Preparation method of highly-textured Ti2AlN ceramics

A textured and highly advanced technology, applied in the field of preparation of highly textured Ti2AlN ceramics, can solve the problems of insignificant orientation effect, high equipment requirements, high equipment energy consumption, etc. Equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

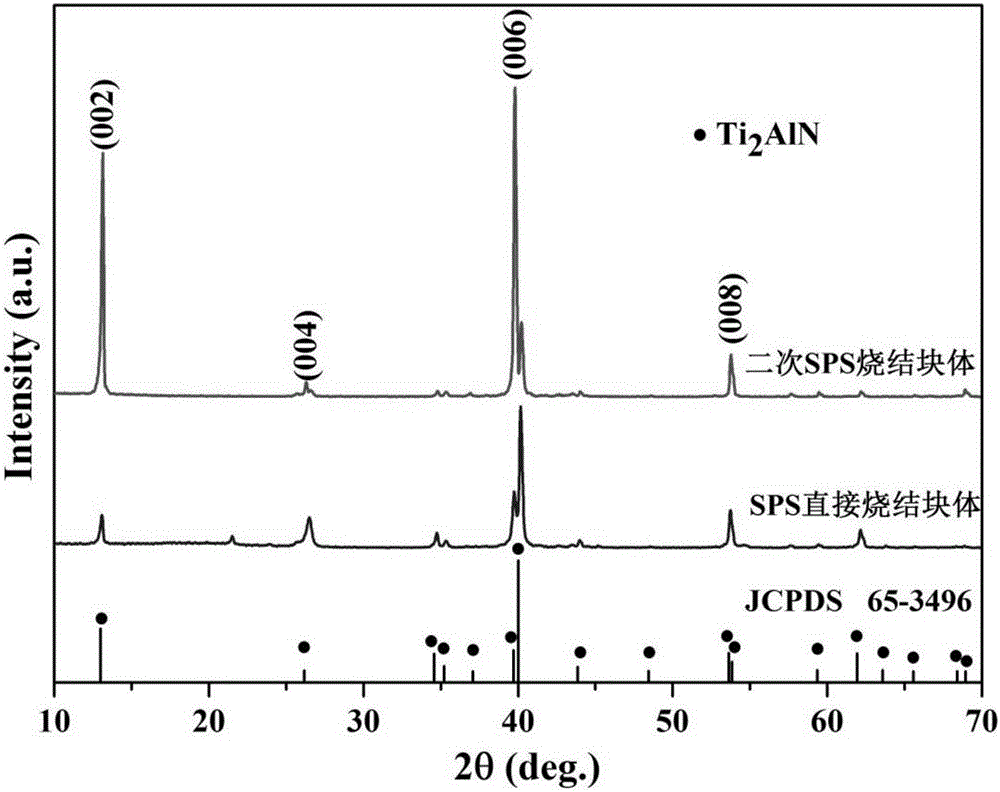

Embodiment 1

[0018] Step 1: Use the powder with a molar ratio of Ti:Al:TiN=1.5:1.5:1 as the initial raw material, the ball milling medium is alcohol, the ratio of material to ball is 1:2, and the speed is 300rpm. After 4 hours of ball milling, it is cold pressed and formed Thermal explosion reaction sintering is carried out in the discharge plasma sintering equipment, the sintering temperature is 650°C, and after holding for 2 minutes, it is rapidly cooled and the oxide layer on the surface of the green body is ground off, crushed and passed through a 300-mesh sieve to obtain Ti 2 AlN ceramic powder;

[0019] Step 2: Take a certain amount of Ti 2 Fill the AlN ceramic powder into a mold with a diameter of 12mm and perform discharge plasma pre-sintering in an ordinary box furnace. The initial temperature is room temperature. When the sintering temperature reaches 900°C, uniaxially pressurize to 40MPa and then cool directly;

[0020] Step 3: Put the sintered green body obtained in Step 2 int...

Embodiment 2

[0022] Step 1: Use the powder with a molar ratio of Ti:Al:TiN=1.1:1.1:1 as the initial raw material, the ball milling medium is alcohol, the ratio of material to ball is 1:3, and the speed is 400rpm. After 4 hours of ball milling, it is cold pressed and formed Thermal explosion reaction sintering is carried out in the discharge plasma sintering equipment, the sintering temperature is 700°C, after 2 minutes of heat preservation, it is rapidly cooled and the oxide layer on the surface of the green body is ground off, crushed and passed through a 300-mesh sieve to obtain Ti 2 AlN ceramic powder;

[0023] Step 2: Take a certain amount of Ti 2 Fill the AlN ceramic powder into a mold with a diameter of 12mm and perform discharge plasma pre-sintering in an ordinary box furnace. The initial temperature is room temperature. When the sintering temperature reaches 950°C, uniaxially pressurize to 30MPa and cool directly;

[0024] Step 3: Put the sintered green body obtained in Step 2 int...

Embodiment 3

[0027] Step 1: Use the powder with a molar ratio of Ti:Al:TiN=1:1:1 as the initial raw material, the ball milling medium is alcohol, the ratio of material to ball is 1:3, and the speed is 200rpm. After 4 hours of ball milling, it is cold pressed and formed Thermal explosion reaction sintering is carried out in the discharge plasma sintering equipment, the sintering temperature is 900°C, and after holding for 2 minutes, it is rapidly cooled and the oxide layer on the surface of the green body is ground off, crushed and passed through a 300-mesh sieve to obtain Ti 2 AlN ceramic powder;

[0028] Step 2: Take a certain amount of Ti 2 Fill the AlN ceramic powder into a mold with a diameter of 18mm and perform discharge plasma pre-sintering in an ordinary box furnace. The initial temperature is room temperature. When the sintering temperature reaches 1100°C, uniaxially pressurize to 50MPa and then cool directly;

[0029] Step 3: Put the sintered green body obtained in Step 2 into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com