Combined fluidized bed type gas-solid heat exchange device utilizing waste heat of furnace slag

A heat exchange device and composite flow technology, applied in fluidized bed heat exchangers, indirect heat exchangers, heat exchanger types, etc., can solve the problems of inability to recover slag heat, high additional energy consumption, large water resources, etc. , to extend the residence heat exchange time, ensure the cooling effect, and improve the adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

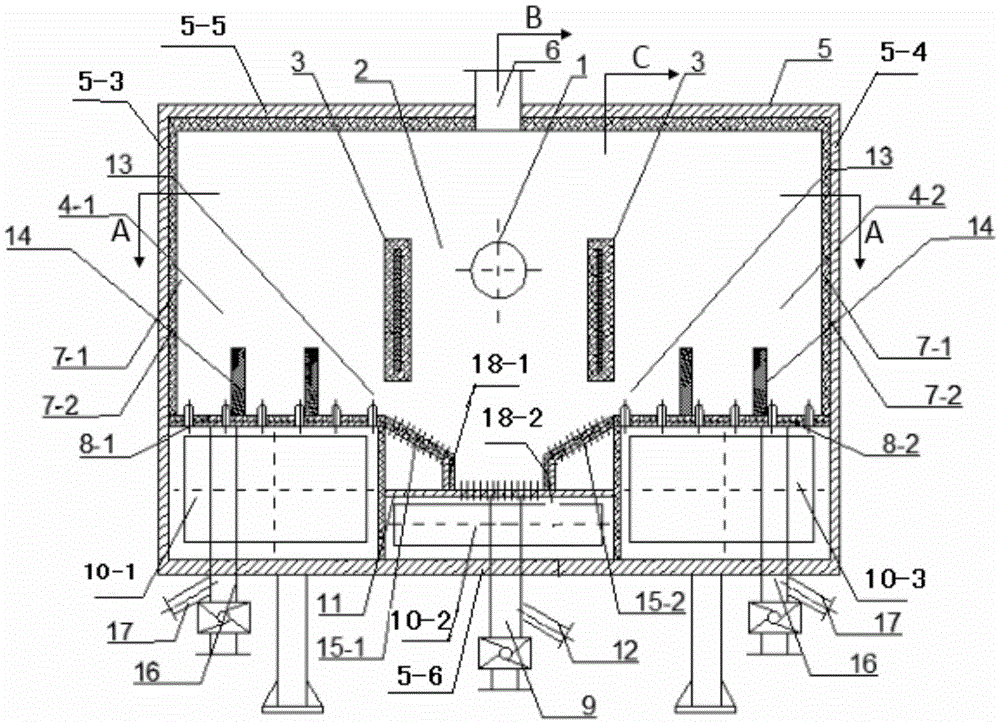

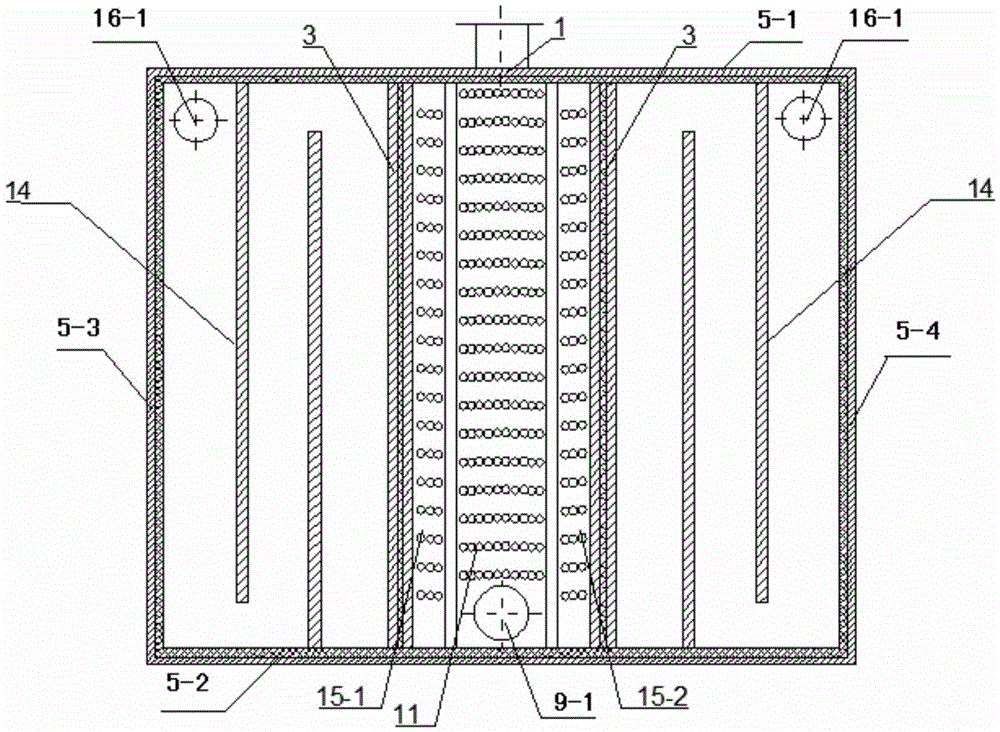

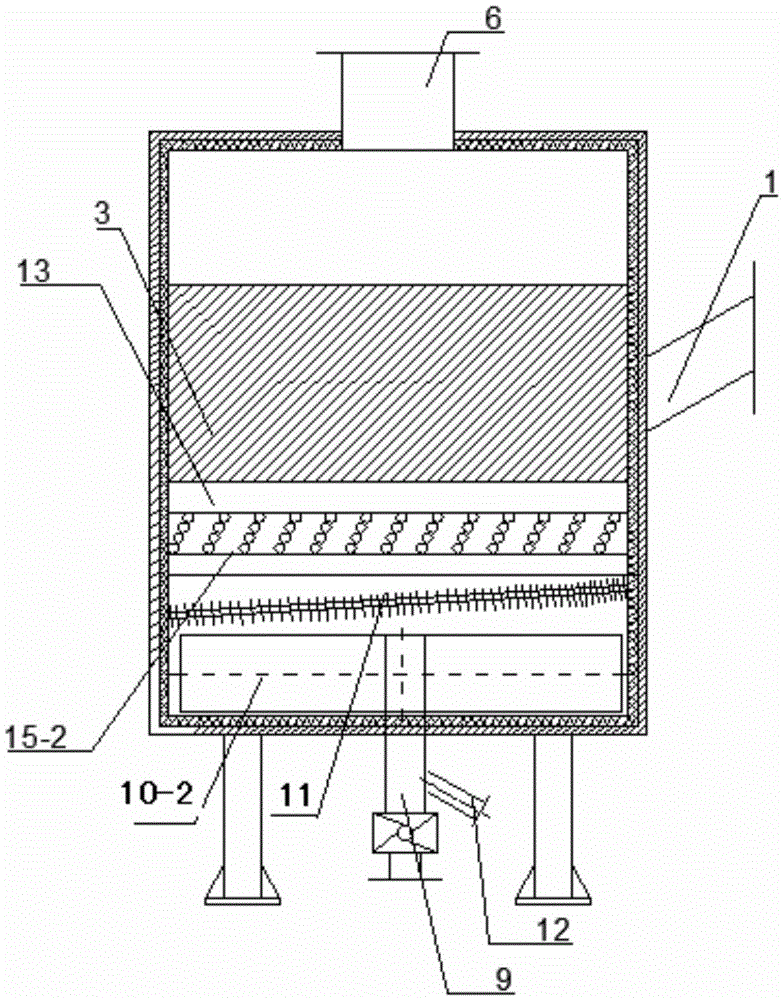

[0015] The following is attached with the manual Figure 1 to Figure 4 The device of the present invention is described in detail.

[0016] A composite fluidized bed gas-solid heat exchange device utilizing waste heat from slag, including a gas-solid heat exchange body 5, the gas-solid heat exchange body 5 includes a front panel 5-2, a rear panel 5-1, a left panel 5-3, and a right panel 5-4, the top plate 5-5 and the bottom plate 5-6; the top of the gas-solid heat exchange main body 5 is provided with an air outlet 6; the gas-solid heat exchange main body 5 is arranged in a direction parallel to the left panel 5-3 and the right panel 5-4 There are two partition walls 3, both of which are connected to the front panel and rear panel of the gas-solid heat exchange body 5, and divide the internal chamber of the gas-solid heat exchange body 5 into the left bubbling bed chamber 4-1, the spray The bed compartment 2 and the right bubbling bed compartment 4-2, the left and right bubbl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com