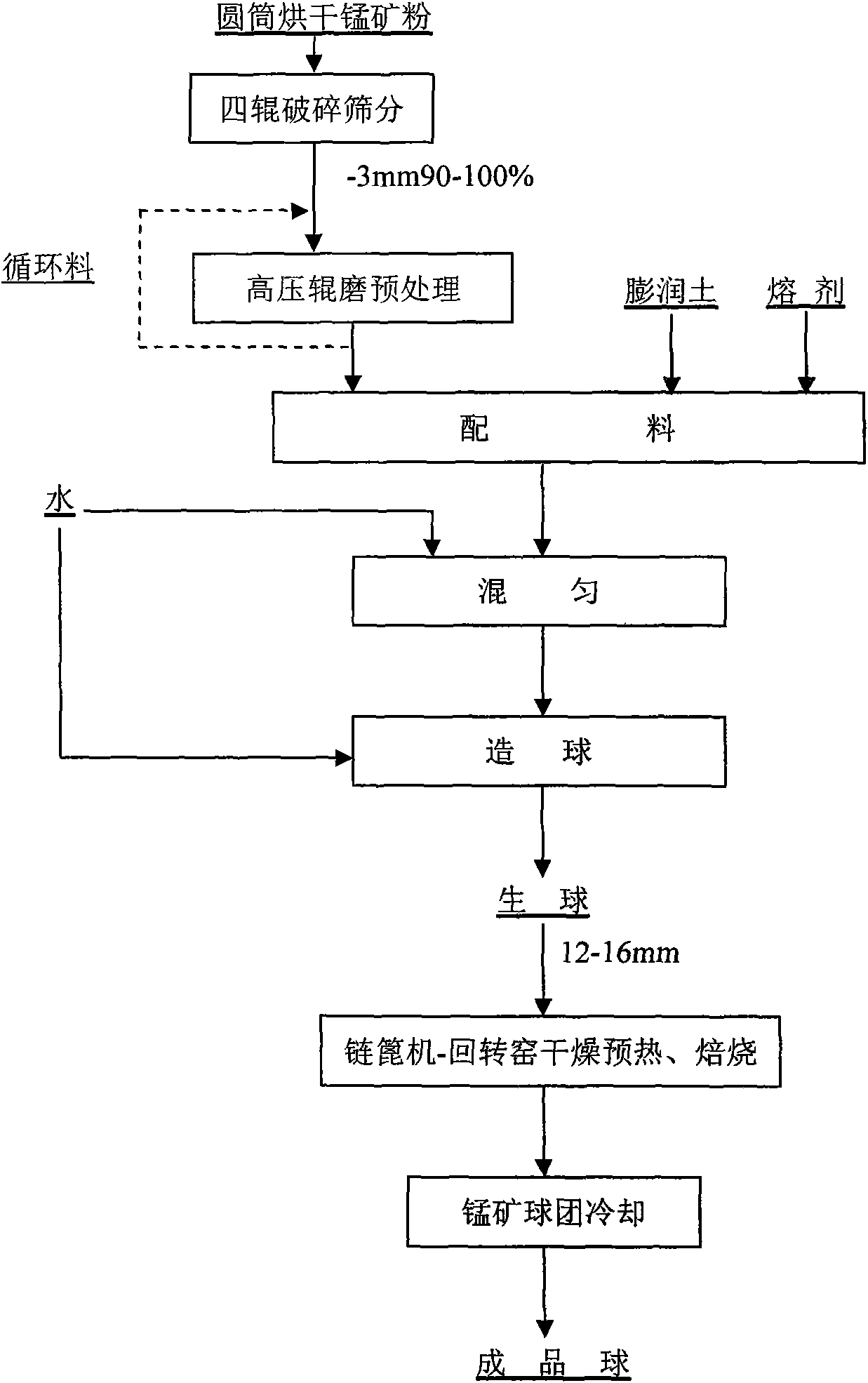

Complex manganese ore powder pelletization process

A technology of manganese ore powder and pellets, which is applied in the field of iron and steel metallurgy, can solve the problems of low strength of pellets, coarse particle size of manganese powder ore, and poor thermal stability, and achieve the effects of reducing energy consumption, high manganese grade, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: The pretreatment method is to sieve and crush high-crystal manganese powder ore with a four-roller crusher to a particle size of -3mm, accounting for 90%, and then roll twice through a high-pressure roller mill at a material moisture content of 8.2%. Pressure 0.83MPa. When making pellets, the amount of bentonite used is 2.0% of the mass of manganese powder ore, the pelletizing time is 6 minutes, the water content of raw pellets is 16±0.5%, and the natural alkalinity is 0.17. Grate machine-rotary kiln conditions are: grate cloth height 220mm, blast drying wind speed 1.6m / s, blast drying time 2min, blast drying temperature 200℃, draft drying wind speed 1.6m / s, draft drying time 5min , Air extraction drying temperature 350°C, preheating stage 1 wind speed 2.4m / s, time 4min, temperature 700°C, preheating stage 2 wind speed 2.4m / s, time 15min, temperature 1050°C, roasting temperature 1330°C, time 15min. The results of the manganese ore pellets obtained are as fol...

Embodiment 2

[0018] Example 2: The pretreatment method is to sieve and crush the high-crystal manganese powder ore with a roller crusher until the particle size is -3mm, which accounts for 100%, and then roll once through the high-pressure roller mill under the material moisture of 8%, and the rolling pressure 1MPa. When making pellets, the amount of bentonite is 2.0%, the pelleting time is 8 minutes, the water content of raw pellets is 16±0.5%, and the natural alkalinity is 0.17. Grate machine-rotary kiln conditions are: grate cloth height 220mm, blast drying wind speed 1.6m / s, blast drying time 2min, blast drying temperature 200℃, draft drying wind speed 1.6m / s, draft drying time 5min , Air extraction drying temperature 350°C, preheating stage 1 wind speed 2.4m / s, time 4min, temperature 500°C, preheating stage 2 wind speed 2.4m / s, time 15min, temperature 1050°C, roasting temperature 1340°C, time 20min. The results of the manganese ore pellets obtained are as follows: the compressive str...

Embodiment 3

[0019]Example 3: The pretreatment method is to sieve and crush the high-crystal manganese powder ore with a roller crusher to a particle size of -3mm, which accounts for 100%, and then roll twice through a high-pressure roller mill under a material moisture of 8%. Pressure 0.83MPa. When making pellets, the amount of bentonite is 2.0%, the pelleting time is 6 minutes, the water content of raw pellets is 16±0.5%, and the alkalinity R=0.7. Grate machine-rotary kiln conditions are: grate cloth height 220mm, blast drying wind speed 1.6m / s, blast drying time 2min, blast drying temperature 150℃, draft drying wind speed 1.6m / s, draft drying time 5min , Air extraction and drying temperature 200°C, preheating stage 1 wind speed 2.4m / s, time 4min, temperature 600°C, preheating stage 2 wind speed 2.4m / s, time 15min, temperature 1080°C, roasting temperature 1330°C, time 15min. The results of manganese ore pellets obtained are as follows: the compressive strength of the preheated ball is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com