Dual-fluid spraying gun structure suitable for flue-type urea direct injection pyrolysis process

A dual-fluid spray gun, urea technology, applied in liquid spray devices, spray devices, separation methods, etc., can solve the problems of increasing initial investment cost and operating power consumption, and achieve the effects of improving atomization effect, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below in conjunction with accompanying drawing:

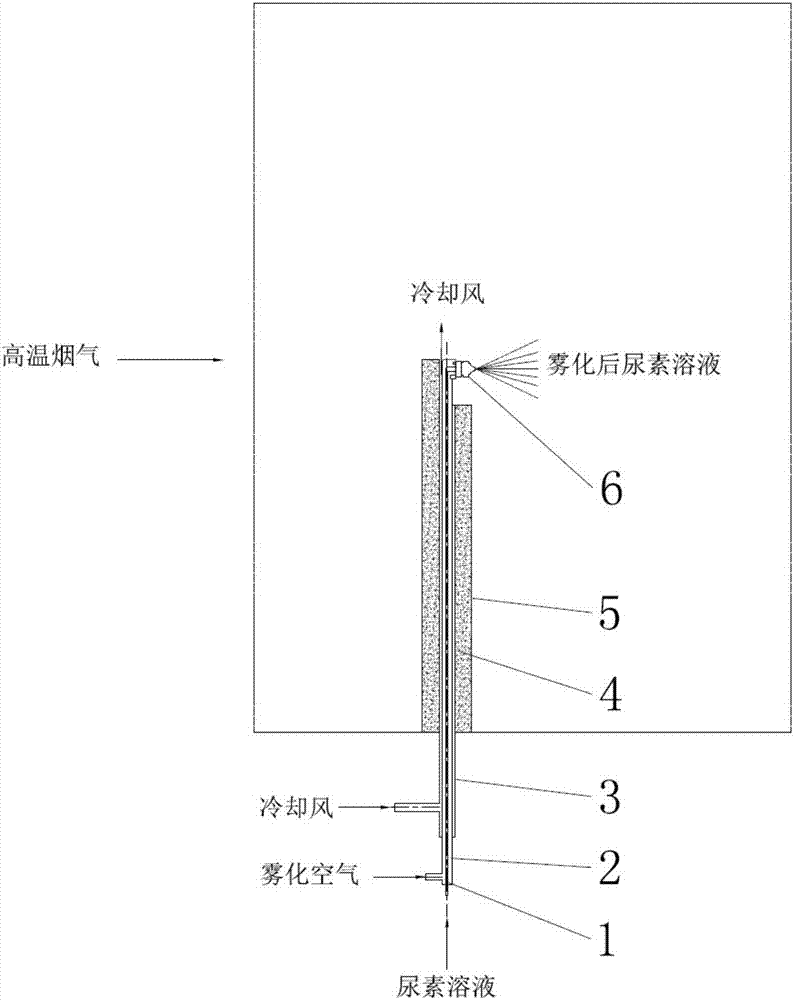

[0017] The dual-fluid spray gun structure applicable to the flue-type urea direct injection pyrolysis process of the present invention includes a gun shaft and an atomizing nozzle 6, wherein the gun shaft includes a cooling air pipeline 3, an atomizing air pipeline 2 and a urea solution pipeline 1; The solution pipeline 1, the atomizing air pipeline 2 and the cooling air pipeline 3 are distributed sequentially from the inside to the outside, wherein, the side of one end of the cooling air pipeline 3 is provided with a cooling air inlet, and the side of one end of the atomizing air pipeline 2 is provided with an atomizing air inlet , the atomizing nozzle 6 is fixed on the side of the other end of the cooling air pipeline 3, the atomizing air inlet of the atomizing nozzle 6 is connected with the other end of the atomizing air pipeline 2, the urea solution inlet of the ato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com