A heat press machine for reinforced composite flooring

A technology of strengthening composite floor and hot press, which is applied in the direction of plywood press, veneer press, manufacturing tool, etc. Uneven distribution, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

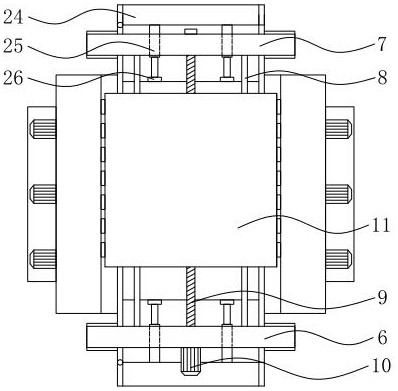

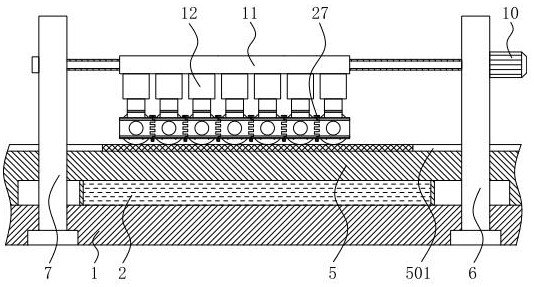

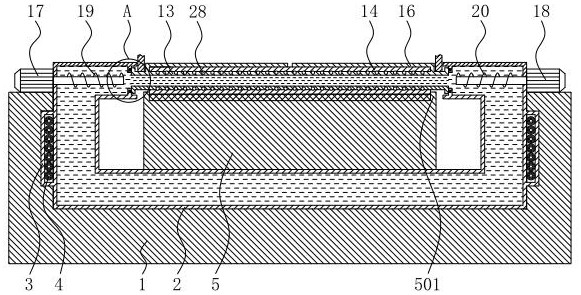

[0029] Such as Figure 1 to Figure 6As shown, this embodiment provides a heat press machine for reinforced composite flooring, which includes a base 1 on which an oil storage tank 2 is fixedly installed. The part is bent, and the end faces 201 on both sides of the oil storage tank 2 are parallel to each other. Three pairs of through holes 202 corresponding to each other are provided on the two end faces 201 at equal intervals along the length direction thereof. A sealed heating cavity 3 is fixedly installed on the outer wall of the oil storage tank 2 , and a heating wire 4 is arranged in the heating cavity 3 . The air in the heating chamber 3 is heated by the heating wire 4 , and the air in the heating chamber 3 transfers heat to the oil stored in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com