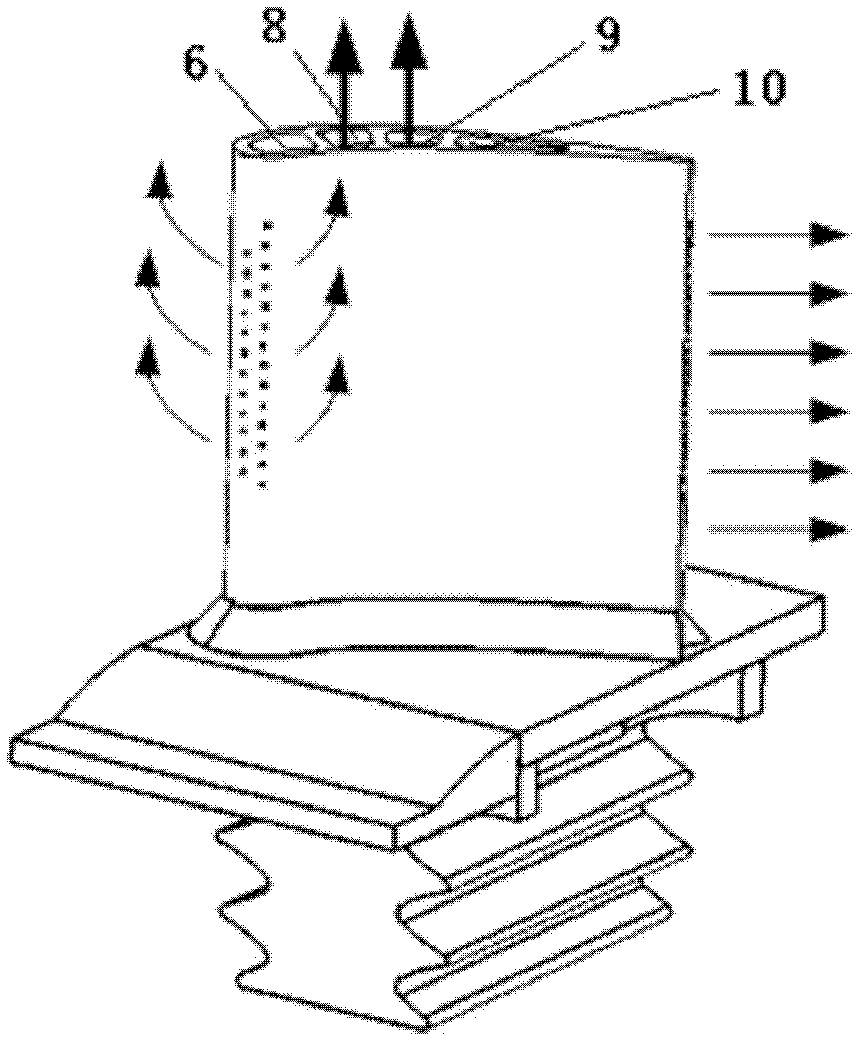

[0024] refer to figure 1 , figure 2 and Figure 4 , according to the aerodynamic parameters, the shape line of the outer wall A of the blade is composed of four parts: the leading edge, the trailing edge, the pressure edge and the suction edge. The pressure side and suction side are defined by high-order Bezier curves, and the leading edge and trailing edge of the blade are connected by arcs, and the connection is second-order differentiable. The positions of the pressure side and the suction side are both defined by their relative positions to the mid-arc, and the mid-arc is defined by a second-order Bezier curve. The high-order Bezier curves defining the pressure side and the suction side are controlled by parameters such as the leading edge radius control point, the trailing edge radius control point, the outlet edge wedge angle control point, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com