Patents

Literature

32results about How to "Speed up roasting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

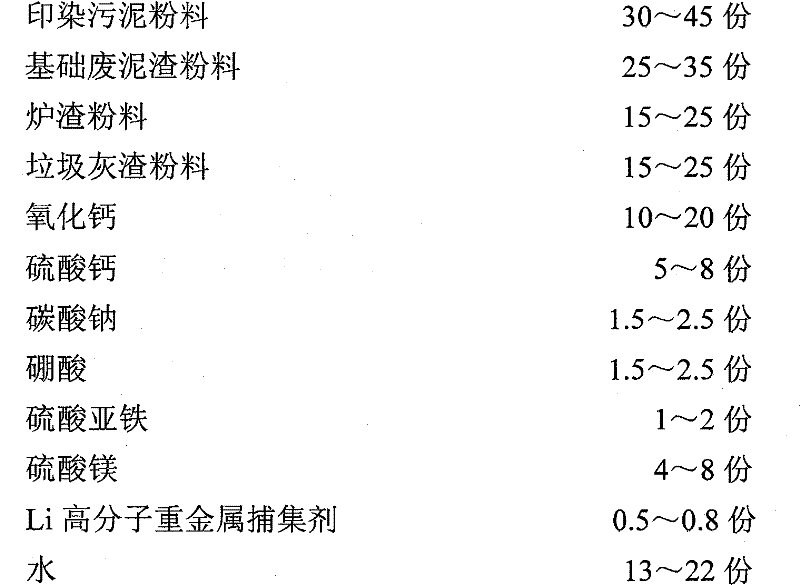

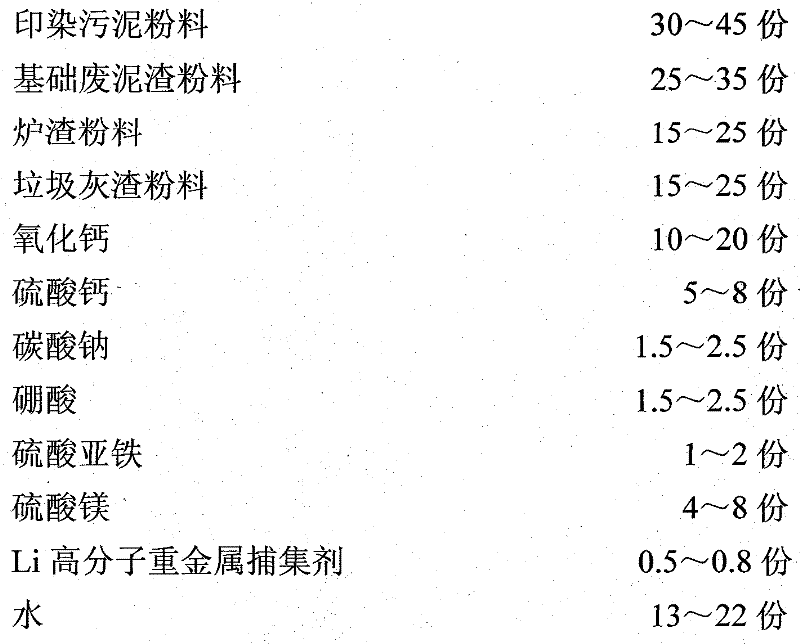

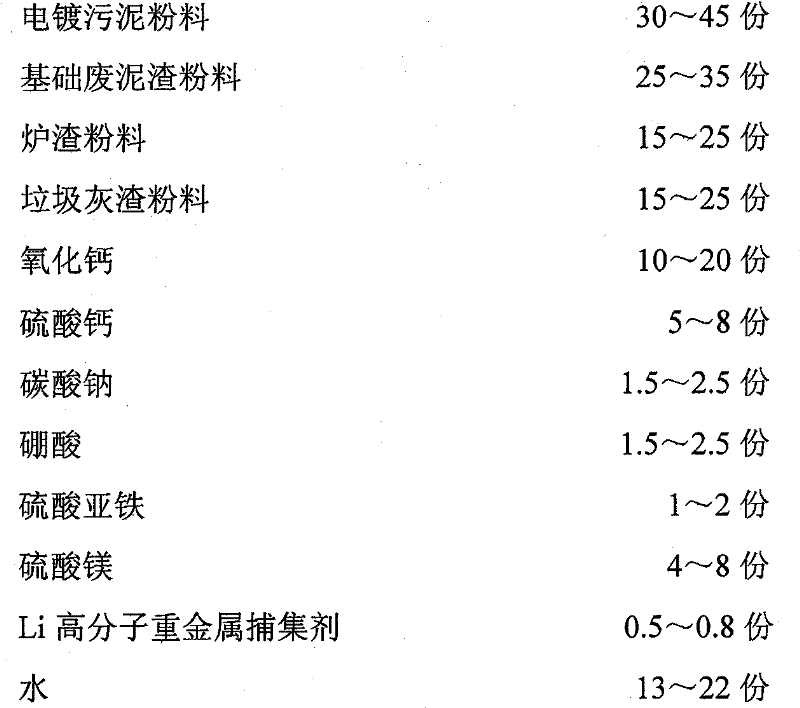

Sintered light-weight environment-friendly brick produced from electroplating sludge and manufacture method thereof

The invention relates to a sintered light-weight environment-friendly brick produced from electroplating sludge and a manufacture method thereof. The sintered light-weight environment-friendly brick is characterized by being prepared by adopting electroplating sludge, base waste sludge, furnace slag, refuse ash, calcium oxide, calcium sulfate, sodium carbonate, boric acid, ferrous sulfate, magnesium sulfate, Li macromolecular heavy metal trapping agent and water are adopted as raw materials; and the manufacture method comprises the following steps of: mixing and stirring the raw materials in a biaxial mixer to be in a moisture state; extruding into rectangular bars by a vacuum sludge extruder; cutting and forming by a blank cutter; manufacturing light-weight environment-friendly brick blanks of electroplating sludge under the pressure of 20-30 MPa; and conveying the formed and naturally dried light-weight environment-friendly brick blanks into a tunnel kiln to roast and manufacture light-weight environment-friendly brick products. Air laying bricks and pavement bricks in different specifications can also be manufactured by the raw materials of the invention, and the product has the advantages and the effects of light weight, great strength, zero pollution, low cost and good benefits.

Owner:清远绿由环保科技有限公司

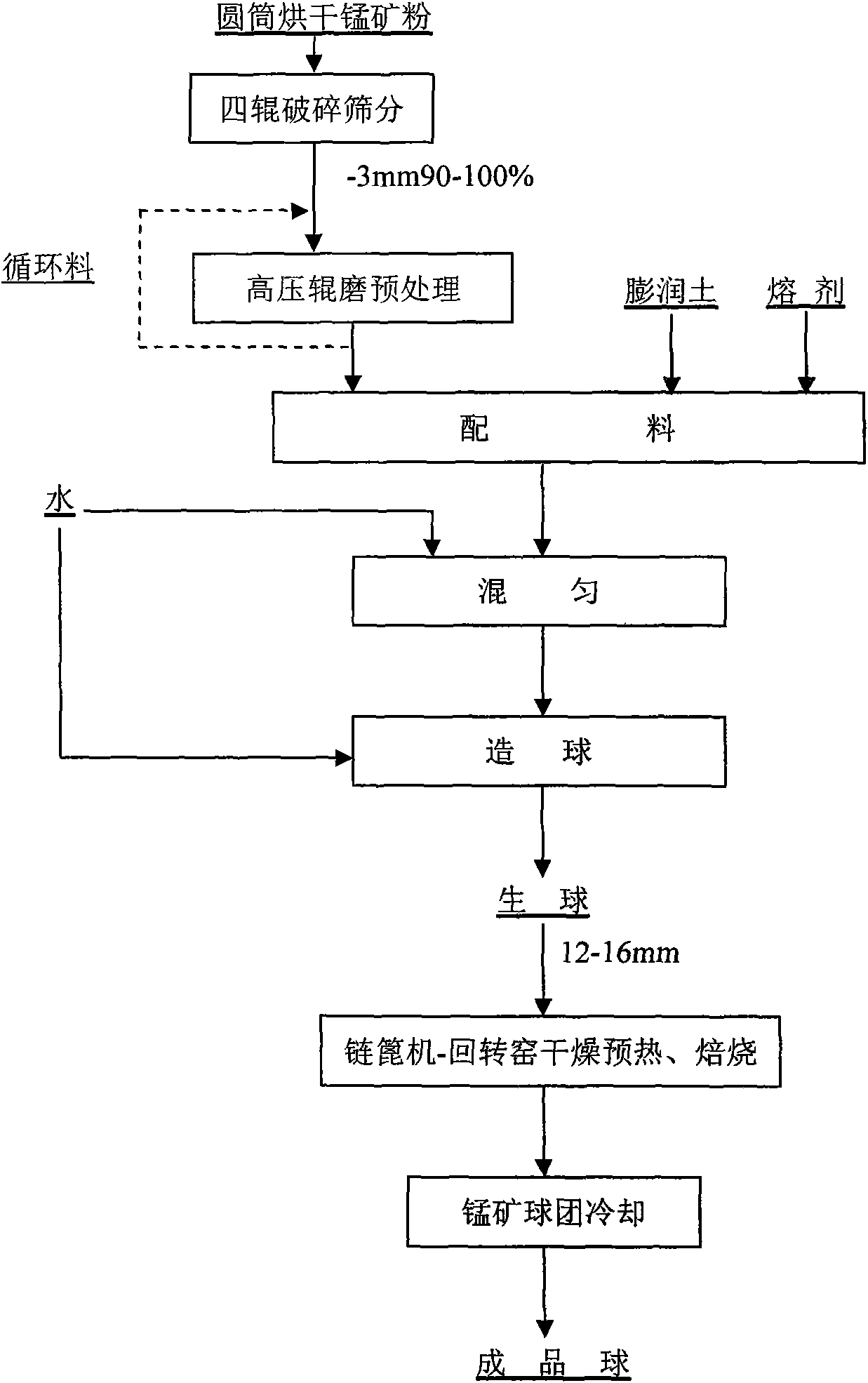

Complex manganese ore powder pelletization process

The invention relates to a complex manganese ore powder pelletization process. High-crystal-water manganese powder ore is treated by a cylindrical drier for drying, a four-roll crusher for coarse crushing and a high-pressure roller mill for fine milling pretreatment, bentonite and flux are added in finely milled manganese ore concentrate obtained after pretreatment for pelletization, green pelletsare dried and preheated on a chain-grate machine, preheated pellets enter a rotary kiln for high-temperature roasting and then is cooled to obtain a pellet product. Compared with ball milling process, the invention can reduce the energy consumption in pretreatment flow, improve the ballability index of finely milled material, eliminate thermal explosion of pellets and solve the technical problemsthat narrow manganese ore softening temperature area affects pellet roasting. The adoption of two-segment preheating effectively prevents cracks on the preheated pellets and improves the performancesof the preheated pellets; the addition of limestone or dolomite as flux changes the alkalinity and the slagging property of raw material and enhances the pellet roasting and next melting; and the produced manganese ore pellet has high strength, large output and high manganese grade.

Owner:CENT SOUTH UNIV

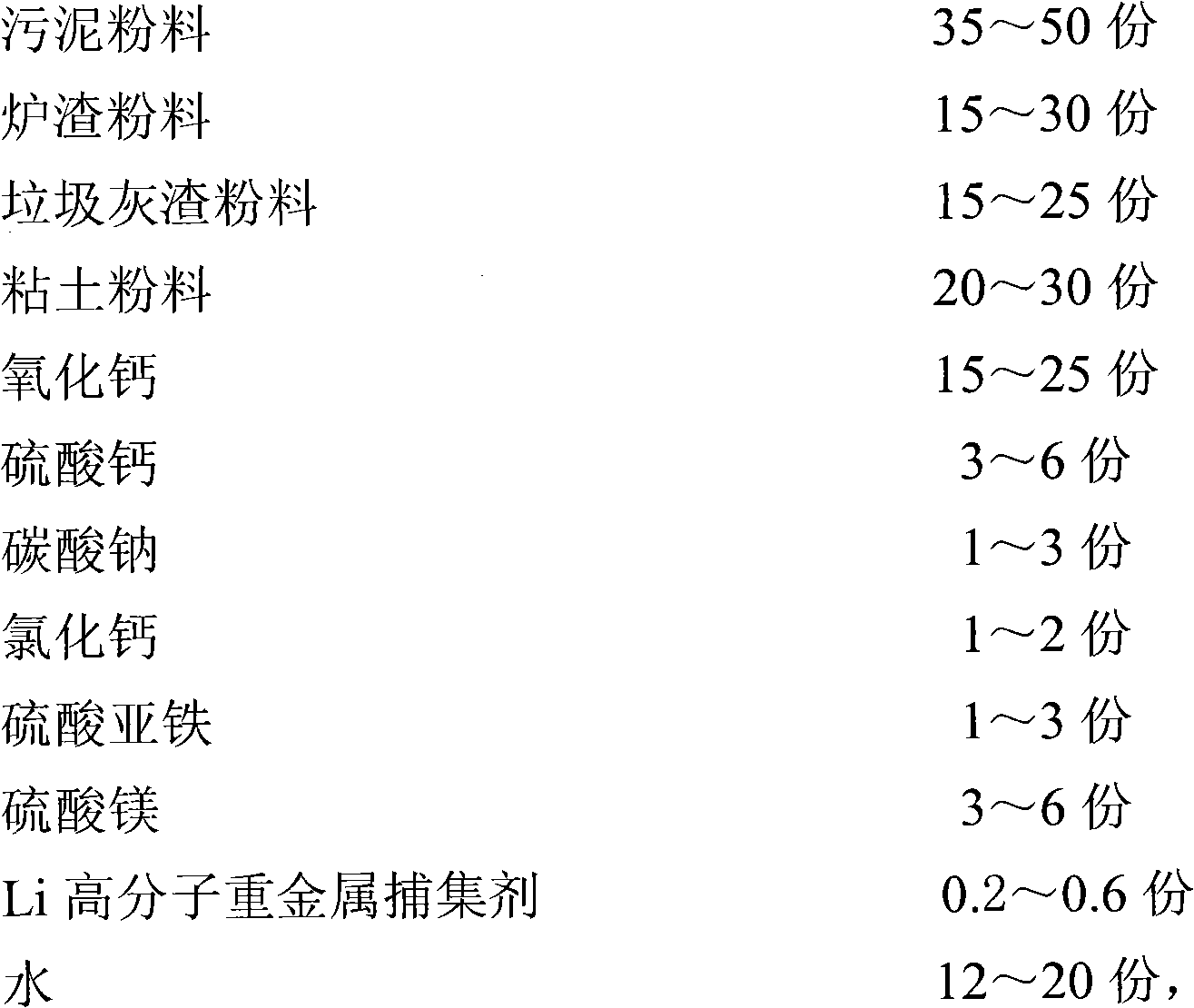

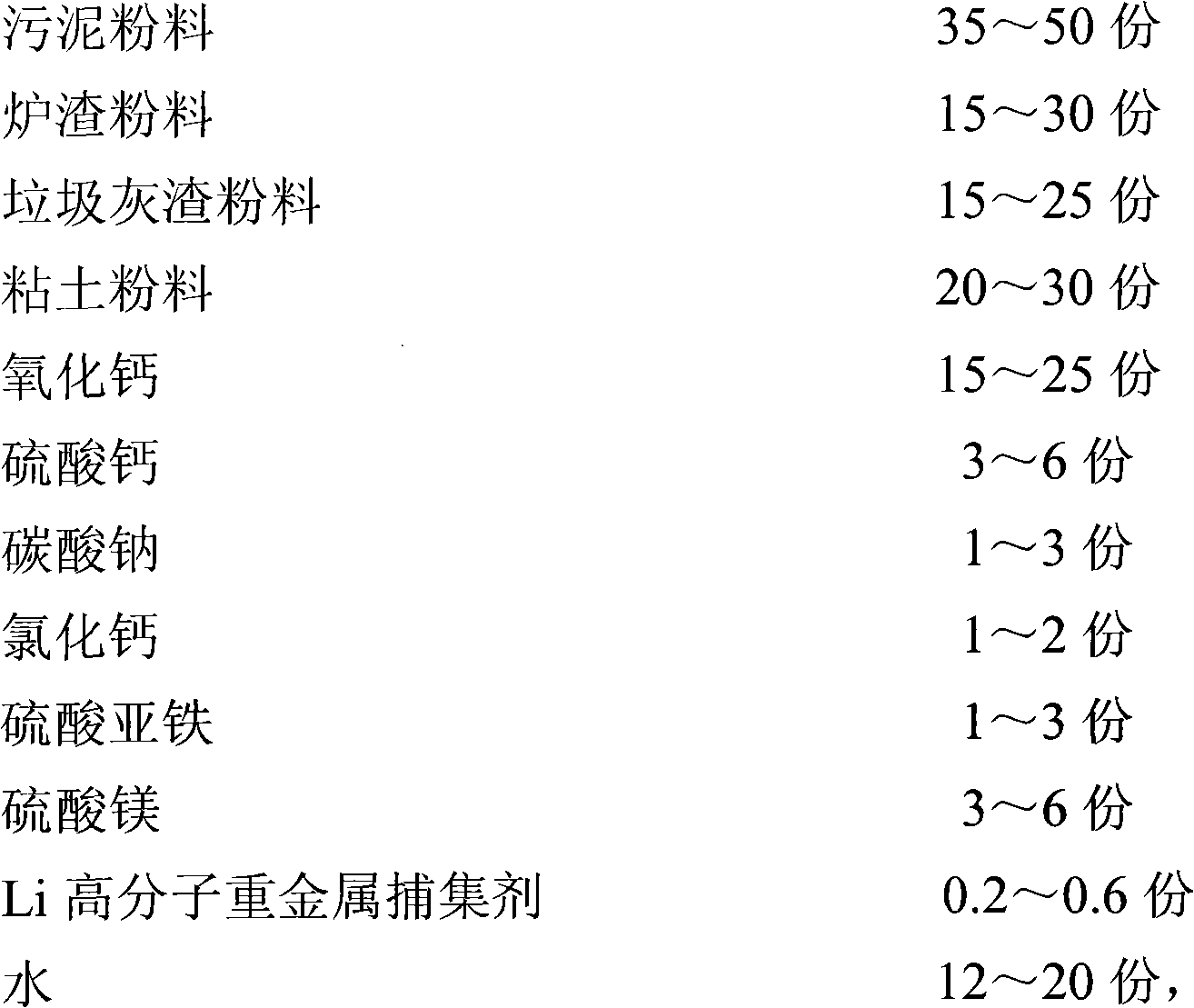

Sintered light environmental-friendly brick produced by using municipal sludge and manufacture method thereof

The invention relates to a sintered light environmental-friendly brick produced by using municipal sludge and a manufacture method thereof. The manufacture method is characterized by comprising the steps of: adding sludge, slag, rubbish ash, clay, calcium oxide, calcium sulfate, sodium carbonate, calcium chloride, ferrous sulfate, magnesium sulfate, an Li macromolecule heavy metal trapping agent and water as raw materials; mixing and stirring to be in a wet state and then extruding through an airing extruder, cutting and forming through a blanking machine; preparing a sludge light environmental-friendly brick blank under the pressure of 25-30MPa; and forming the naturally dried light environmental-friendly brick blank in an annular kiln for roasting and then preparing the light environmental-friendly brick. According to the invention, different specifications of building-blocks and sidewalk bricks can be manufactured by using the raw materials. The sintered light environmental-friendly brick has the advantages and effects of light weight, high strength, no pollution, low cost and good benefit.

Owner:清远绿由环保科技有限公司

Regenerated brick prepared from papermaking sludge and preparation method thereof

InactiveCN103130492AHigh densityIncrease profitCeramic materials productionClaywaresBreaking strengthBrick

The invention relates to a regenerated brick prepared from papermaking sludge and a preparation method thereof. the invention solves the problem of restricted utilization ratio of bricks prepared from papermaking sludge, and overcomes the defects of low compression resistance, low breaking strength, poor air permeability and the like in the bricks prepared from papermaking sludge. The preparation method comprises the following steps: mixing and stirring 35-40 parts by weight of papermaking sludge with the water content of 45-55%, 20-25 parts by weight of power plant sintering ash, 40-45 parts by weight of clay, 2.5-4 parts by weight of flame-retardant permeable fiber monofilament, 3-5 parts by weight of blind coal, 3-5 parts by weight of water-soluble resin and 4-7 parts by weight of water to obtain a wet material; and extruding with an extruding machine to obtain a blank strip, cutting into green bricks, naturally drying in air, and sintering in a kiln.

Owner:FUJIAN YIYUAN WASTE UTILIZATION

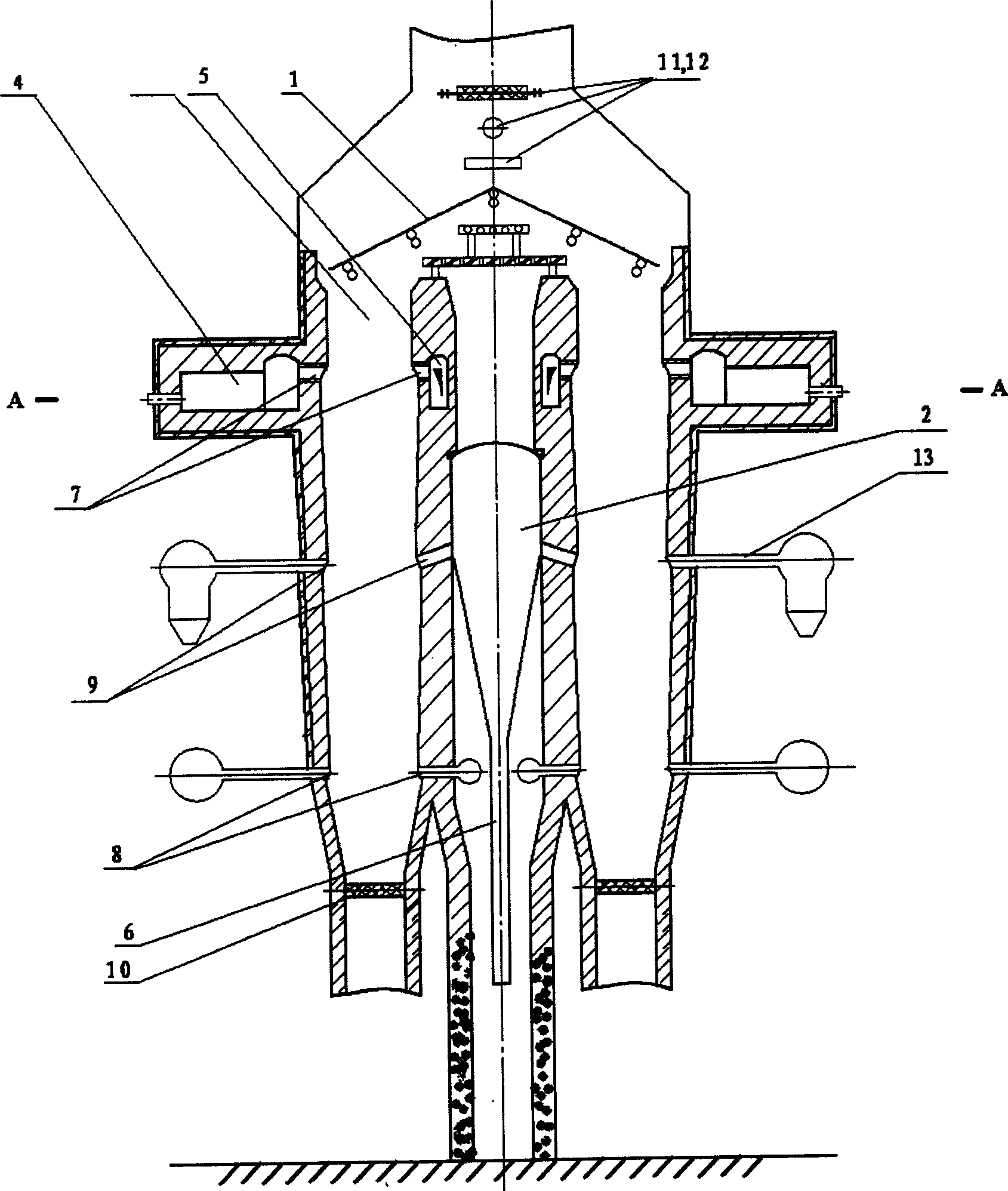

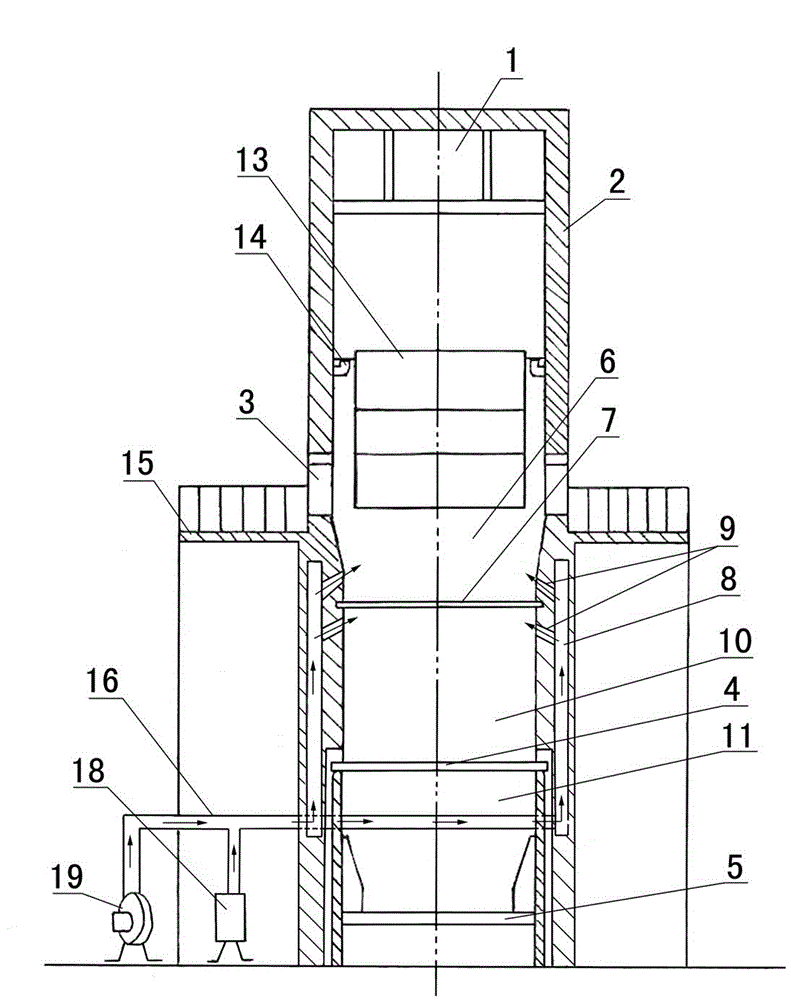

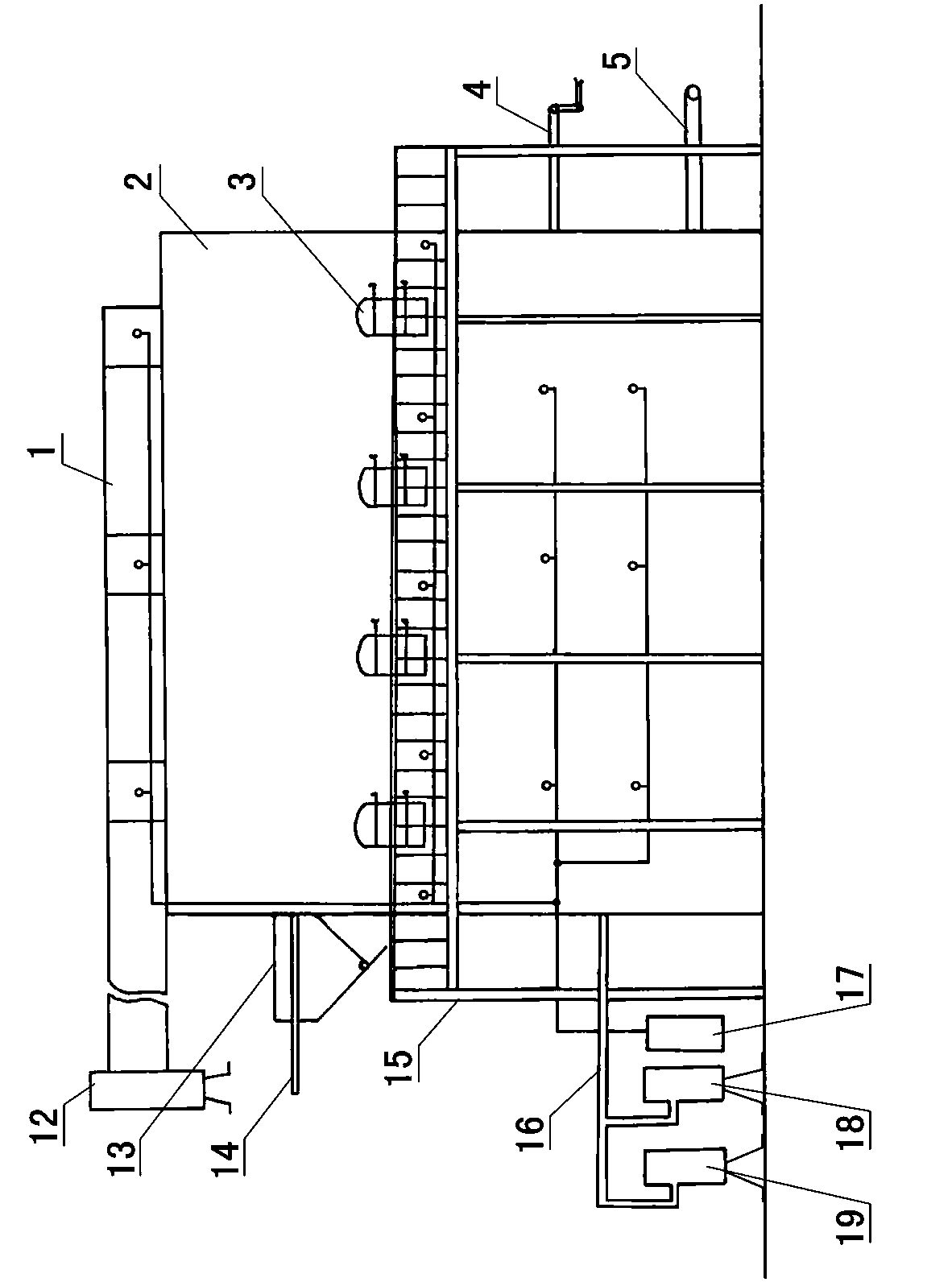

Double-blowing two-seat two-row vertical pellet-roasting furnace

The double-blowing two-seat two-row vertical pellet-roasting furnace includes stoving bed, blast guiding chamber, dust laying chamber, blast guiding pipe, combustor, roasting chamber, roasting blast distributing chamber, material laying unit, material distributing unit and pre-drying unit. It features the complex furnace form with burners on two sides of the roasting band, cooling jets on two sides of the cooling band, air exhaust ports on two sides of the end of the cooling band, dust laying chamber below the blast guiding chamber and the pellet pre-drying unit over the stoving bed. The present invention has improved heating, cooling and ventilating mechanisms of vertical furnace, and has the advantages of reinforced roasting, reinforced cooling, reinforced drying, controllable airflow motion, etc.

Owner:NORTHEASTERN UNIV

Method of preparing manganese sulfate solution by reducing pyrolusite

PendingCN110396612AEasy to handleProcess environmental protectionManganese sulfatesPyrolusiteElectrolysis

The invention discloses a method of preparing a manganese sulfate solution by reducing pyrolusite. The method comprises the following steps: (1) crushing the pyrolusite to obtain a product a; (2) adding a sulfuric acid solution into the product a, uniformly stirring the solution, and heating and insulating the solution to obtain a product b; (3) adding a reducer into the product b, and controllingthe temperature to react to obtain a product c; and (4) transferring the product c to a leaching tank, supplementing an electrolytic manganese anode solution to maintain a liquid-solid ratio, controlling the temperature, stirring the solution to react, and filtering the solution to obtain the manganese sulfate solution. Compared with an existing method of reducing carbon and acid leaching, the method has the beneficial effect of obvious cost advantage and environmental-friendly advantage.

Owner:GUIZHOU UNIV

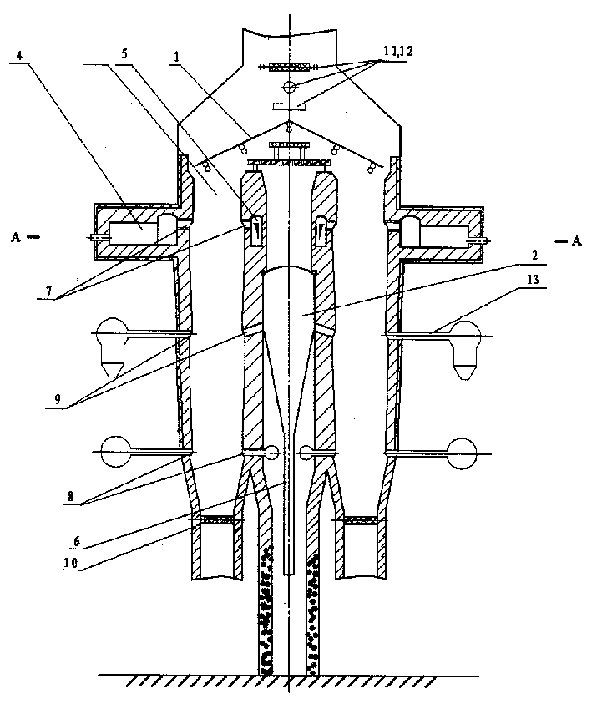

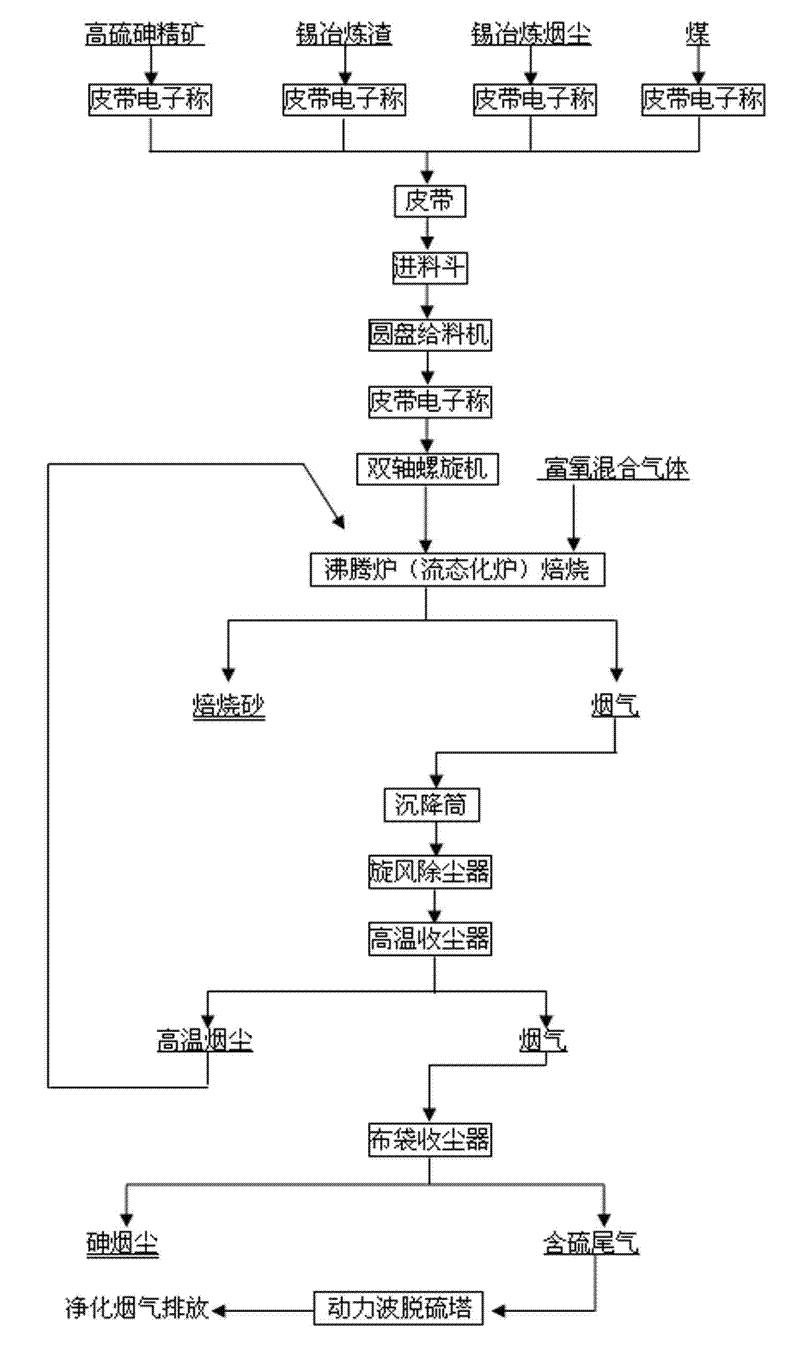

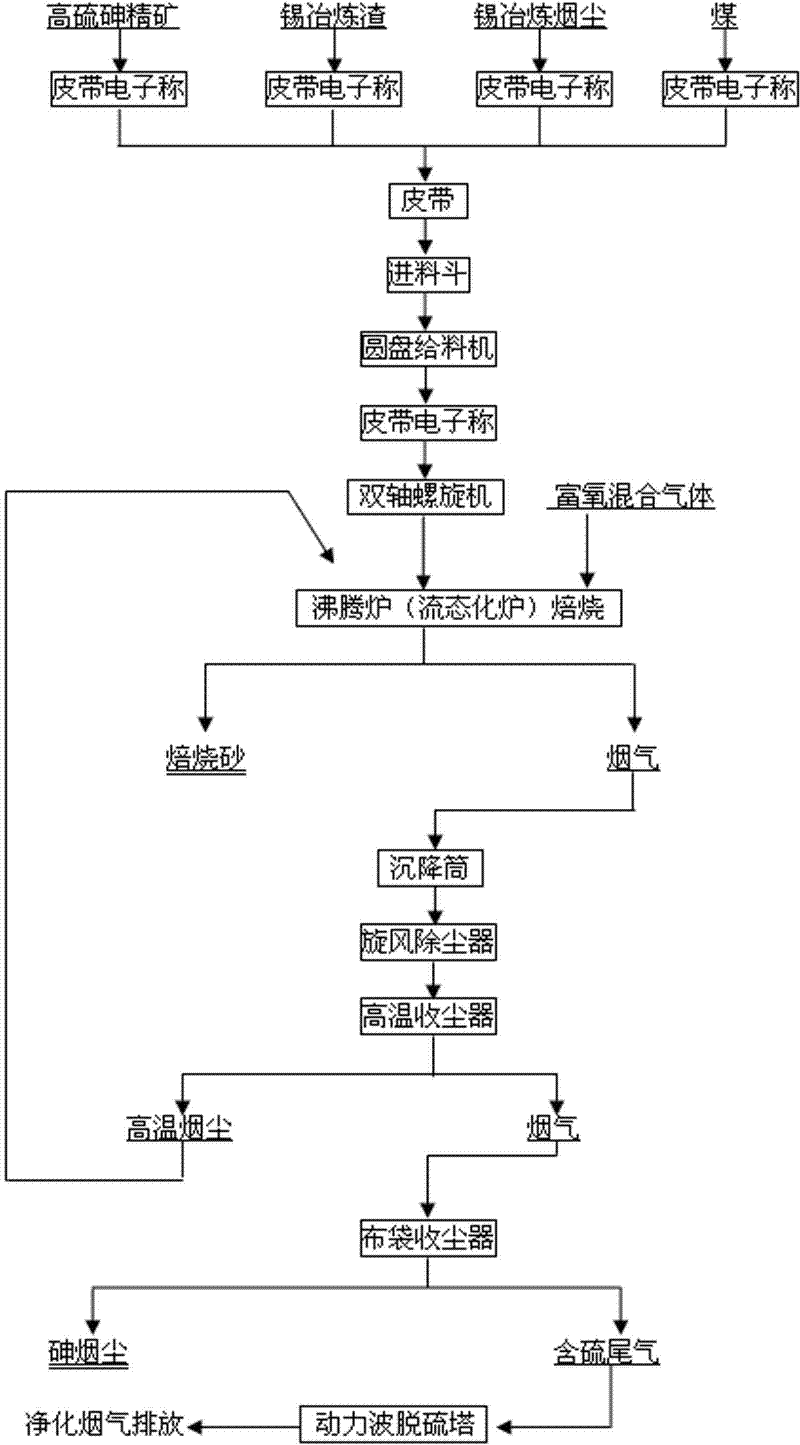

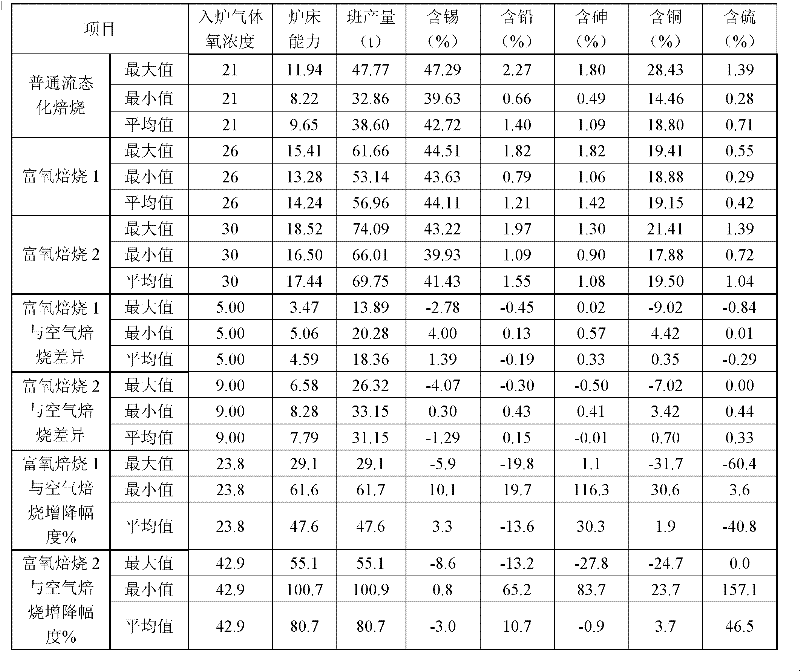

Method for roasting tin-containing high-arsenic and high-sulfur material by fluidized rich oxygen

InactiveCN102230074AIncrease the furnace concentrationReduce the amount of furnaceProcess efficiency improvementExhaust gasArsenic

The invention belongs to the technical field of tin metallurgy, in particular relates to a novel method for roasting a tin-containing high-arsenic and high-sulfur material by fluidized rich oxygen. The method comprises the following steps of: mixing oxygen into a charged gas of a fluidized furnace; controlling the oxygen quantity to reach 22-45 wt% of the total charged gas; carrying out oxygen-enriched fluidized roasting on the material at 600-1000 DEG C; and adding the oxygen in such a way that the quantity of the charged air is gradually reduced and the oxygen quantity is gradually increased so that the total charged gas is invariable and the oxygen concentration satisfies the process parameters while a charging system is started for charging. According to the invention, the arsenic and sulfur removing rate can be effectively increased, the roasting quality can be improved, the smoke gas quantity generated by treatment of the unit material can be reduced, the heat loss can be reduced, the heat utilization rate can be increased, the furnace hearth capacity can be improved without increasing the area of the furnace hearth, the treatment quantity can be increased and the production efficiency can be enhanced; meanwhile, the concentration of SO2 in the smoke gas can be increased so that the problems of low SO2 concentration in the tail gas, unfavorable acid making and environment pollution can be solved to change the harm into the treasure in the tail gas acid making.

Owner:YUNNAN TIN GROUP HLDG

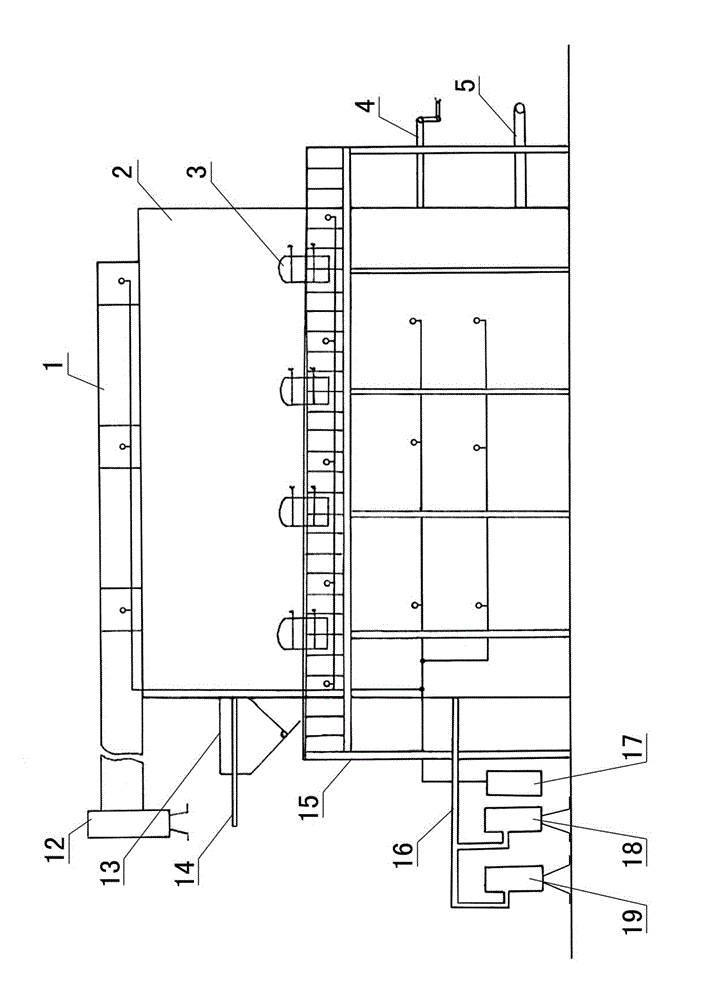

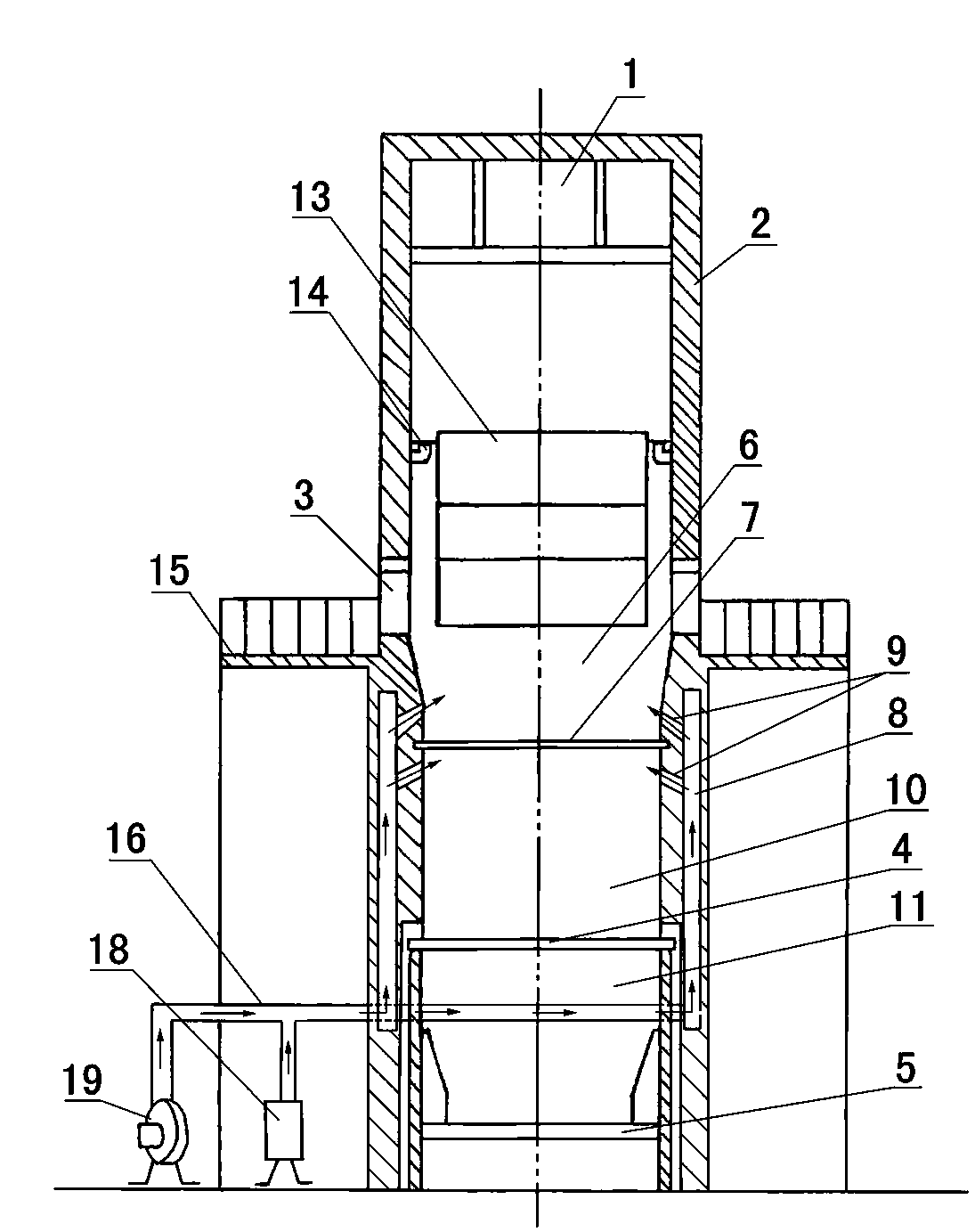

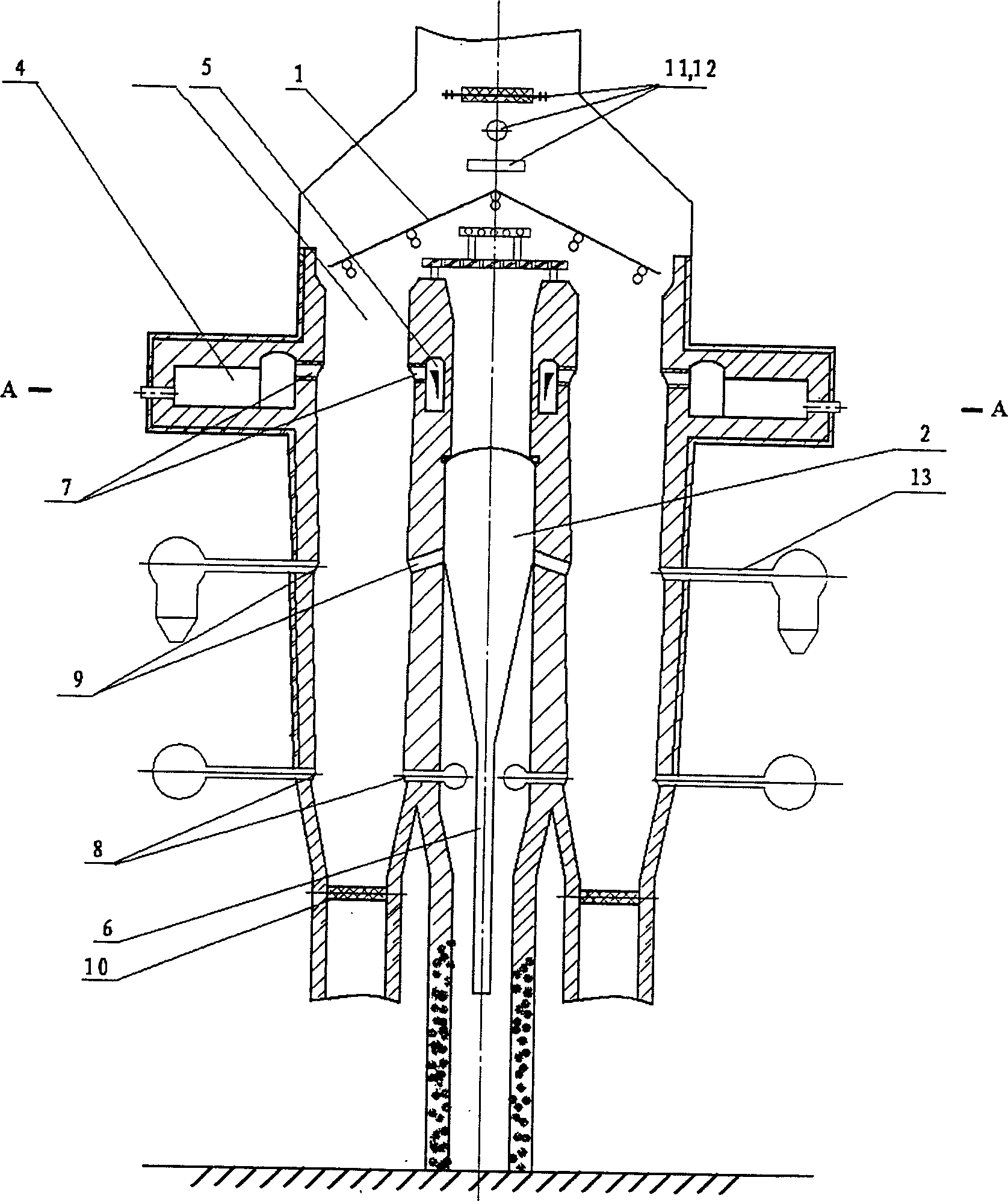

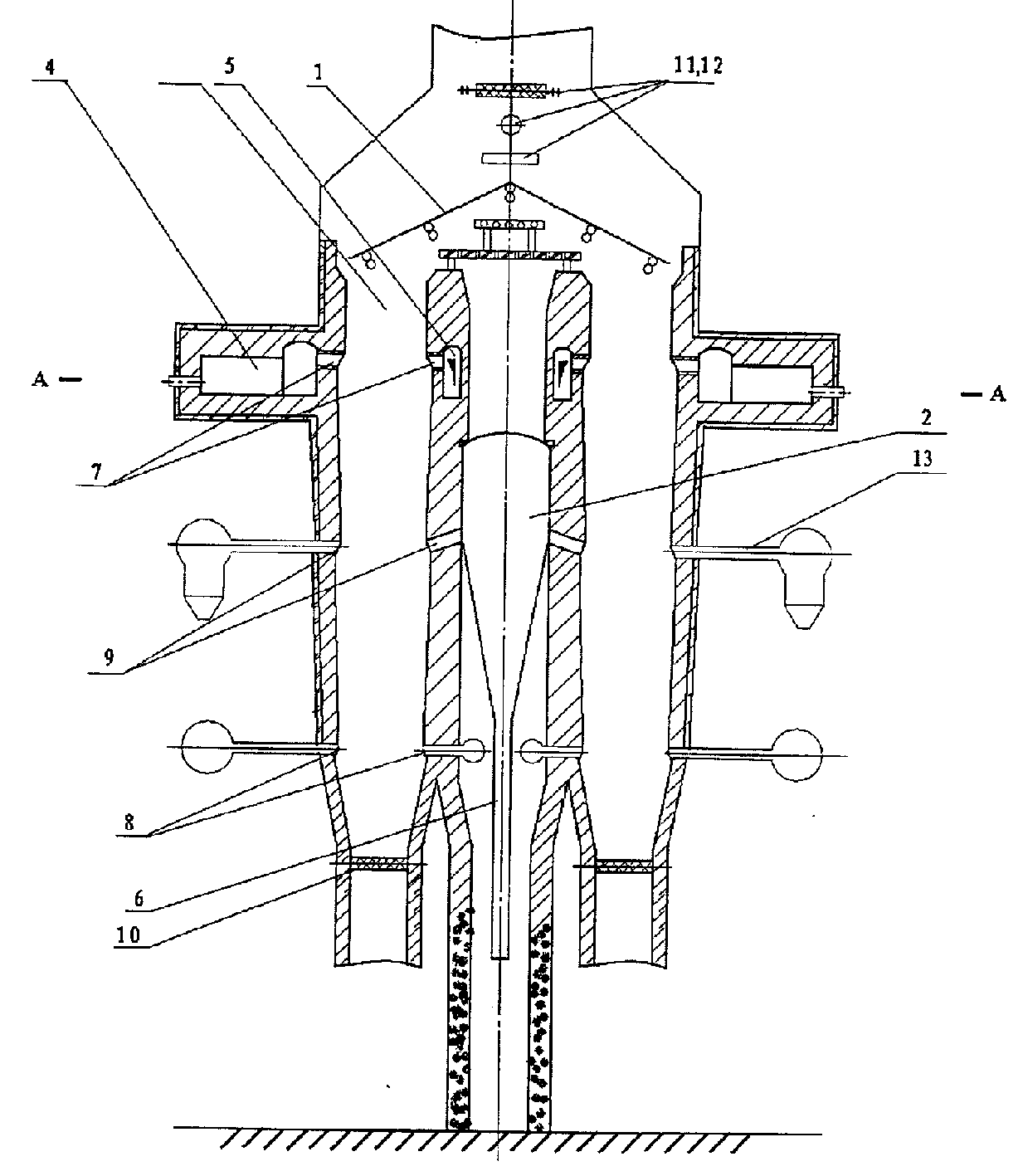

Mechanical navajoite roasting shaft kiln and roasting method

ActiveCN103146910ASolve the costSolve resource problemsVertical furnacesThermal insulationCooling chamber

The invention discloses a mechanical navajoite roasting shaft kiln and a roasting method. The roasting shaft kiln comprises a vertical kiln body and a temperature monitoring system used for monitoring the kiln body, wherein the bottom of the kiln body is provided with a discharging system; an unloader is arranged above the discharging system; a cooling chamber is arranged in the kiln body between the unloader and the discharging system; the kiln body above the unloader is provided with a material distribution machine rail and a material distribution machine moving along the material distribution machine rail; a roasting thermal-insulation chamber is arranged in the kiln body between the material distribution machine and the unloader; an air preheating cavity is arranged in the kiln body wall around the roasting thermal-insulation chamber and the cooling chamber; the air preheating cavity is communicated with the roasting thermal-insulation chamber via a preheated air outlet; and the air preheating cavity is also communicated with an air blower via a blast pipe. The roasting shaft kiln is a mechanical shaft kiln without an external heating source, a navajoite ball is roasted by the self heat of the stone coal navajoite, a great quantity of energy is saved, and the problems of high production cost, big resource waste and big tail gas discharge of the shaft kiln with the external heat source are solved.

Owner:LAOHEKOU LVHUA ENVIRONMENTAL PROTECTION TECH

Sintered light-weight environment-friendly brick produced from printing and dyeing sludge and manufacture method thereof

Owner:清远绿由环保科技有限公司

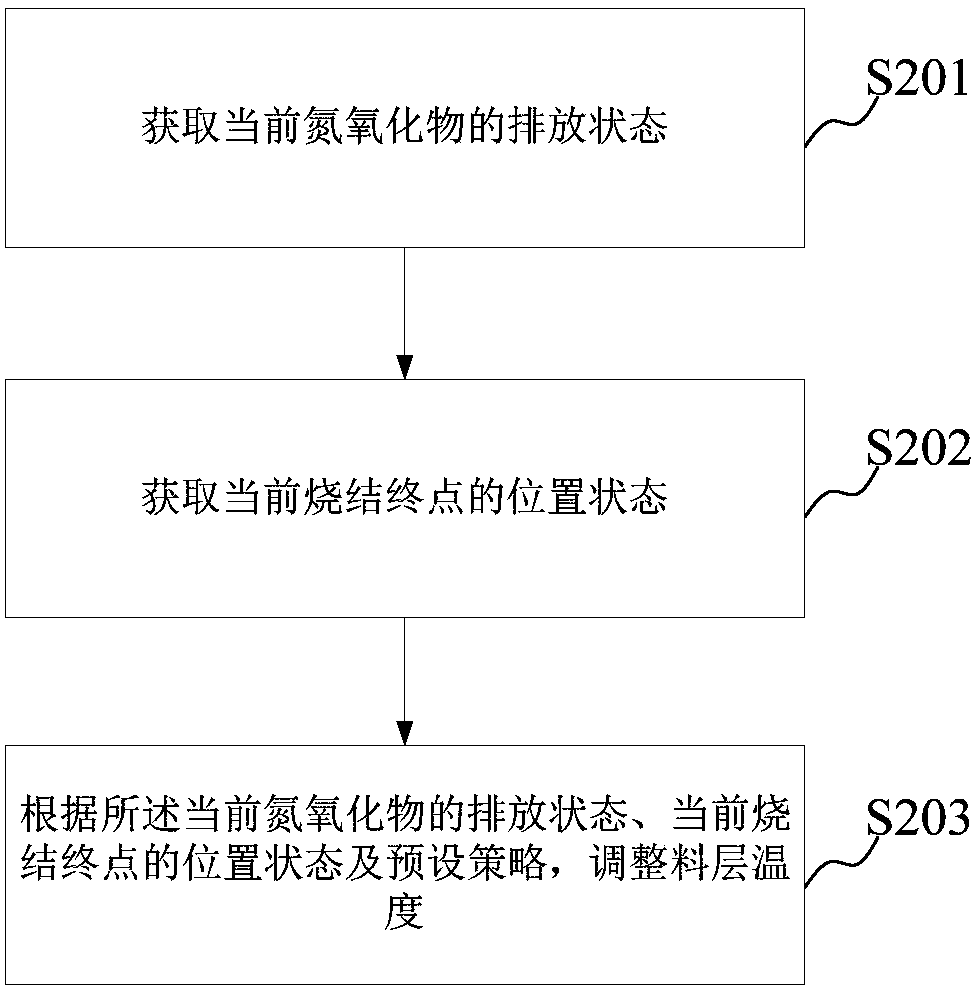

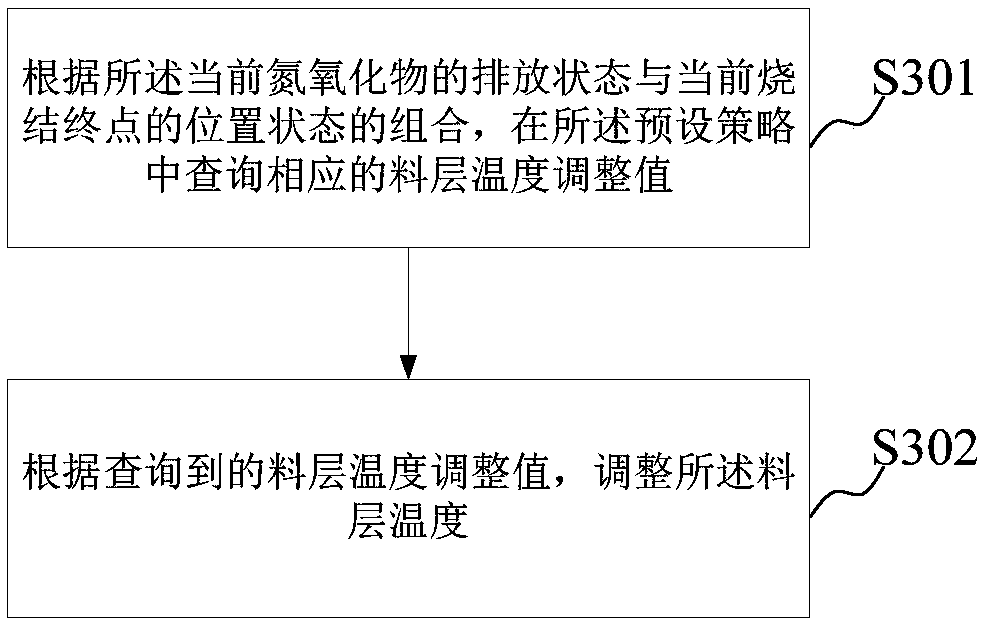

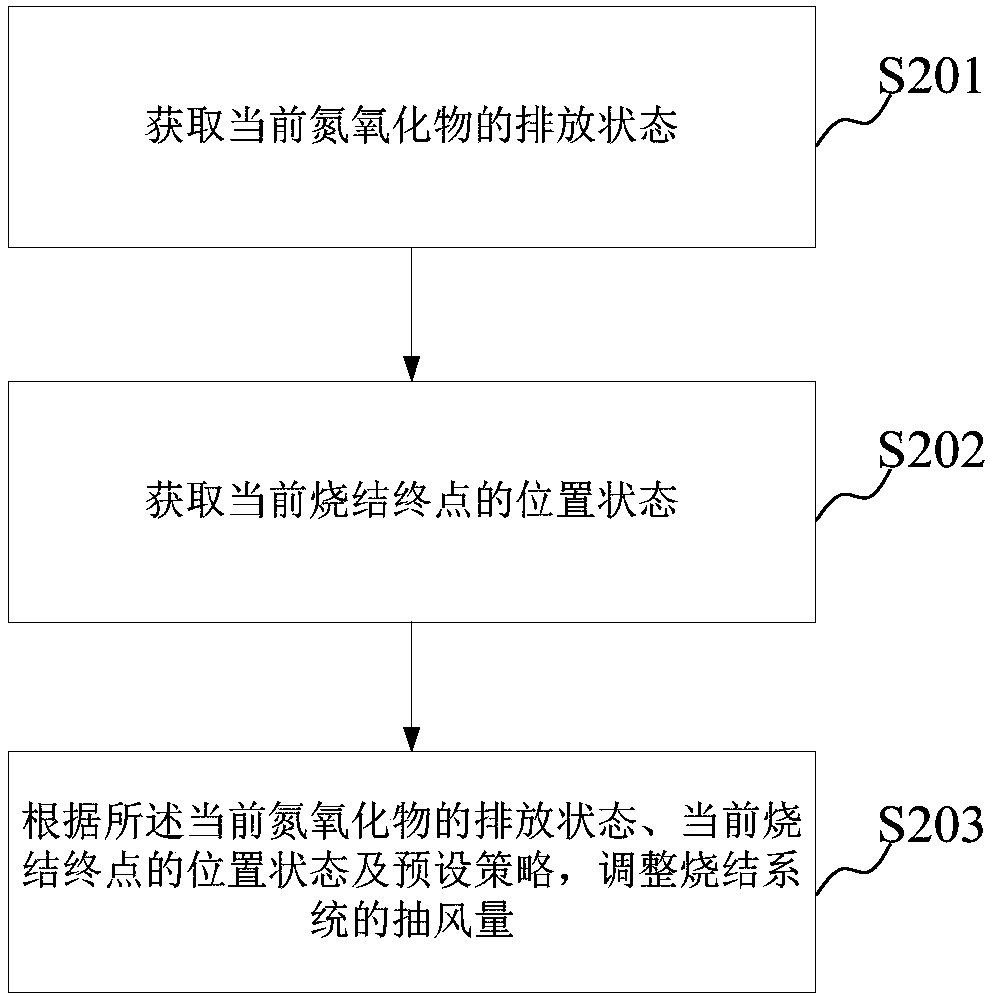

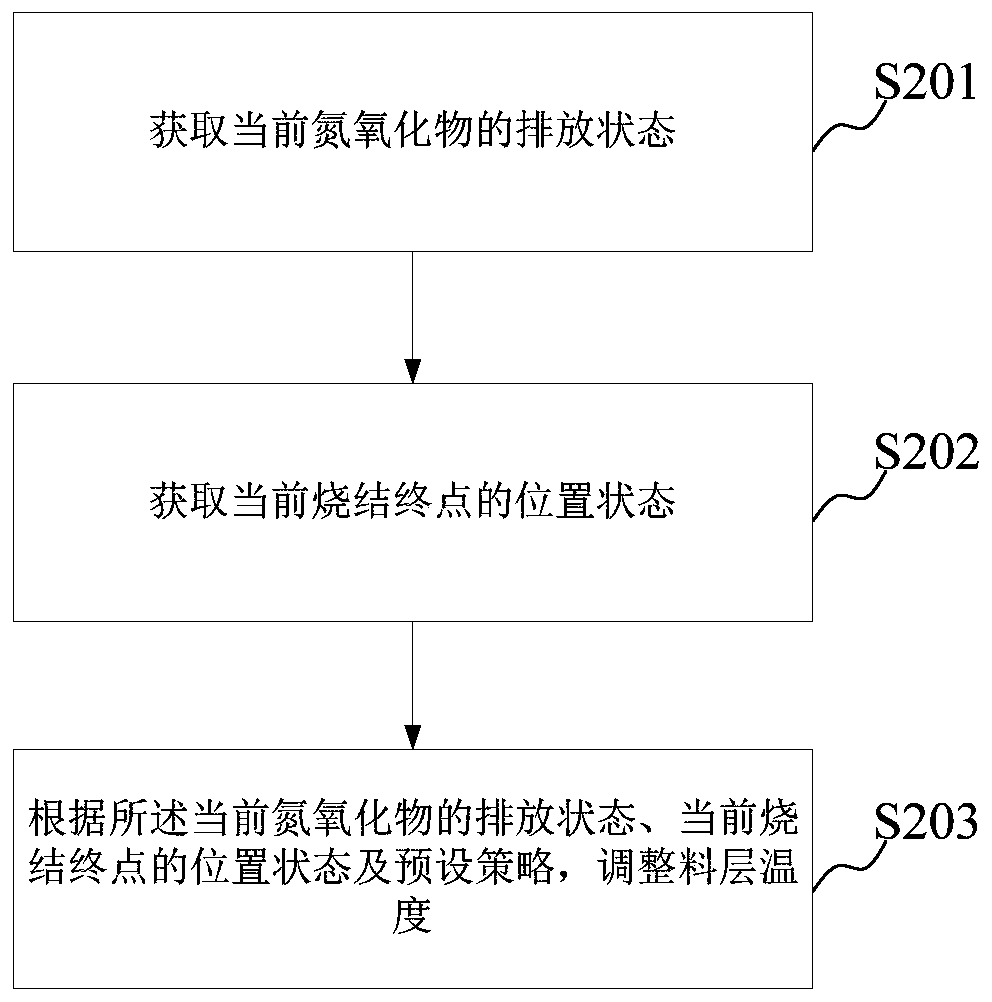

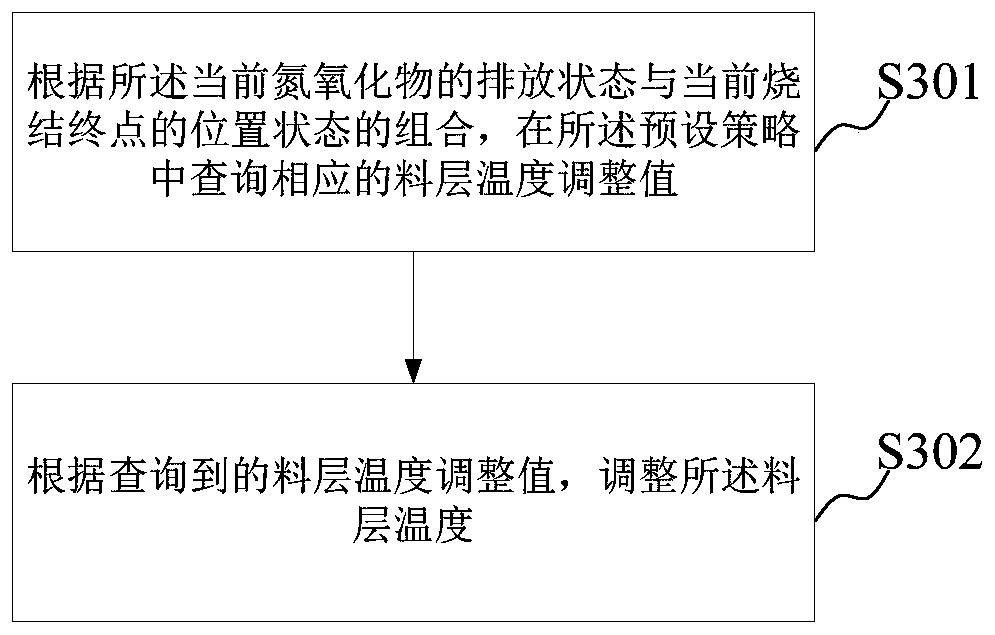

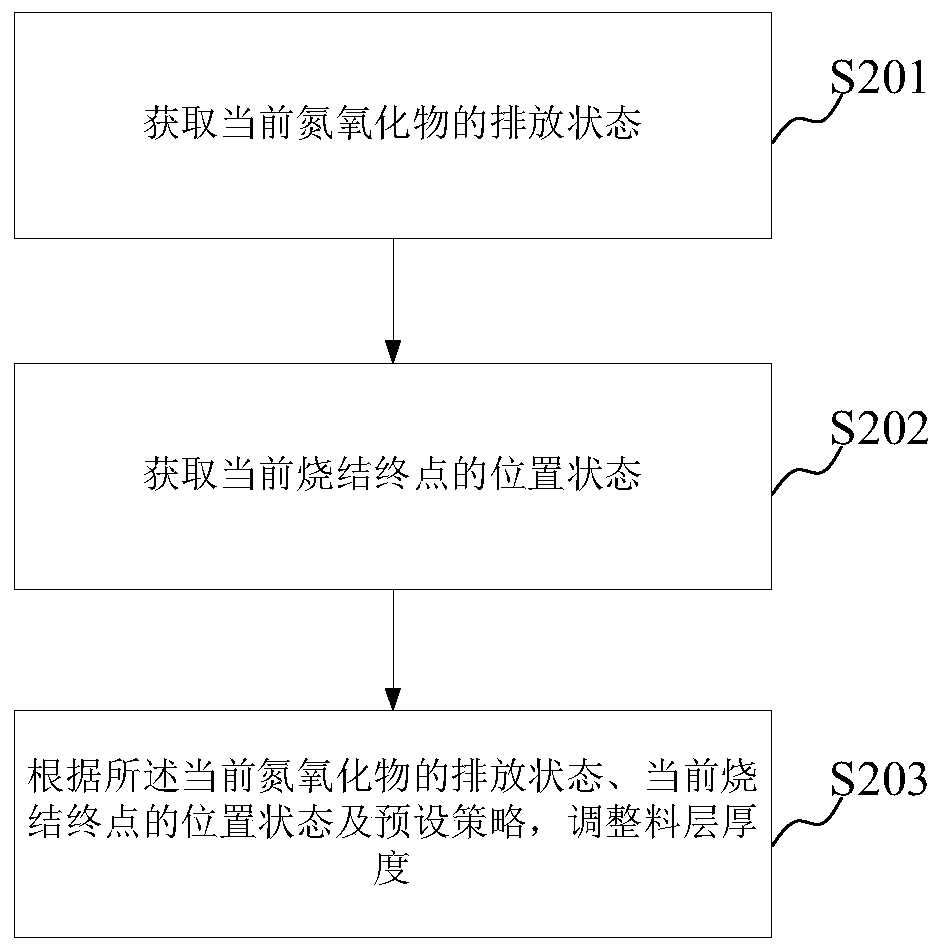

Nitrogen oxide emission control method and device

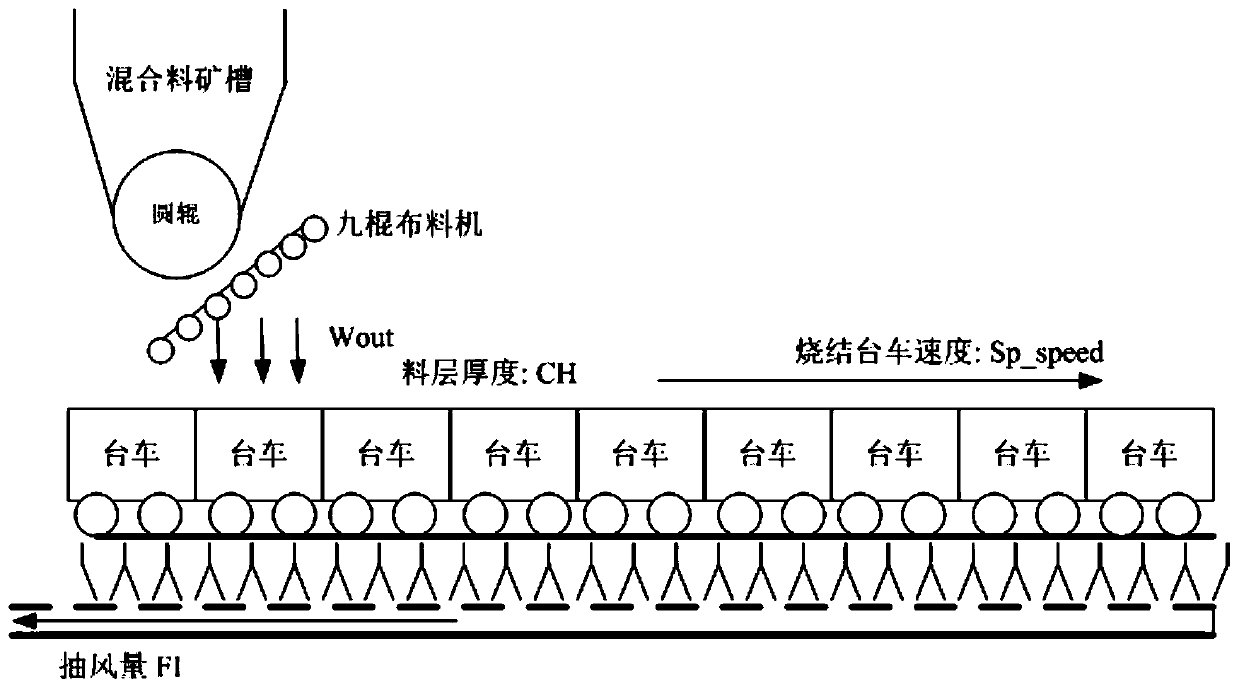

ActiveCN108267024AReduce thicknessReduce spawn rateControl devices for furnacesNitrogen oxidesMetallurgy

The embodiment of the invention provides a nitrogen oxide emission control method and device. The method comprises the steps of obtaining the current nitrogen oxide emission state; obtaining the current positional state of a sintering final point; and according to the current nitrogen oxide emission state, the current positional state of the sintering final point and a preset strategy, adjusting the temperature of a material layer. According to the nitrogen oxide emission control method and device, the temperature of the material layer is adjusted according to the current nitrogen oxide emission state, the current positional state of the sintering final point and the preset strategy, so that on the premise that it is guaranteed that the sintering final point is at the reasonable position,the temperature of the material layer is properly raised, and the sintering speed, namely the vertical sintering speed, achieved in the sintering process can be increased; thus, the thickness of a burning belt is reduced; furthermore, the generation probability of nitrogen oxide is lowered; the cost is low, and in addition, physical properties of sintered ore are not affected; and quality of the sintered ore can be guaranteed.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

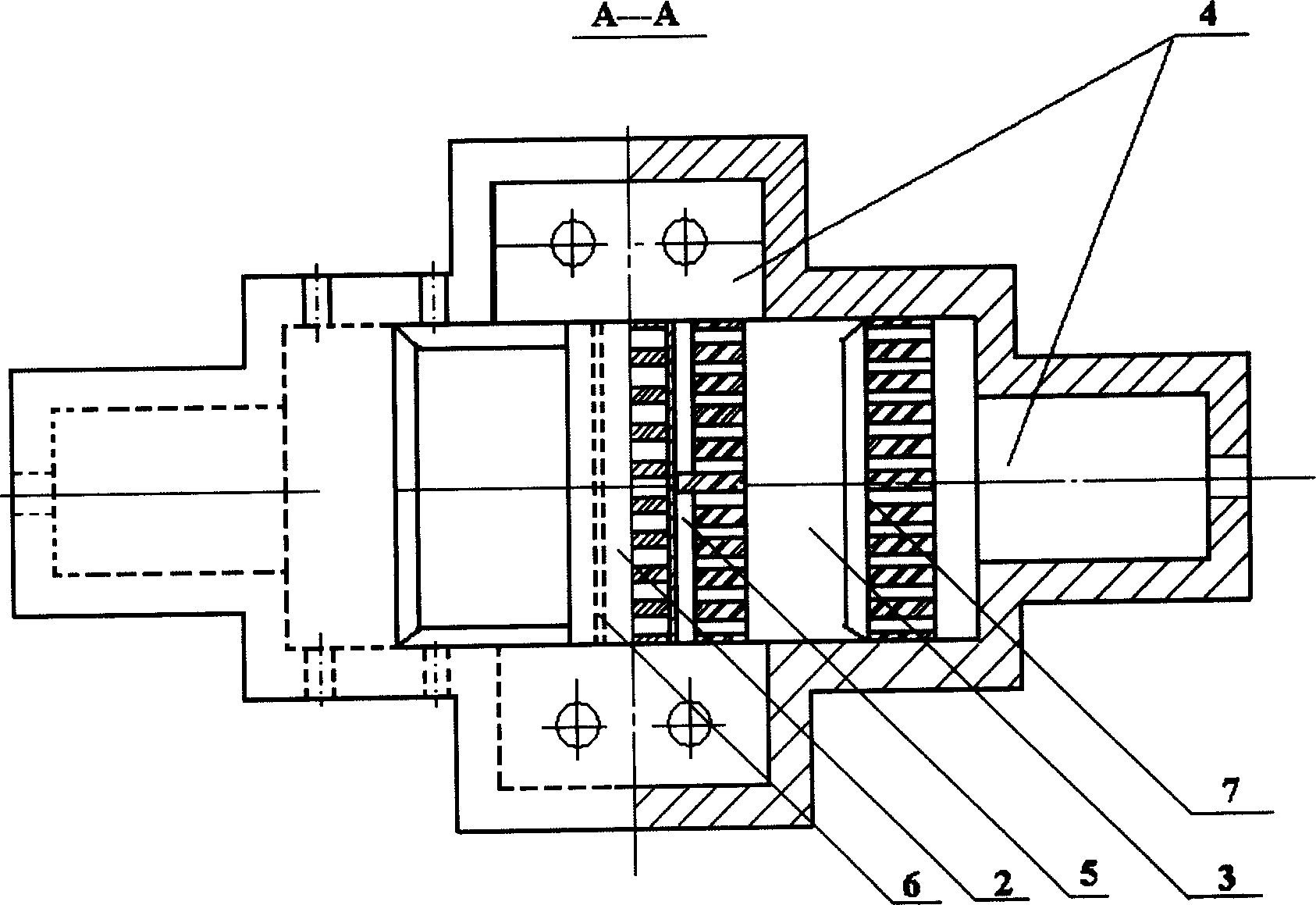

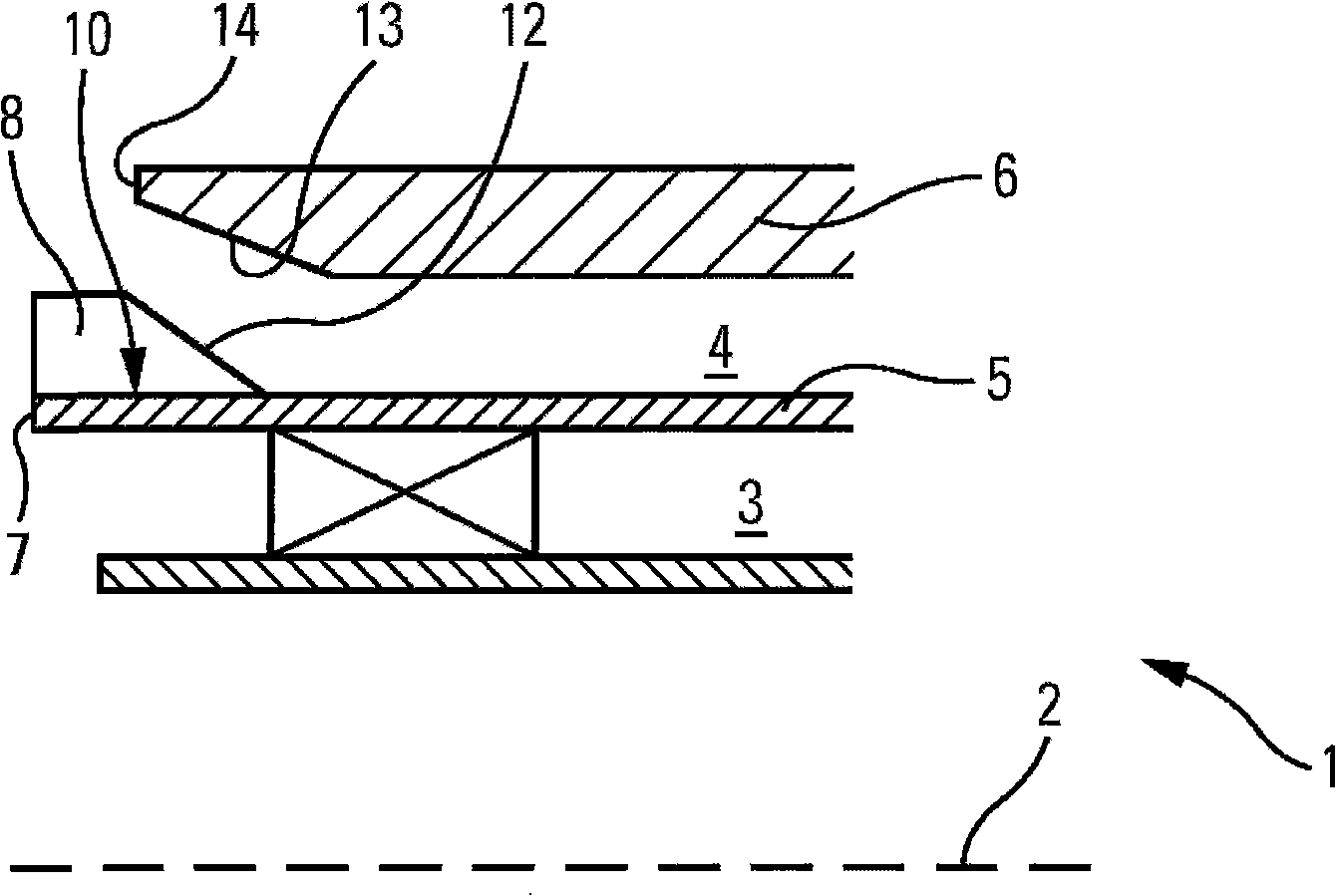

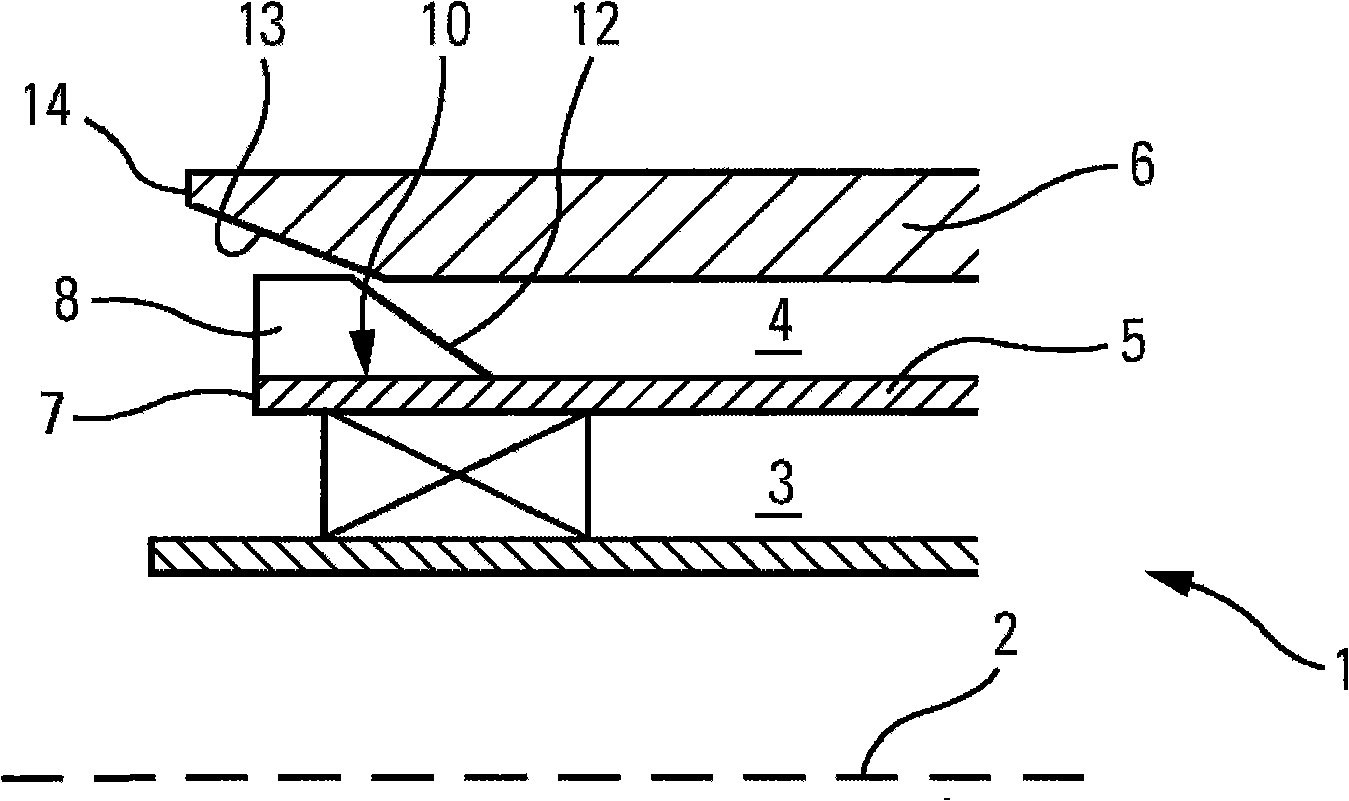

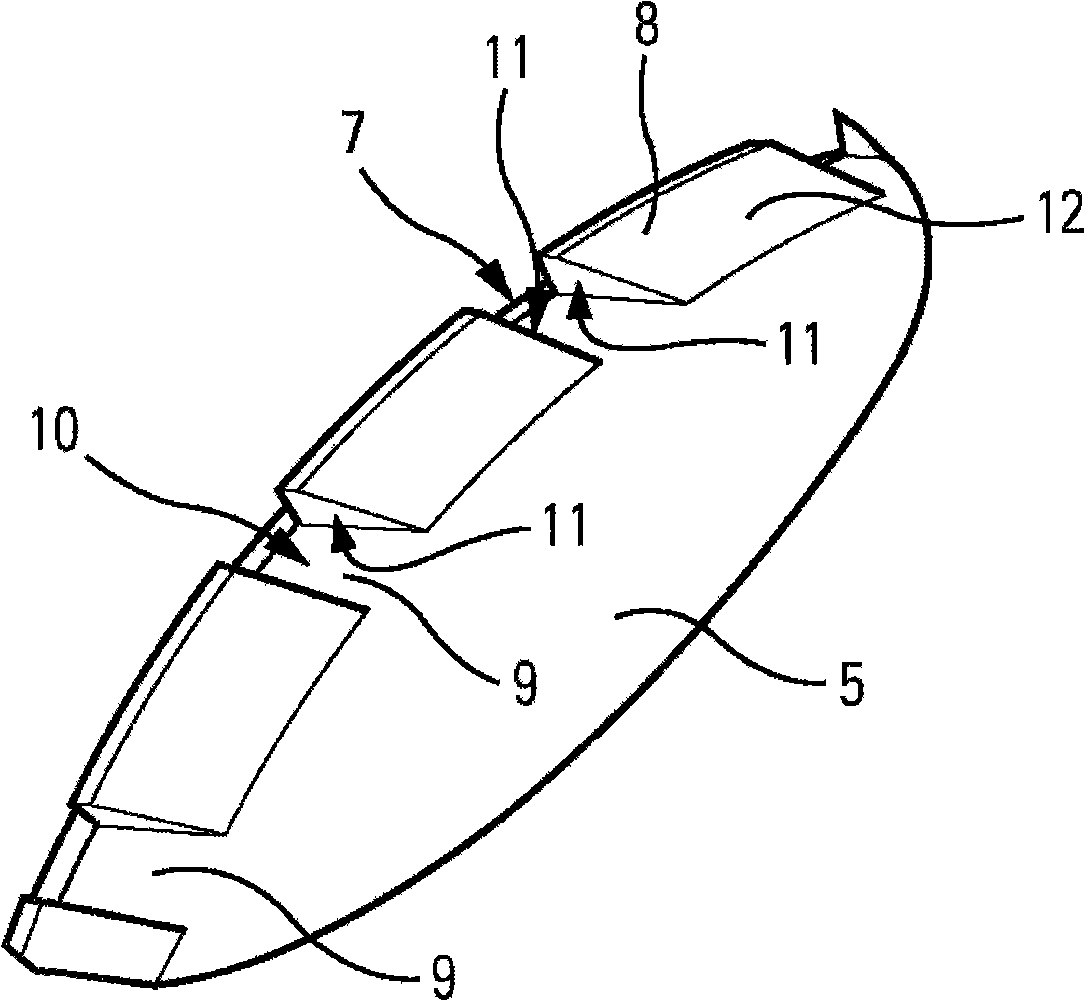

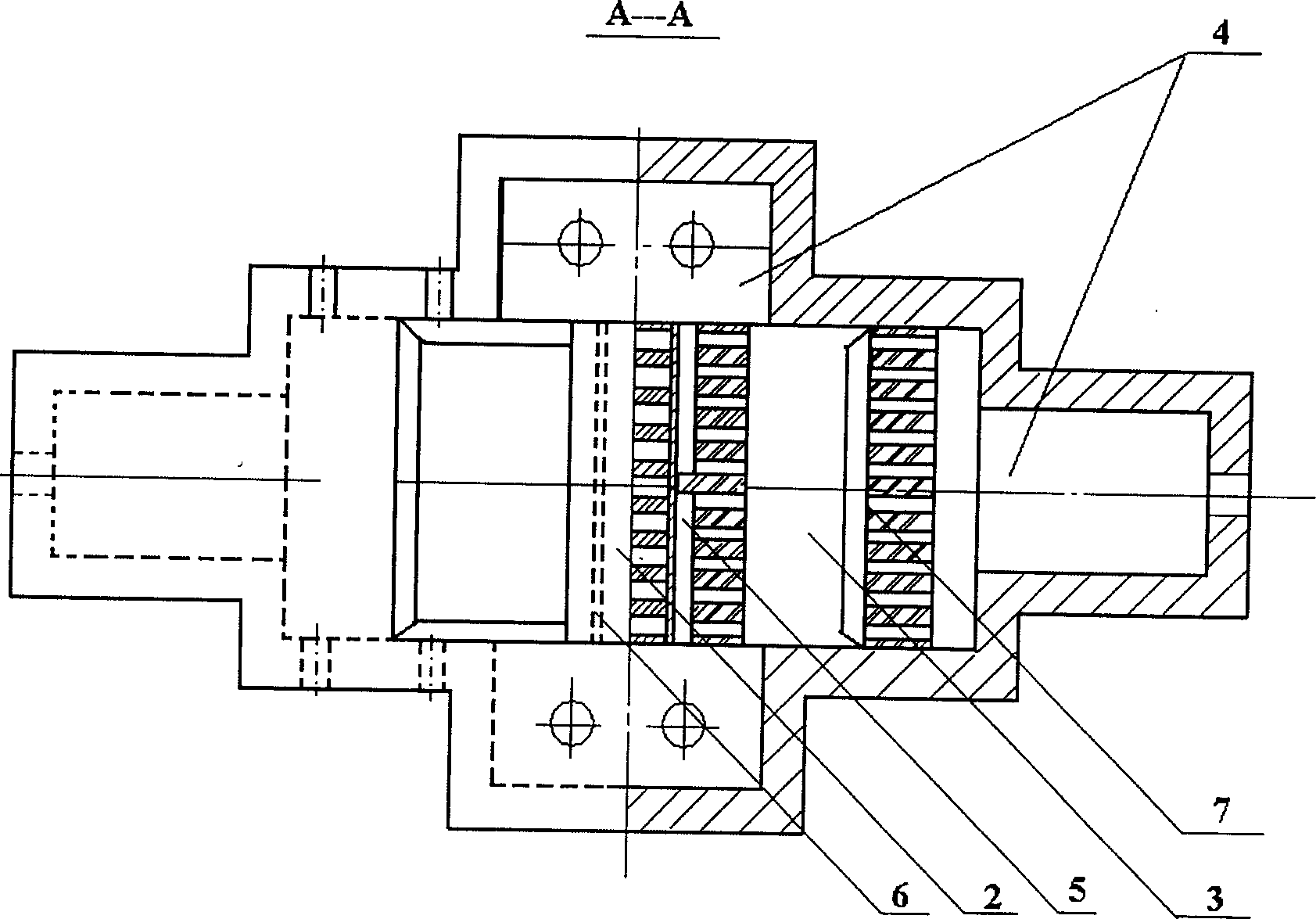

Burner

InactiveCN101349426ASpeed up roastingReduce rateGaseous fuel burnerCombustion apparatusEngineeringFlange

The invention relates to a burner (1) which comprises an air supply annular tube (4) limited by two coaxial conduits (5, 6) that can move relative to each other along the axis between the open position and the close position. The conduit (5) has an annular flange (8) comprising an axial groove. According to the invention, the flange (8) is disposed on the downstream end (7) of the conduit (5); the second conduit (6) comprises a closure part (13). While the conduits (5, 6) is on the open position, the distance between closure part (13) and the flange (8) is large enough for a great deal of air to pass through; while the conduits (5, 6) is on the close position, the distance is almost zero to make all the air pass through the groove.

Owner:FIVES PILLARD

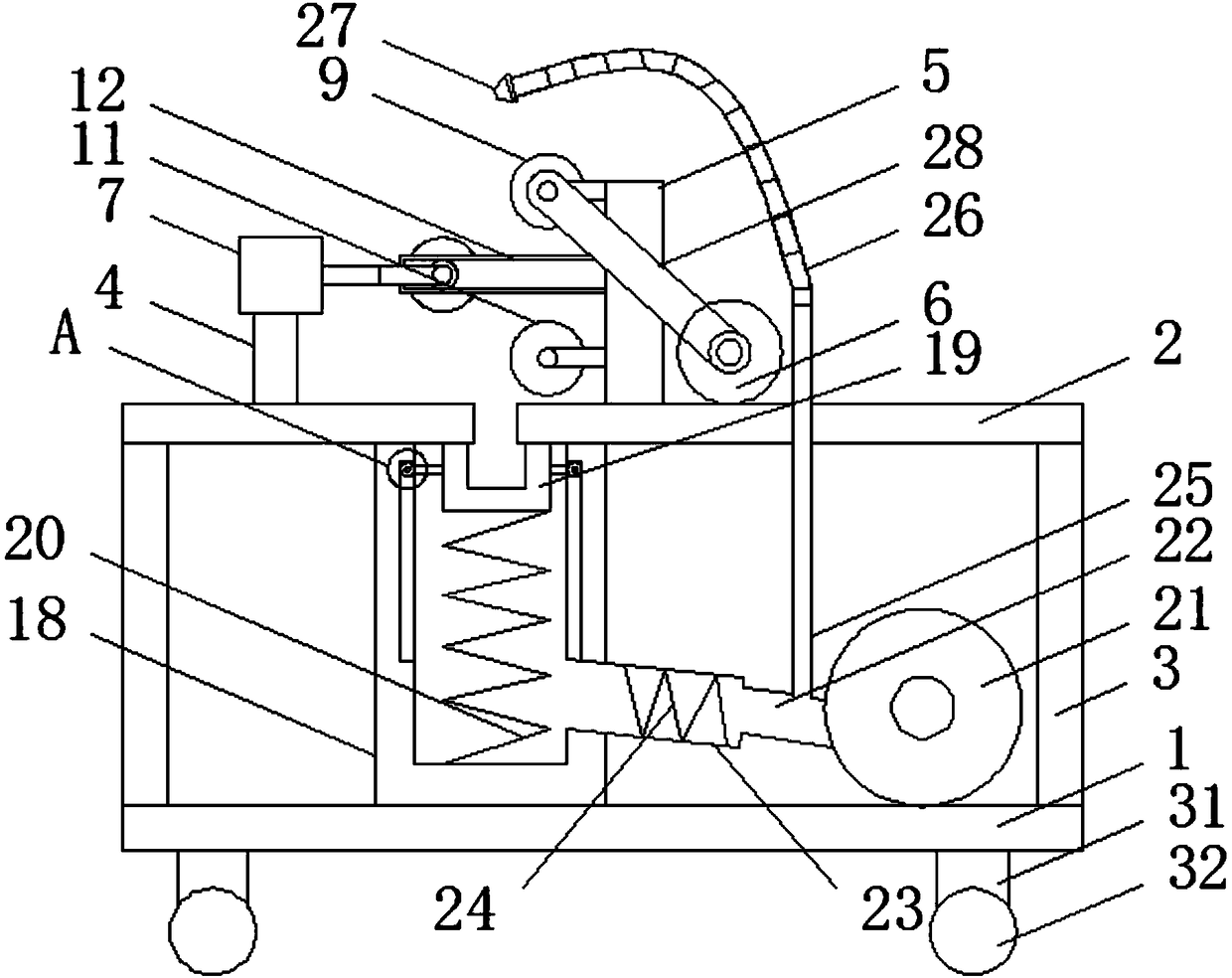

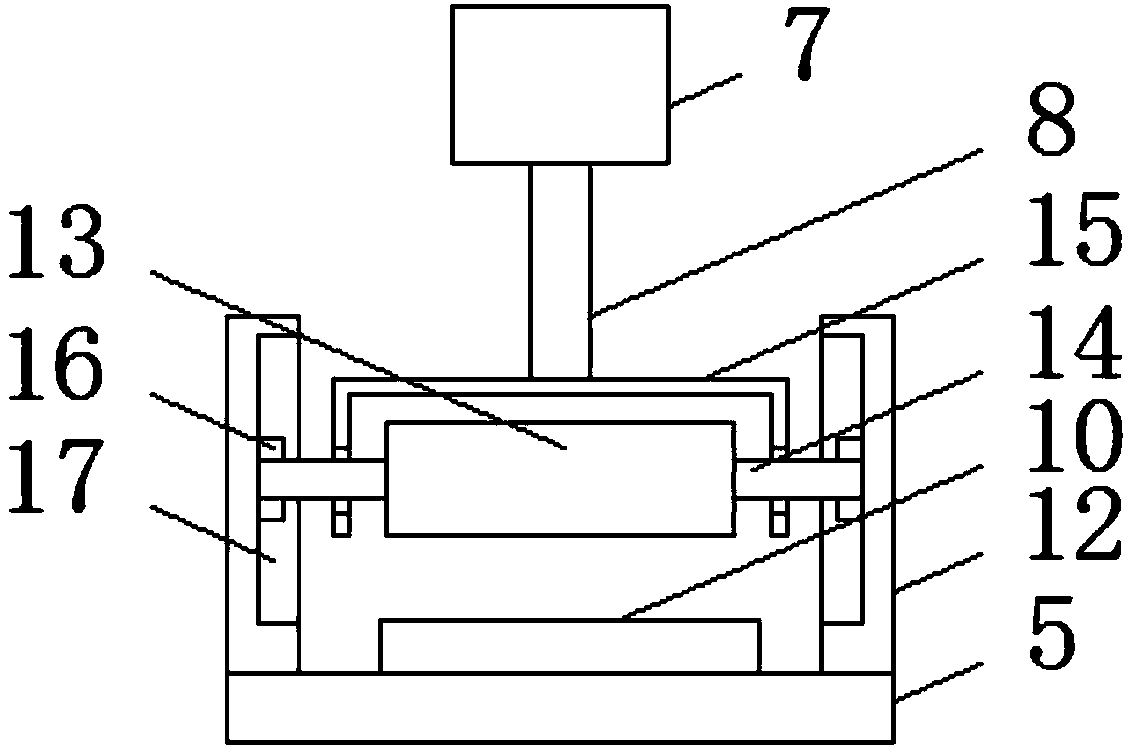

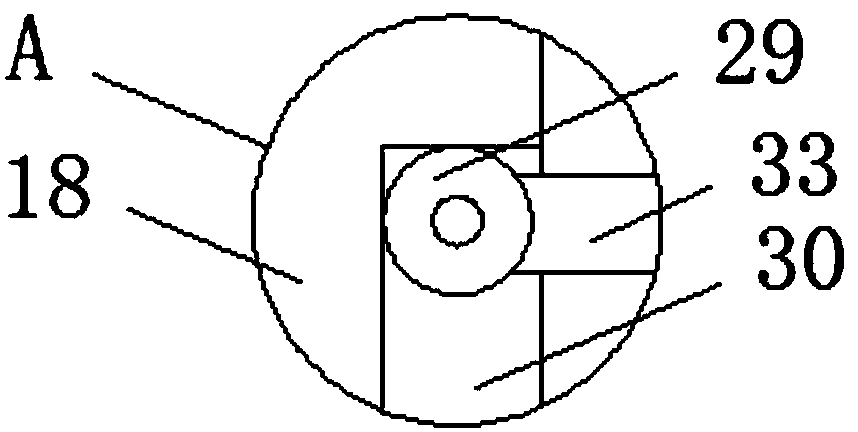

High-reliability bending device for plastic processing and bending method

PendingCN108340563AReduce baking timeShorten the timeHydraulic cylinderElectrical resistance and conductance

The invention discloses a high-reliability bending device for plastic processing, and belongs to the field of bending devices. The high-reliability bending device for plastic processing comprises a base and a workbench. A hydraulic cylinder is arranged at the top of the supporting base. A heating resistance wire is arranged in an inner cavity of a heating tube. The right side of the heating tube is connected with a three-way pipe. The heating resistance wire is used for heating air in the heating tube. Hot air then enters an inner cavity of a preheating chamber. A plastic product is preheatedin advance and then is softened through baking by a baking lamp, the bake-softening speed is increased, and the baking time of the baking lamp is shortened; the hydraulic cylinder drives a telescopicrod, the telescopic rod then pushes a second driven wheel, the moving distance of the second driven wheel is determined according to a calibrated scale, and thus, the degree of bending of the plasticproduct is changed by changing the moving distance of the second driven wheel; and an air blower enters the annular hose through a three-way joint, the direction of an air nozzle can be adjusted freely through the annular hose, air is blown towards the bake-softened and bent plastic product through the air nozzle, and thus cooling and shaping of the plastic product are accelerated.

Owner:杨浩

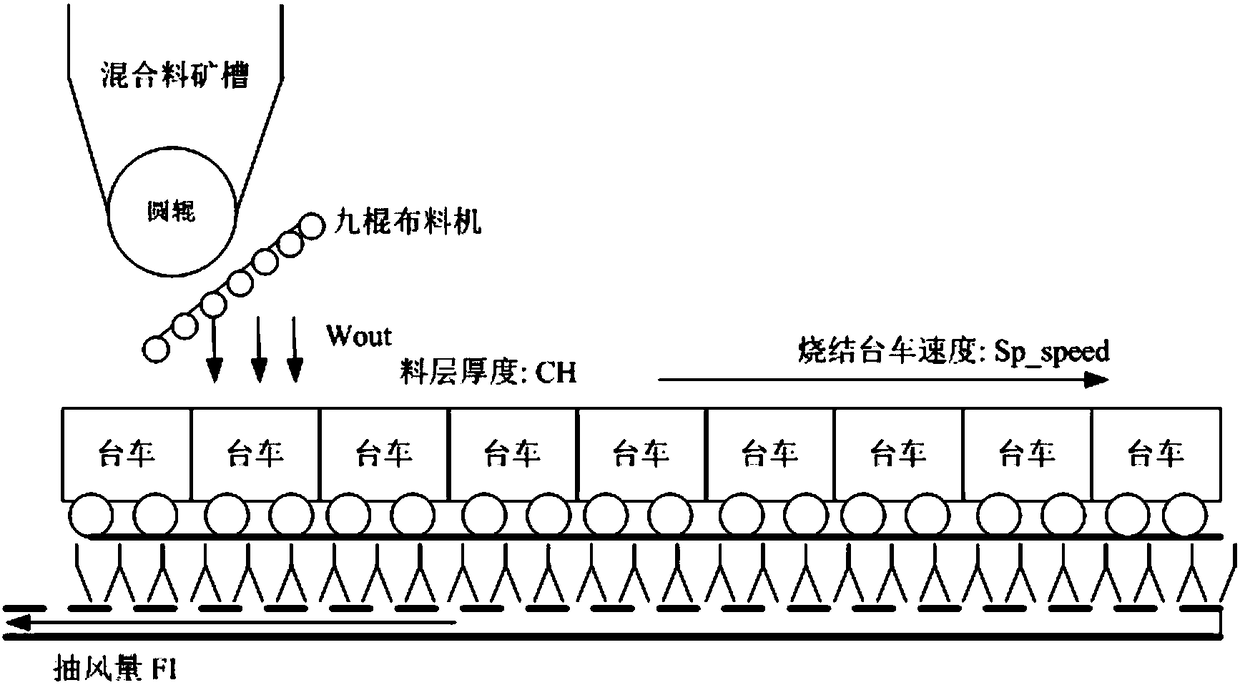

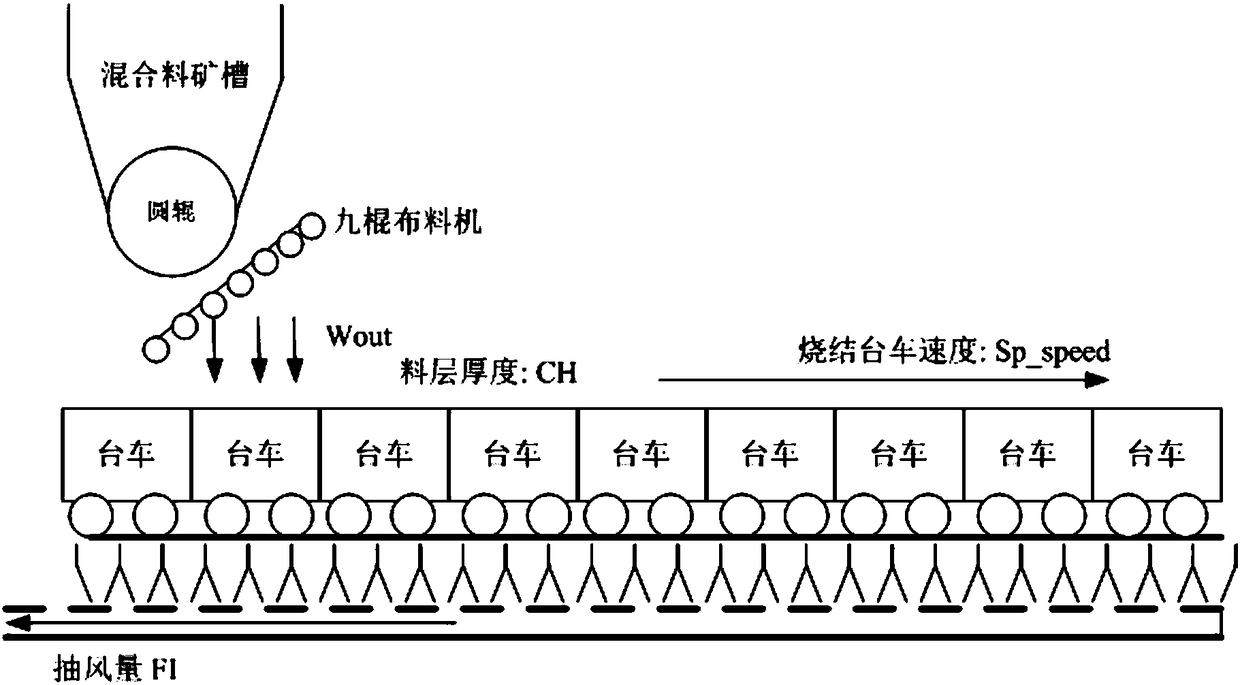

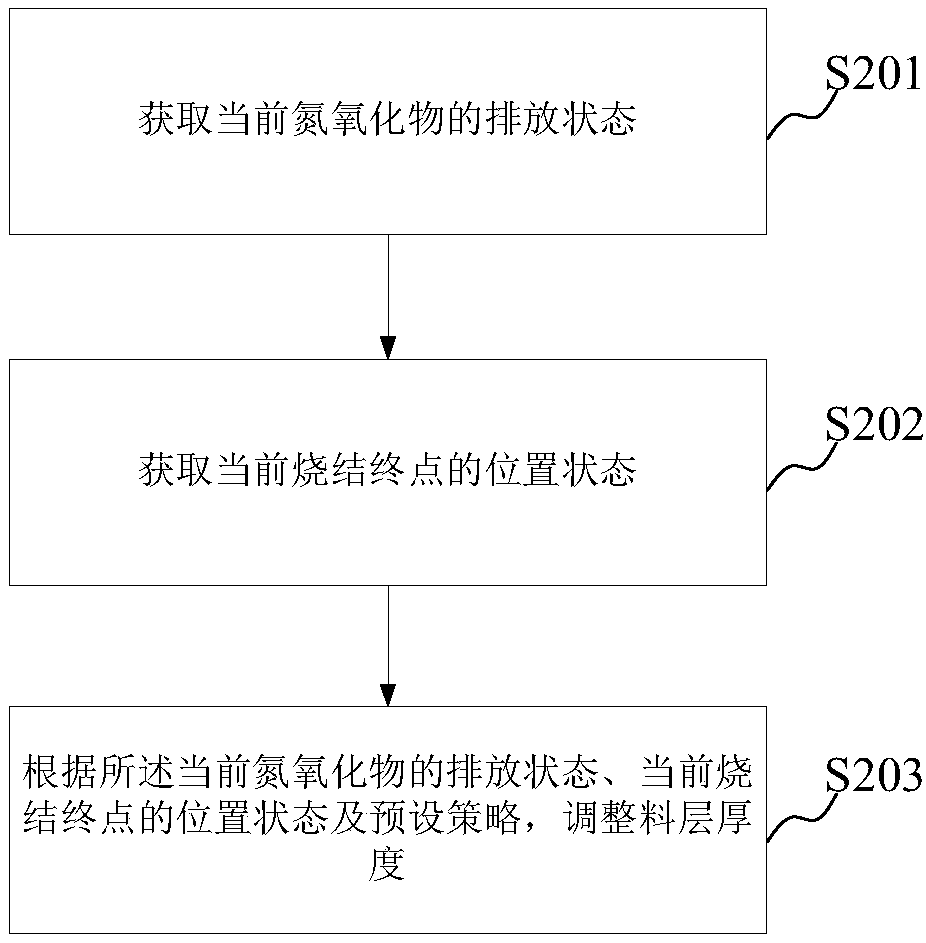

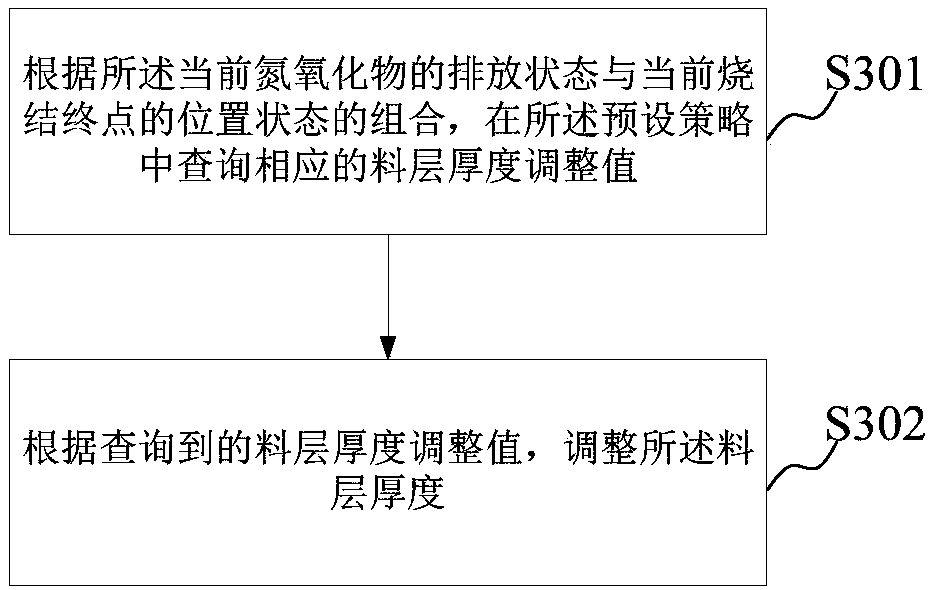

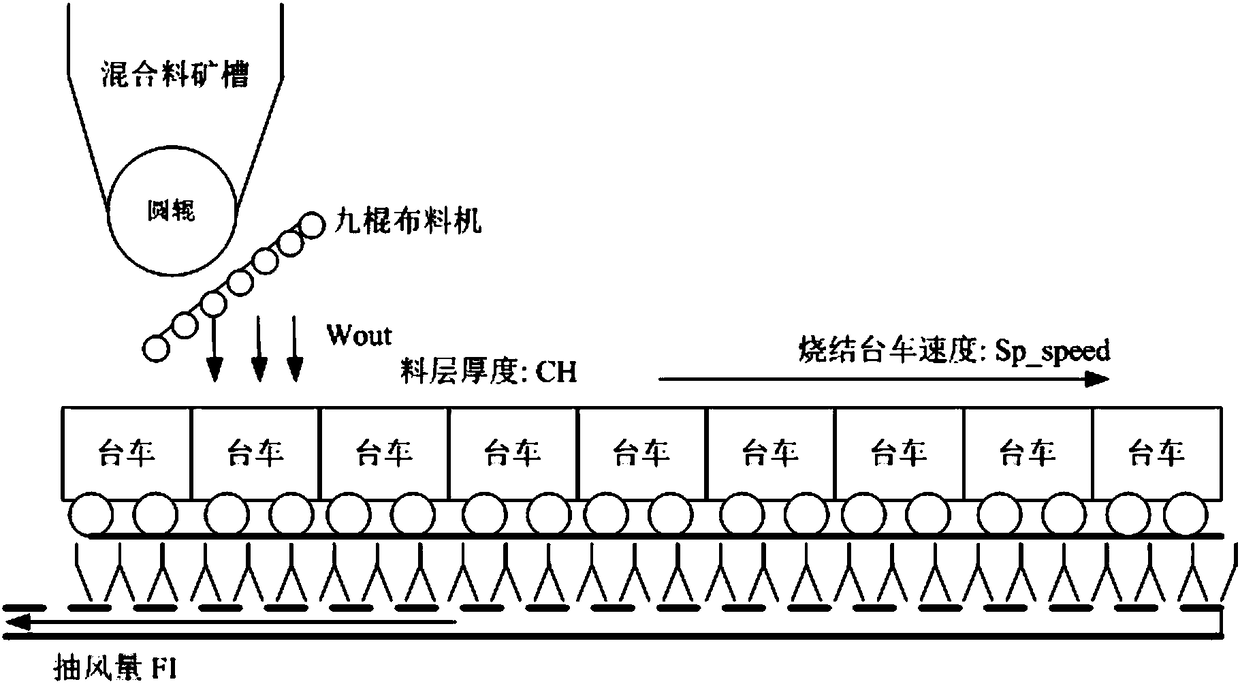

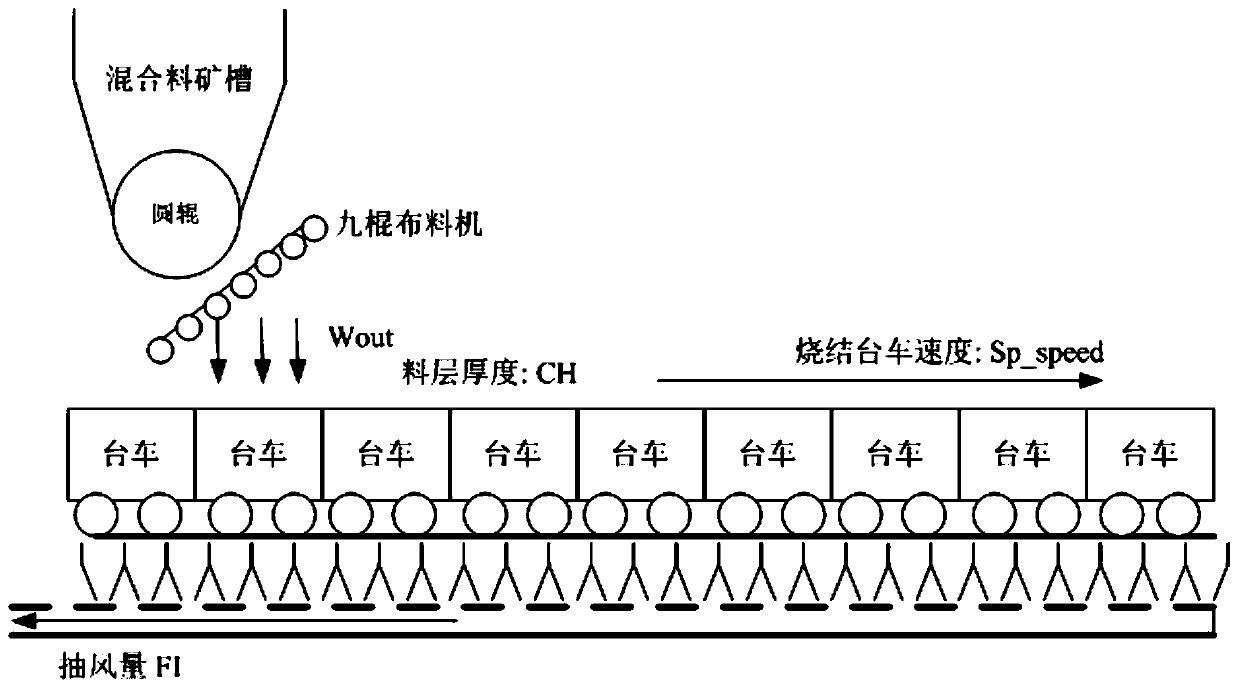

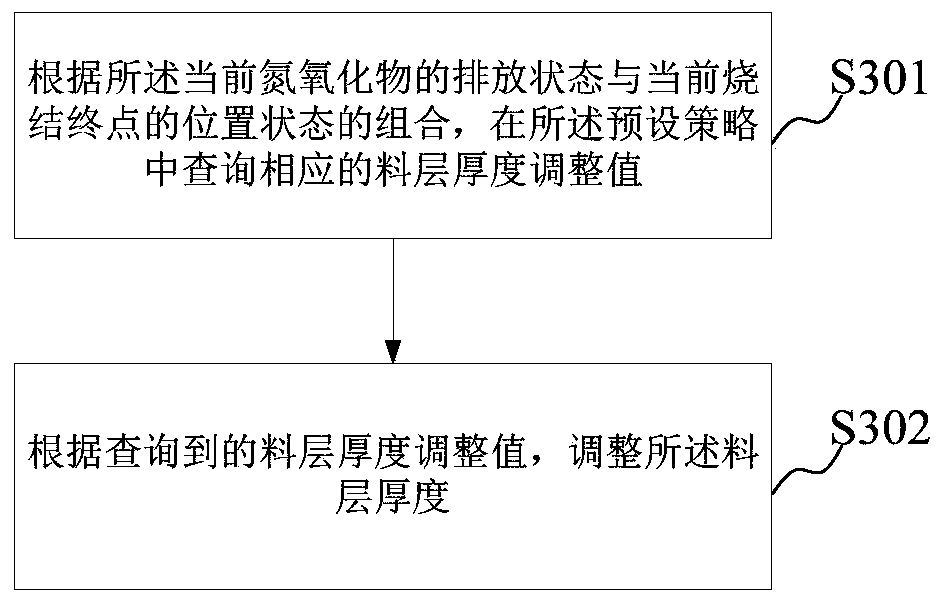

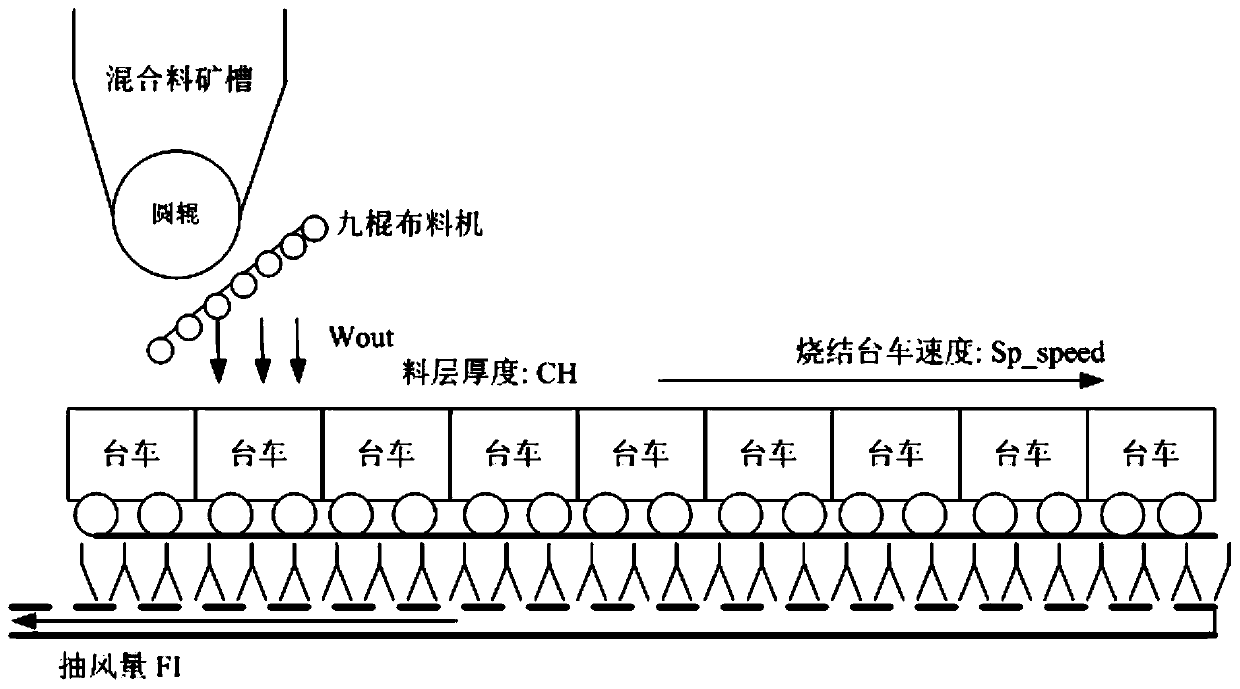

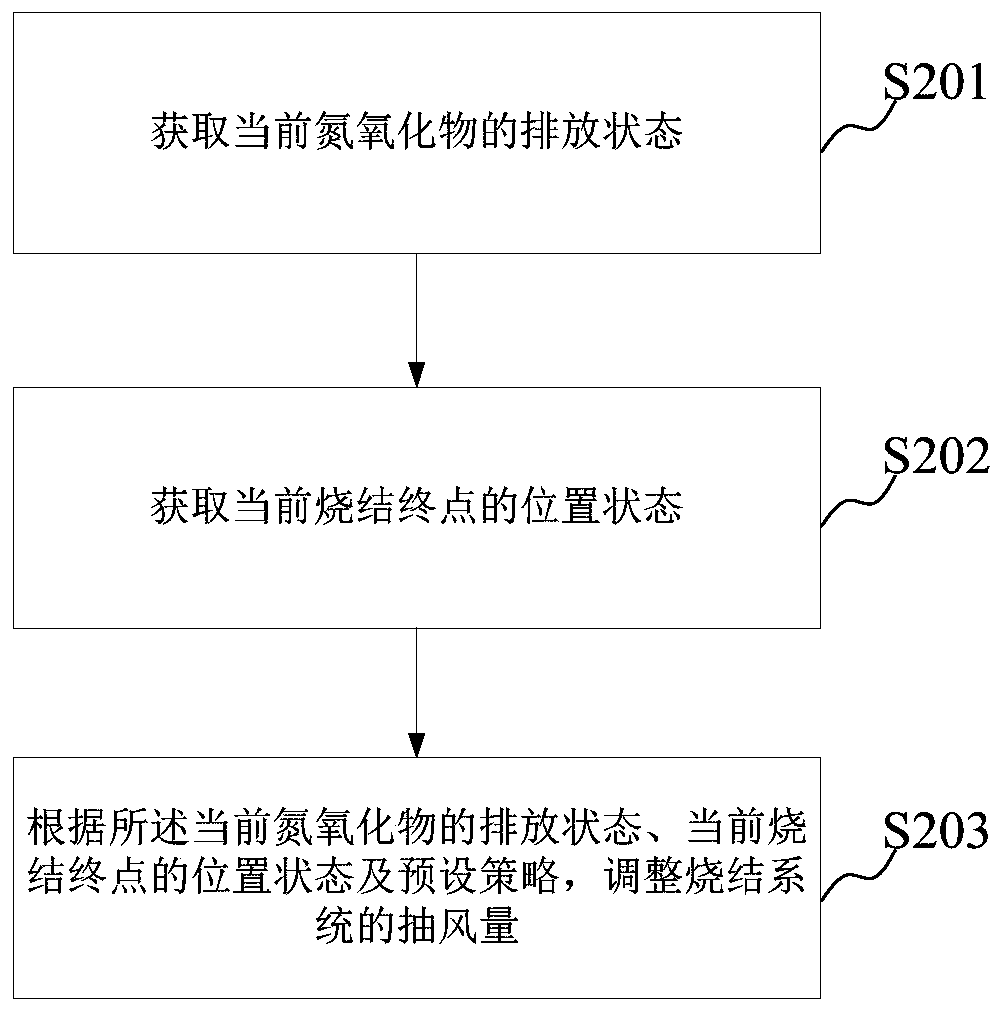

Nitrogen oxide emission control method and device

ActiveCN108267008AReduce thicknessReduce spawn rateFurnace typesControl devices for furnacesCombustionNitrogen oxides

The embodiment of the invention provides a nitrogen oxide emission control method and device. The method comprises the following steps that the emission state of current nitrogen oxide is acquired; the position state of a current sintering end point is obtained; and the thickness of a material layer is adjusted according to the emission state of the current nitrogen oxide, the position state of the current sintering end point and a preset strategy. In the embodiment of the nitrogen oxide emission control method and device, according to the emission state of the current nitrogen oxide, the position state of the current sintering end point and the preset strategy, the thickness of the material layer is adjusted, under the premise that the sintering end point is ensured to be at a reasonableposition, the thickness of the material layer is properly reduced so as to improve air permeability of the material layer, the roasting speed (namely the vertical sintering speed) of the sintering process can be increased, so that the thickness of a combustion zone is reduced, and therefore the probability of nitrogen oxide generation is reduced, cost is low, the physical property of sintered oreis not influenced at the same time, and the quality of the sintered ore can be guaranteed.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Mechanical navajoite roasting shaft kiln and roasting method

ActiveCN103146910BSolve environmental problemsSolve resource problemsVertical furnacesThermal insulationCooling chamber

The invention discloses a mechanical navajoite roasting shaft kiln and a roasting method. The roasting shaft kiln comprises a vertical kiln body and a temperature monitoring system used for monitoring the kiln body, wherein the bottom of the kiln body is provided with a discharging system; an unloader is arranged above the discharging system; a cooling chamber is arranged in the kiln body between the unloader and the discharging system; the kiln body above the unloader is provided with a material distribution machine rail and a material distribution machine moving along the material distribution machine rail; a roasting thermal-insulation chamber is arranged in the kiln body between the material distribution machine and the unloader; an air preheating cavity is arranged in the kiln body wall around the roasting thermal-insulation chamber and the cooling chamber; the air preheating cavity is communicated with the roasting thermal-insulation chamber via a preheated air outlet; and the air preheating cavity is also communicated with an air blower via a blast pipe. The roasting shaft kiln is a mechanical shaft kiln without an external heating source, a navajoite ball is roasted by the self heat of the stone coal navajoite, a great quantity of energy is saved, and the problems of high production cost, big resource waste and big tail gas discharge of the shaft kiln with the external heat source are solved.

Owner:湖北汇锂新能源科技有限公司

Sintered light-weight environment-friendly brick produced from electroplating sludge and manufacture method thereof

The invention relates to a sintered light-weight environment-friendly brick produced from electroplating sludge and a manufacture method thereof. The sintered light-weight environment-friendly brick is characterized by being prepared by adopting electroplating sludge, base waste sludge, furnace slag, refuse ash, calcium oxide, calcium sulfate, sodium carbonate, boric acid, ferrous sulfate, magnesium sulfate, Li macromolecular heavy metal trapping agent and water are adopted as raw materials; and the manufacture method comprises the following steps of: mixing and stirring the raw materials in a biaxial mixer to be in a moisture state; extruding into rectangular bars by a vacuum sludge extruder; cutting and forming by a blank cutter; manufacturing light-weight environment-friendly brick blanks of electroplating sludge under the pressure of 20-30 MPa; and conveying the formed and naturally dried light-weight environment-friendly brick blanks into a tunnel kiln to roast and manufacture light-weight environment-friendly brick products. Air laying bricks and pavement bricks in different specifications can also be manufactured by the raw materials of the invention, and the product has the advantages and the effects of light weight, great strength, zero pollution, low cost and good benefits.

Owner:清远绿由环保科技有限公司

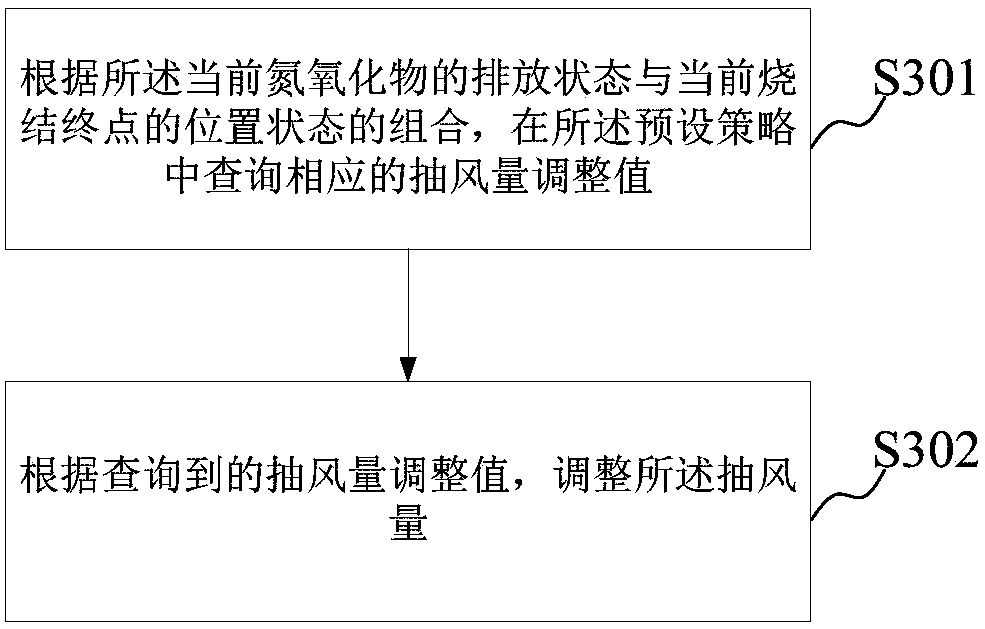

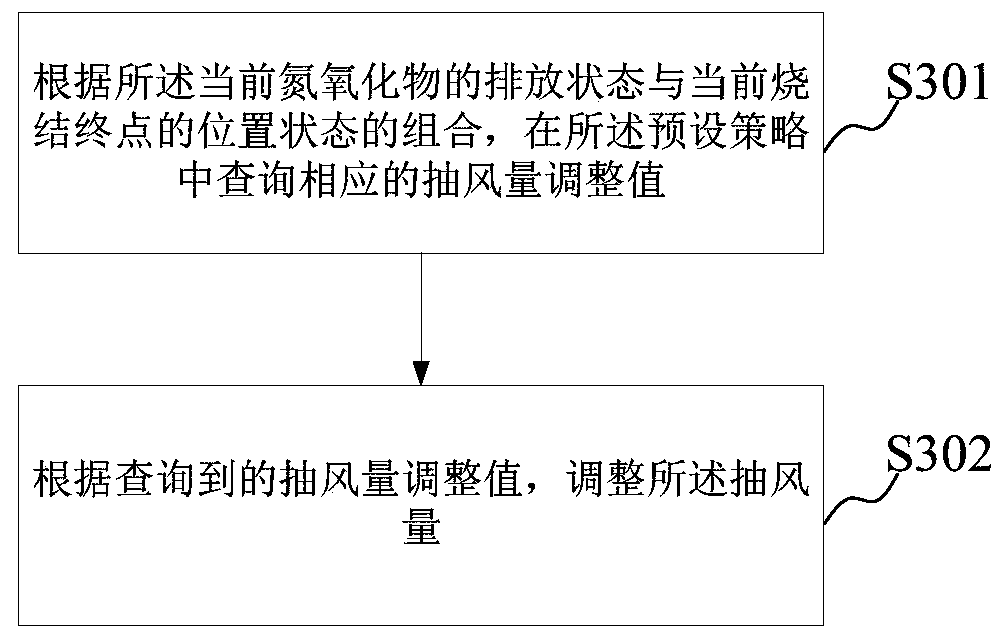

Nitrogen oxide emission control method and device

ActiveCN108267025AReduce thicknessReduce the chance of spawningControl devices for furnacesNitrogen oxidesMetallurgy

The embodiment of the invention provides a nitrogen oxide emission control method and device. The method comprises the steps of obtaining the current nitrogen oxide emission state; obtaining the current positional state of a sintering final point; and according to the current nitrogen oxide emission state, the current positional state of the sintering final point and a preset strategy, adjusting the air draft capacity of a sintering system. According to the nitrogen oxide emission control method and device, the air draft capacity of the sintering system is adjusted according to the current nitrogen oxide emission state, the current positional state of the sintering final point and the preset strategy, so that on the premise that it is guaranteed that the sintering final point is at the reasonable position, the air blast capacity is properly increased, and the sintering speed, namely the vertical sintering speed, achieved in the sintering process can be increased; thus, the thickness ofa burning belt is reduced; furthermore, the generation probability of nitrogen oxide is lowered; the cost is low, and in addition, physical properties of sintered ore are not affected; and quality ofthe sintered ore can be guaranteed.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Production method of multifunctional quincuncial gypsum tailings lightweight through-hole ceramsite

InactiveCN106431337AHigh porositySpeed up dryingCeramic materials productionCeramicwareMicrosphereLandscaping

The invention discloses a production method of multifunctional quincuncial gypsum tailings lightweight through-hole ceramsite. A technical scheme of the method is characterized in that burden is subjected to stirring, extrusion granulating, drying, calcining, heat insulation, screening and hermetic packaging to obtain multifunctional quincuncial gypsum tailings lightweight through-hole ceramsite; the burden is prepared from gypsum tailings, high-viscosity attapulgite clay, zeolite, activated white clay waste, activated alumina, nano zinc oxide, lightweight magnesium oxide, lightweight calcium carbonate, hollow microspheres, expanded perlite, expanded vermiculite and sodium dodecyl sulfate; the ceramsite features good adsorbing performance, large effective specific surface area, high porosity, small bulk density, light weight but high strength, and integration of micropores and macropores, and is suitable for various greening projects, such as water purification and filtering, soil restoration, landscaping, roof greening, and desert control; the production method of the multifunctional quincuncial gypsum tailings lightweight through-hole ceramsite is suitable for the production of multifunctional gypsum tailings lightweight through-hole ceramsite in different shapes, such as quincuncial shape, cylindrical shape and spherical shape.

Owner:甘肃华晨生态治理有限公司

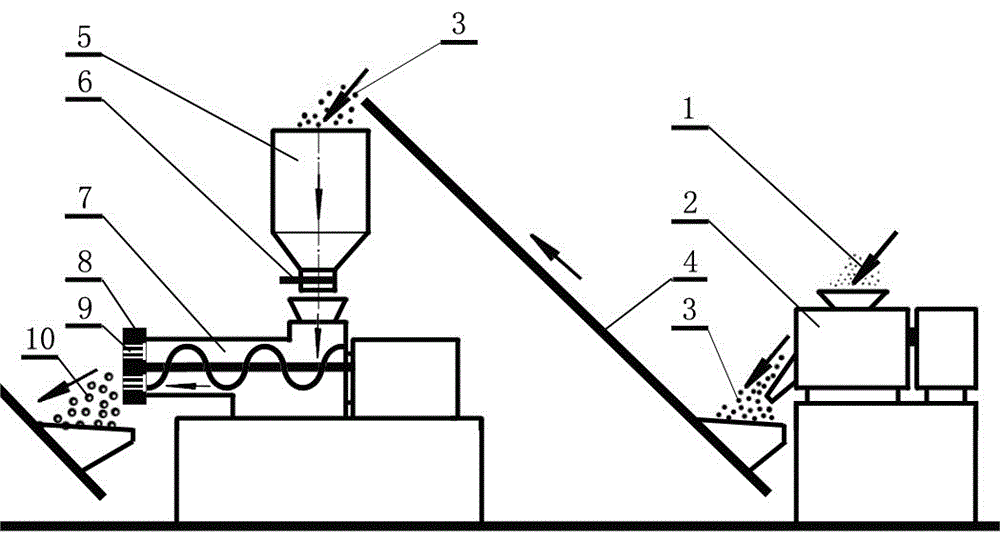

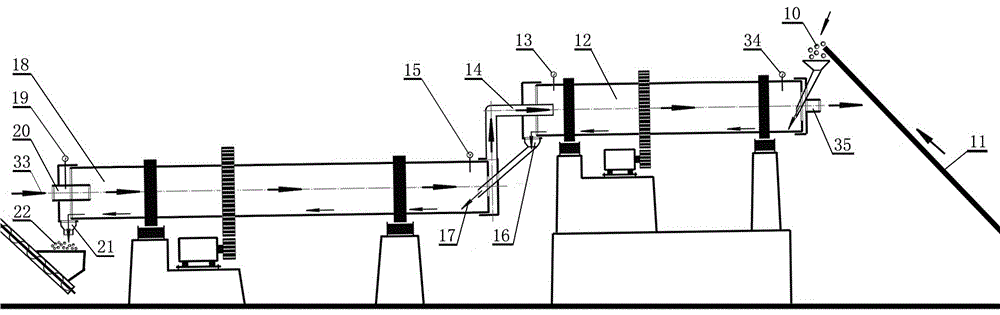

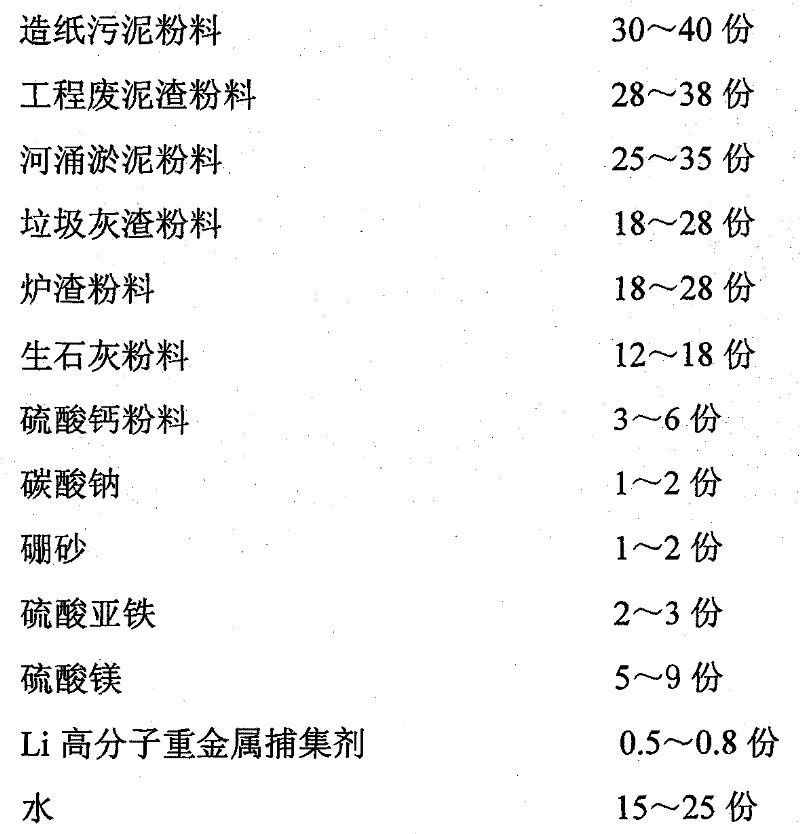

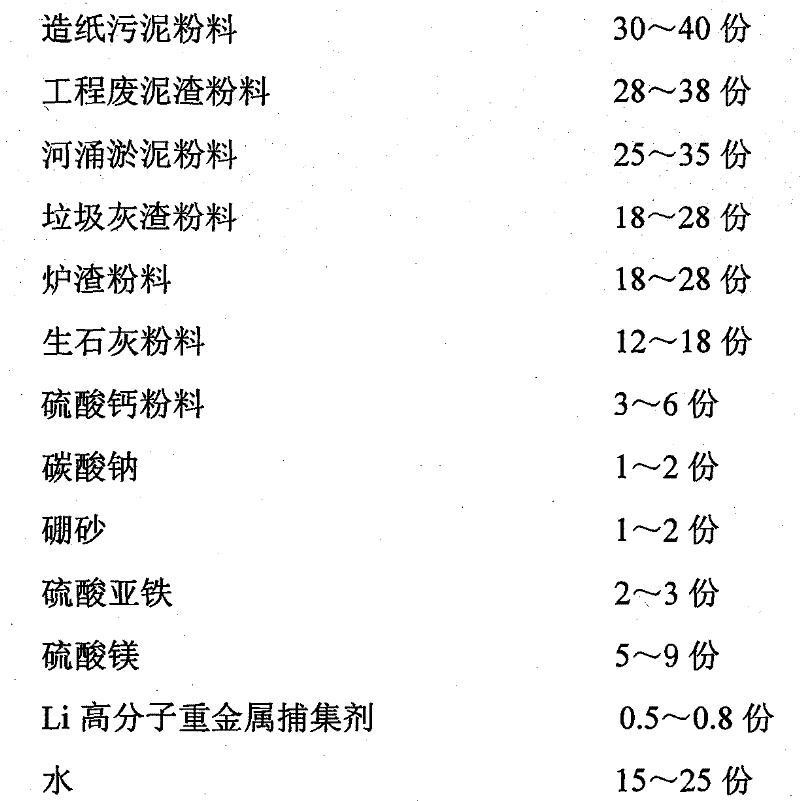

Baked light-weight environmental-friendly bricks prepared from paper mill sludge and manufacturing method thereof

ActiveCN101913842BFast dryingImprove performanceSolid waste managementBuilding componentsTunnel kilnBrick

The invention relates to baked light-weight environmental-friendly bricks prepared from paper mill sludge and a manufacturing method thereof. The method is characterized by comprising the following steps of: mixing the paper mill sludge, engineering waste sludge, river sludge, refuse ash, slag, ground quick lime, calcium sulfate, sodium carbonate, borax, ferrous sulphate, magnesium sulfate, Li high molecular heavy metal collector, water and the like serving as raw materials, stirring the mixture into a damp product by using a double-shaft mixer and extruding the damp product into a rectangular strip-shaped product by using a de-airing extruder; cutting and molding the extruded product by using a blank cutter; manufacturing paper mill sludge light-weight environmental-friendly bricks underthe pressure of between 20 and 30 MPa; feeding the molded and naturally-dried light-weight environmental-friendly bricks into a tunnel kiln by using a battery car to bake the bricks; and obtaining light-weight environmental-friendly brick products after baking. The raw materials can be prepared into hollow bricks and sidewalk bricks with different specifications. The product has the advantages oflight weight, high intensity, no pollution, low cost and good benefit.

Owner:清远绿由环保科技有限公司

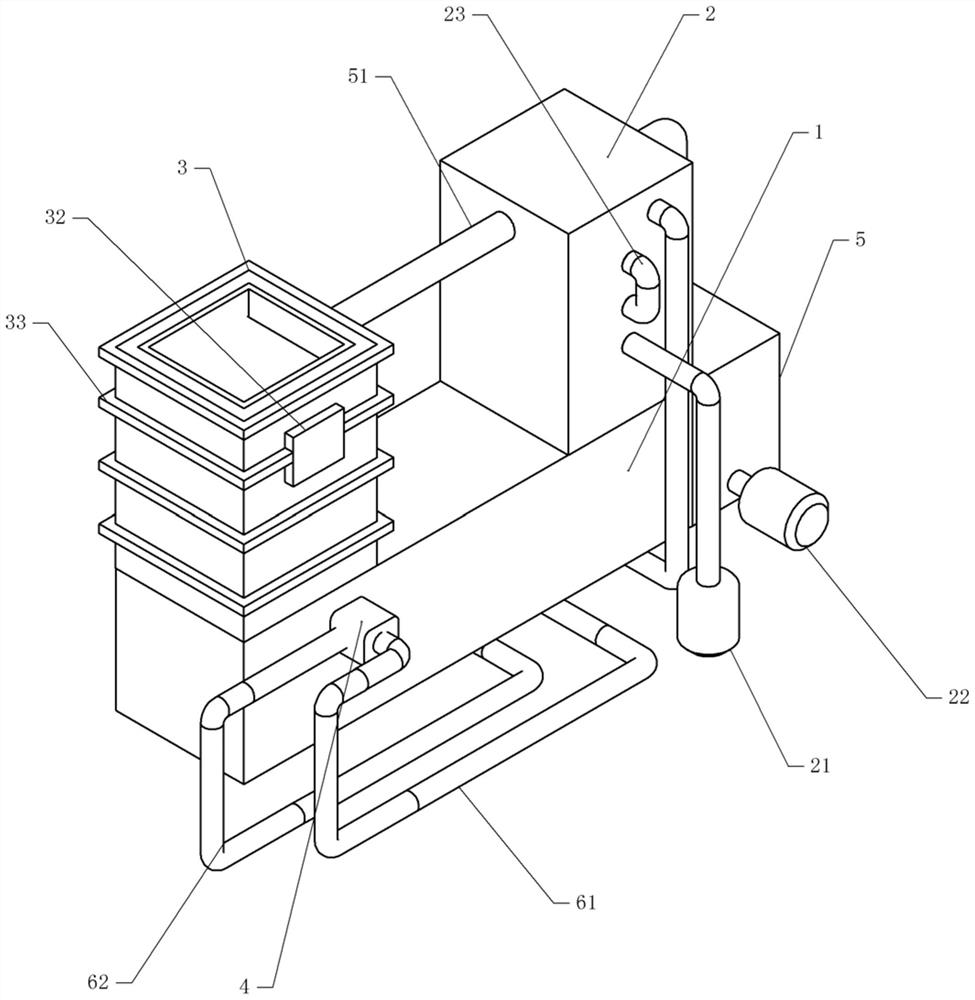

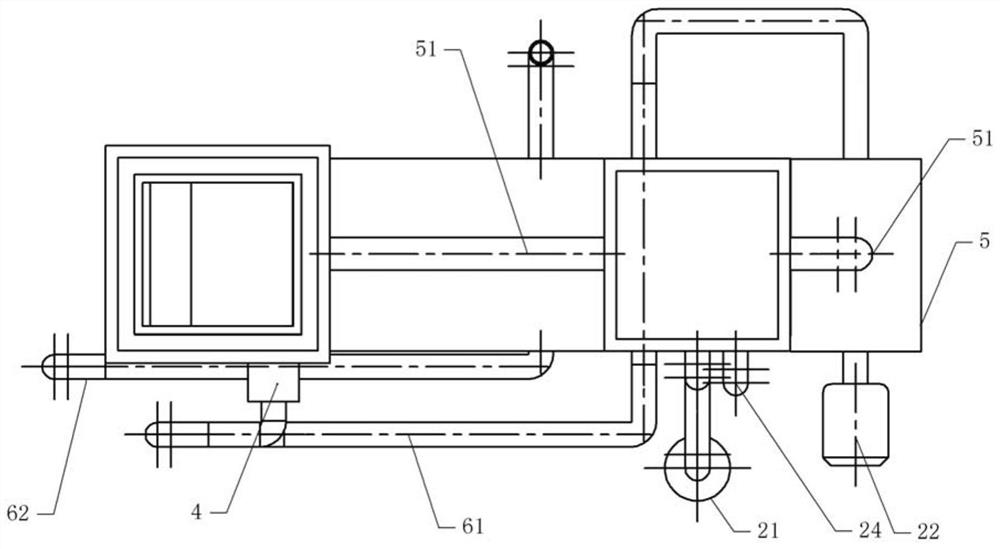

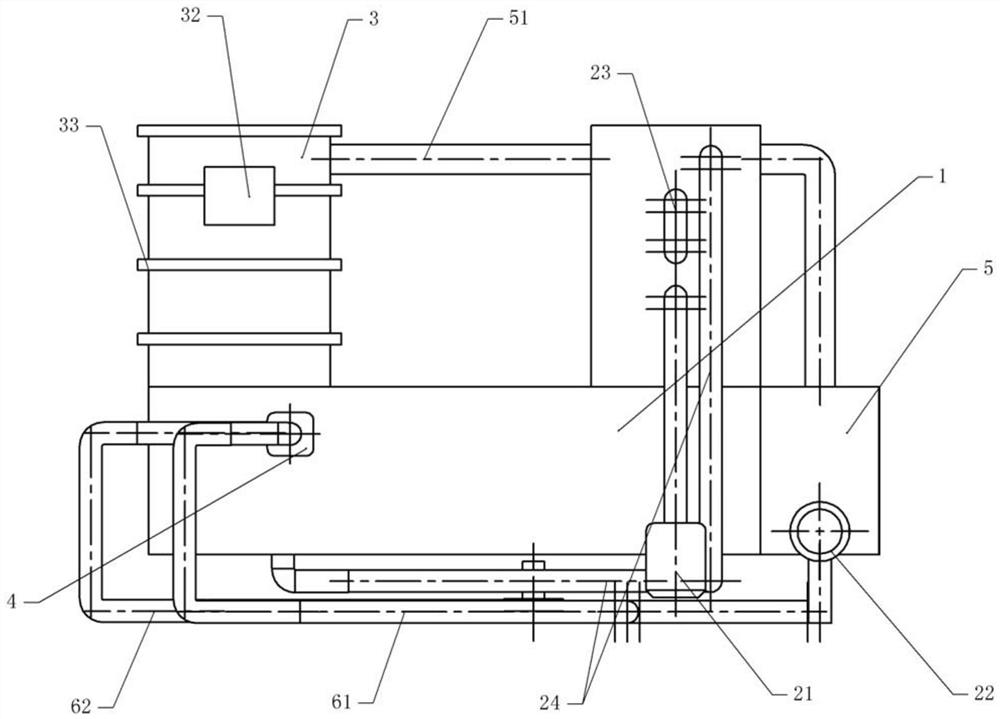

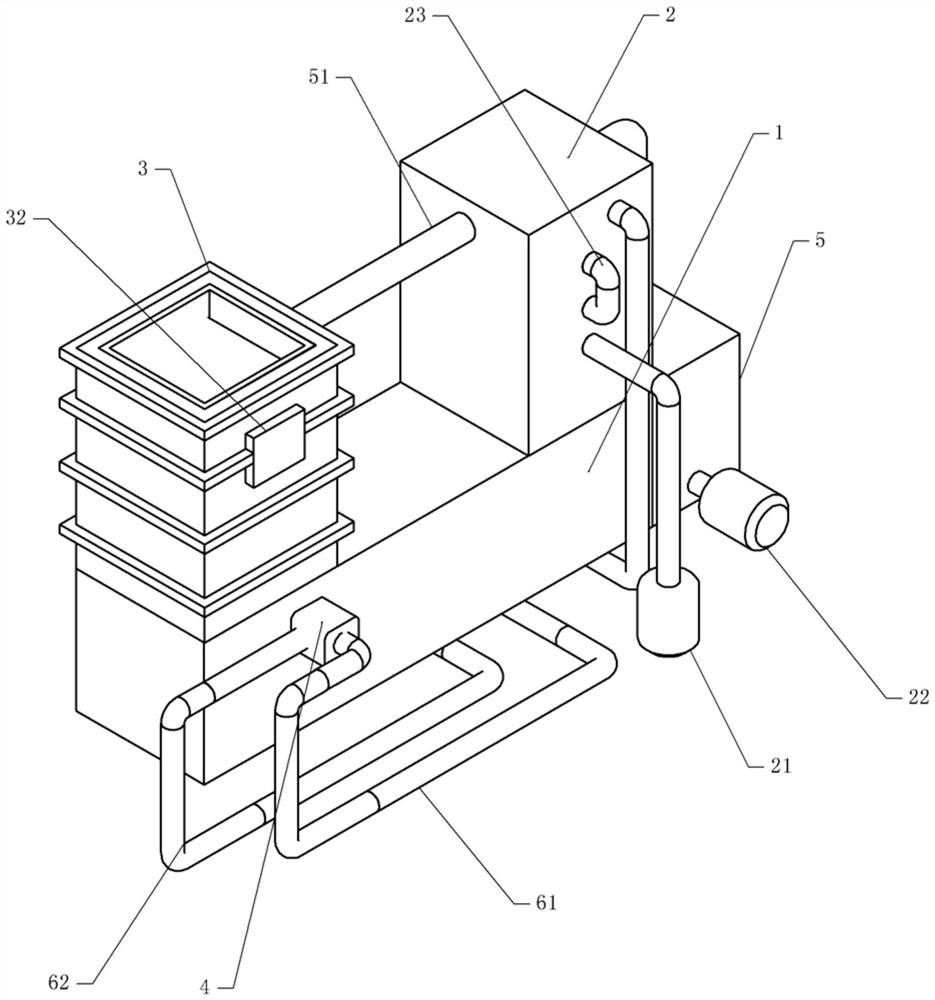

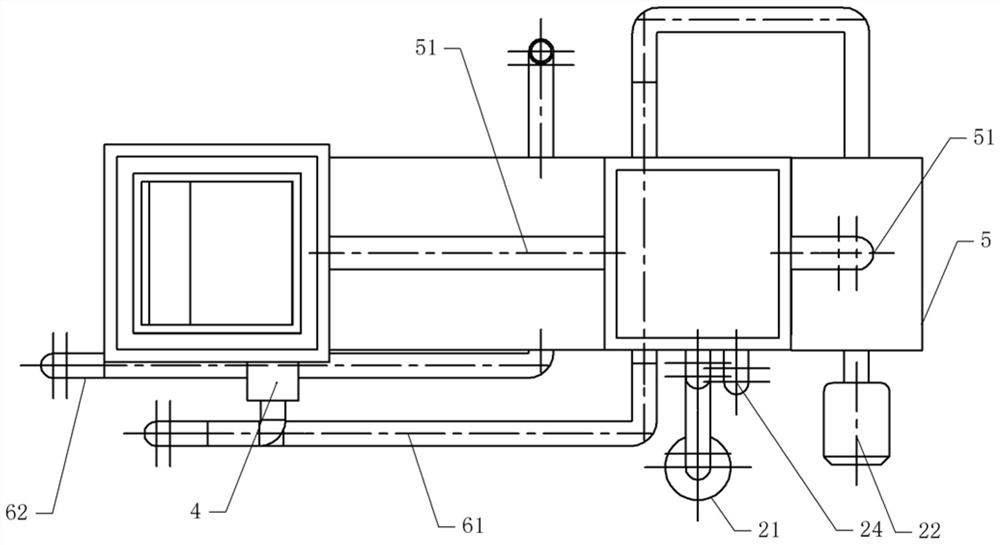

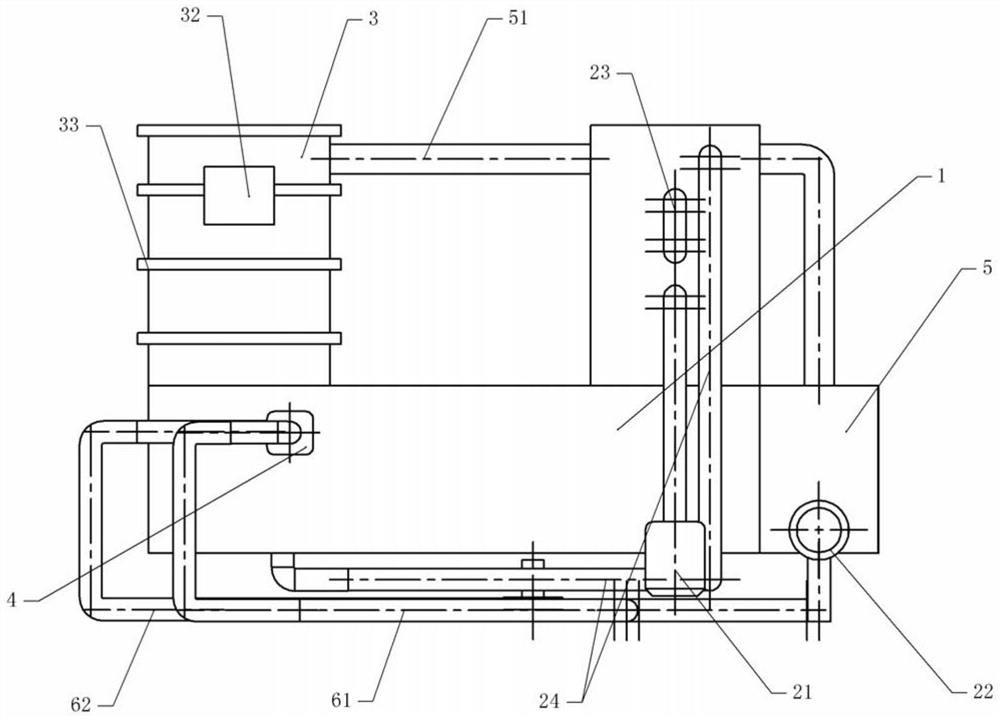

Regenerative precoated sand roasting furnace

PendingCN112091163AIncrease temperatureReduce roasting costCharge treatment typePreheating chargesThermodynamicsCombustion chamber

The invention relates to the technical field of precoated sand roasting energy conservation, and discloses a regenerative precoated sand roasting furnace. The regenerative precoated sand roasting furnace comprises a body, wherein a combustion chamber is arranged in the body, an igniter facing the interior of the combustion chamber is installed on the body, the regenerative precoated sand roastingfurnace comprises a feeding chamber fixed to one side of the body, one side of the combustion chamber communicates with the feeding chamber, the side, away from the feeding chamber, of the combustionchamber communicates with a preheating bag, and the preheating bag communicates with a waste gas pipe; a baffling channel is arranged in the feeding chamber, and a preheating cavity communicating withthe waste gas pipe is formed in the side wall of the feeding chamber; and the preheating cavity communicates with the waste gas pipe. The regenerative precoated sand roasting furnace is simple in structure, waste gas exhausted from the combustion chamber is fed into the feeding chamber to preheat sand, the sand with a certain temperature enters the combustion chamber, heat consumption in the combustion chamber can be reduced, then use of natural gas is reduced, and the roasting cost of the sand is reduced.

Owner:重庆市益环覆膜砂有限公司

Porous brick, hollow brick prepared from waste hydrochloric acid liquid containing iron and its preparation method

The invention discloses a porous brick and hollow brick with waste ferric alcaine liquid, which comprises the following parts: 30-50% clay, 40-60% shale, 10-20% coal slag, inferior coal, coal ash, coal waste or their mixture, 1-3% waste of ferric ore, wherein the particle of each material is less than 1mm. The preparing method comprises the following steps: stirring waste ferric alcaine liquid and supernatant reacted by waste iron filling and ferric ore waste and all components completely; blending evenly; aging; compressing; stirring; squeezing; cutting mould; piling mould; stewing; drying; sintering; cooling naturally.

Owner:王铁林

A method and device for controlling nitrogen oxide emissions

ActiveCN108267024BReduce thicknessReduce spawn rateControl devices for furnacesNitrogen oxidesMetallurgy

The embodiment of the invention provides a nitrogen oxide emission control method and device. The method comprises the steps of obtaining the current nitrogen oxide emission state; obtaining the current positional state of a sintering final point; and according to the current nitrogen oxide emission state, the current positional state of the sintering final point and a preset strategy, adjusting the temperature of a material layer. According to the nitrogen oxide emission control method and device, the temperature of the material layer is adjusted according to the current nitrogen oxide emission state, the current positional state of the sintering final point and the preset strategy, so that on the premise that it is guaranteed that the sintering final point is at the reasonable position,the temperature of the material layer is properly raised, and the sintering speed, namely the vertical sintering speed, achieved in the sintering process can be increased; thus, the thickness of a burning belt is reduced; furthermore, the generation probability of nitrogen oxide is lowered; the cost is low, and in addition, physical properties of sintered ore are not affected; and quality of the sintered ore can be guaranteed.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Regenerative precoated sand roasting furnace preheating system

PendingCN112082389AReduce calorie consumptionReduce usageCharge treatment typePreheating chargesProcess engineeringManufacturing engineering

The invention relates to the technical field of precoated sand roasting energy conservation, and discloses a regenerative precoated sand roasting furnace preheating system. The system comprises a feeding chamber and a preheating bag. The preheating bag is used for collecting waste gas and roasted sand grains. A baffling channel is formed in the feeding chamber, and a preheating chamber used for preheating the sand grains is formed in the side wall of the feeding chamber. The upper part of the preheating bag communicates with a waste gas pipe, and the waste pipe communicates with the preheatingchamber. The regenerative precoated sand roasting furnace preheating system is simple in structure, can preheat the sand grains which enter the roasting furnace, loss of heat in the roasting furnaceis reduced, then consumption of natural gas is reduced, and the purpose of saving energy is achieved.

Owner:重庆市益环覆膜砂有限公司

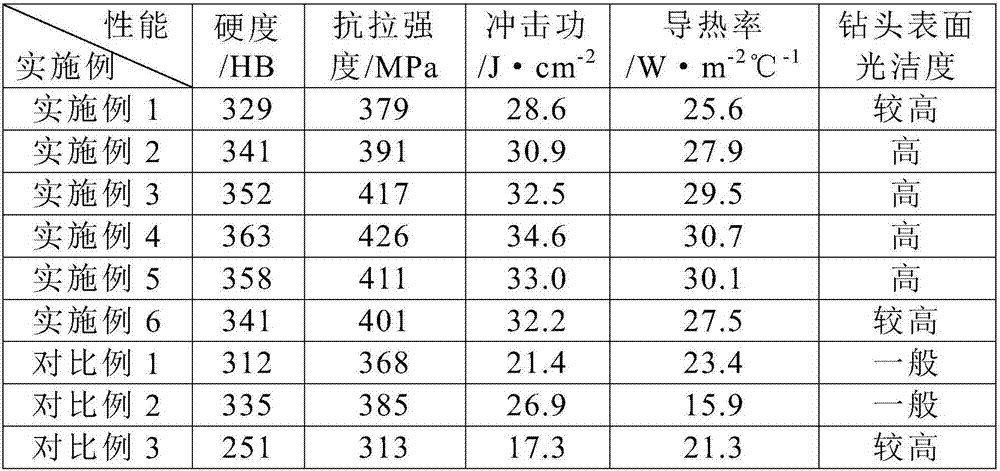

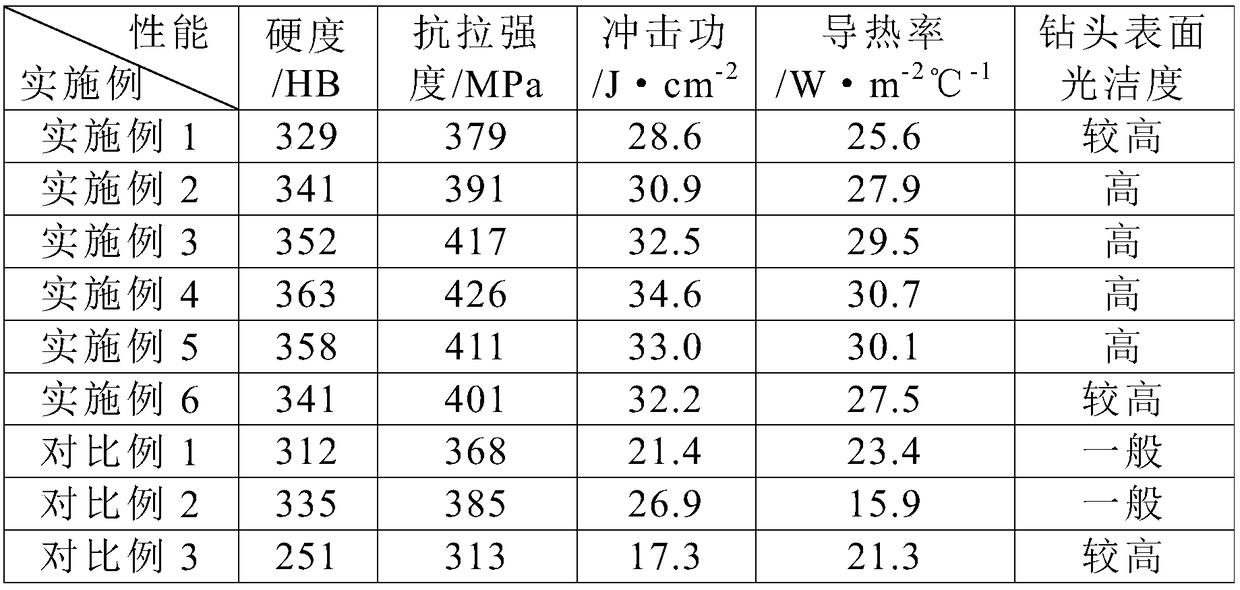

Preparation method for high-precision drilling bit

InactiveCN107096885AClear edges and cornersHigh dimensional accuracyFoundry mouldsFoundry coresWaxDrill bit

The invention relates to a method for preparation method for a high-precision drilling bit, and belongs to the technical field of casting. The preparation method includes shell preparing, roasting, melting casting and postprocessing, wherein the shell preparing comprises the steps: spraying a coating on a surface of a preformed fusible wax molding, sandblasting, drying, then dewaxing, preparing a shell green body, spraying the coating, and repeating the sandblasting and drying step for 2 to 5 times; the roasting comprises the steps: putting the shell green body into a roasting furnace, and roasting under a vacuum degree with 0.08 to 0.20MPa to obtain a shell. The drilling bit prepared by the invention is small in error, accurate in size and smooth in surface.

Owner:宁波神钻工具有限公司

Double-blowing two-seat two-row vertical pellet-roasting furnace

The double-blowing two-seat two-row vertical pellet-roasting furnace includes stoving bed, blast guiding chamber, dust laying chamber, blast guiding pipe, combustor, roasting chamber, roasting blast distributing chamber, material laying unit, material distributing unit and pre-drying unit. It features the complex furnace form with burners on two sides of the roasting band, cooling jets on two sides of the cooling band, air exhaust ports on two sides of the end of the cooling band, dust laying chamber below the blast guiding chamber and the pellet pre-drying unit over the stoving bed. The present invention has improved heating, cooling and ventilating mechanisms of vertical furnace, and has the advantages of reinforced roasting, reinforced cooling, reinforced drying, controllable airflow motion, etc.

Owner:NORTHEASTERN UNIV LIAONING

A method and device for controlling nitrogen oxide emissions

ActiveCN108267008BReduce thicknessReduce spawn rateFurnace typesControl devices for furnacesCombustionMetallurgy

The embodiment of the invention provides a nitrogen oxide emission control method and device. The method comprises the following steps that the emission state of current nitrogen oxide is acquired; the position state of a current sintering end point is obtained; and the thickness of a material layer is adjusted according to the emission state of the current nitrogen oxide, the position state of the current sintering end point and a preset strategy. In the embodiment of the nitrogen oxide emission control method and device, according to the emission state of the current nitrogen oxide, the position state of the current sintering end point and the preset strategy, the thickness of the material layer is adjusted, under the premise that the sintering end point is ensured to be at a reasonableposition, the thickness of the material layer is properly reduced so as to improve air permeability of the material layer, the roasting speed (namely the vertical sintering speed) of the sintering process can be increased, so that the thickness of a combustion zone is reduced, and therefore the probability of nitrogen oxide generation is reduced, cost is low, the physical property of sintered oreis not influenced at the same time, and the quality of the sintered ore can be guaranteed.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

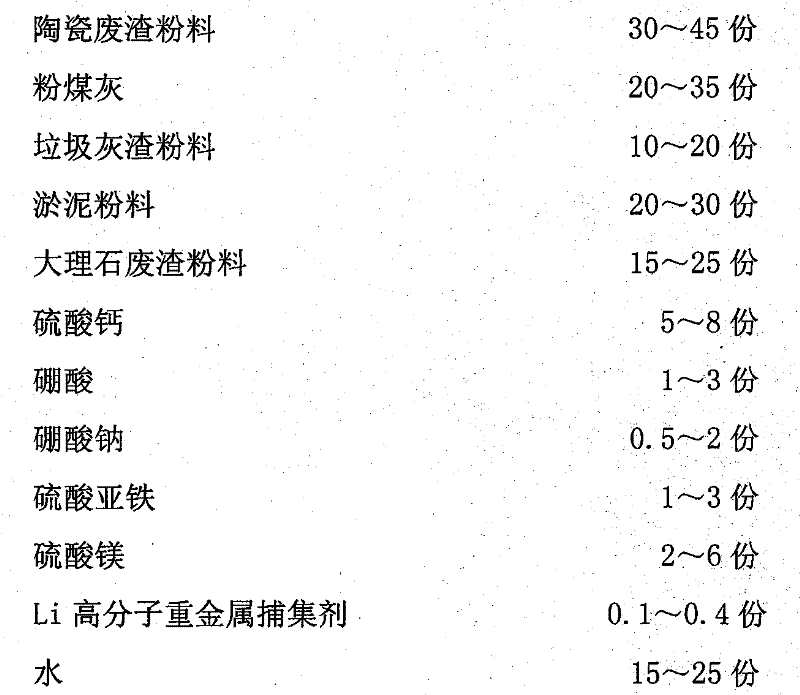

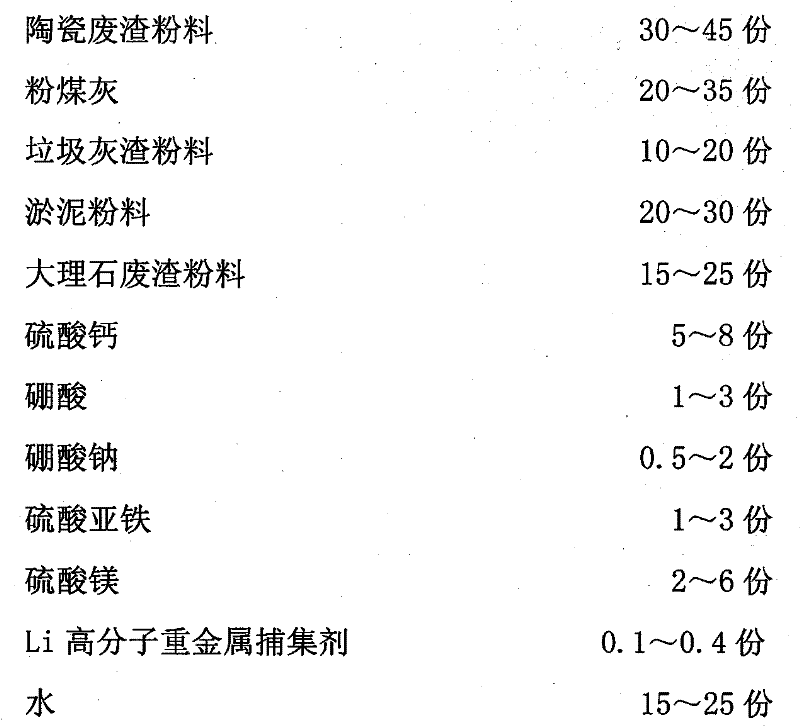

Sintered light environmentally-friendly brick produced from ceramic waste residues and silt and manufacturing method thereof

The invention relates to a sintered light environmentally-friendly brick produced from ceramic waste residues and silt and a manufacturing method thereof. The method is characterized by comprising the following steps of: mixing the ceramic waste residues, the silt, fly ash, garbage ash residues, marble waste residues, calcium sulfate, boric acid, sodium borate, ferrous sulfate, magnesium sulfate, a Li high molecular heavy metal collector and water serving as raw materials; stirring by using a double-shaft stirrer; extruding by using a de-airing extruder after the raw materials are wet; cutting and forming by using a blank cutter; manufacturing a light environmentally-friendly brick blank of the ceramic waste residues and the silt under the pressure of between 20 and 30Mpa; and feeding the formed and naturally dried light environmentally-friendly brick blank into an annular kiln by using a battery truck for baking to prepare a light environmentally-friendly brick product of the ceramic waste residues and the silt. The raw materials can also be used for preparing hollow blocks and pedestrian road bricks of different specifications; and the product has the advantages of light weight, high strength, no pollution, low cost and good benefit.

Owner:清远绿由环保科技有限公司

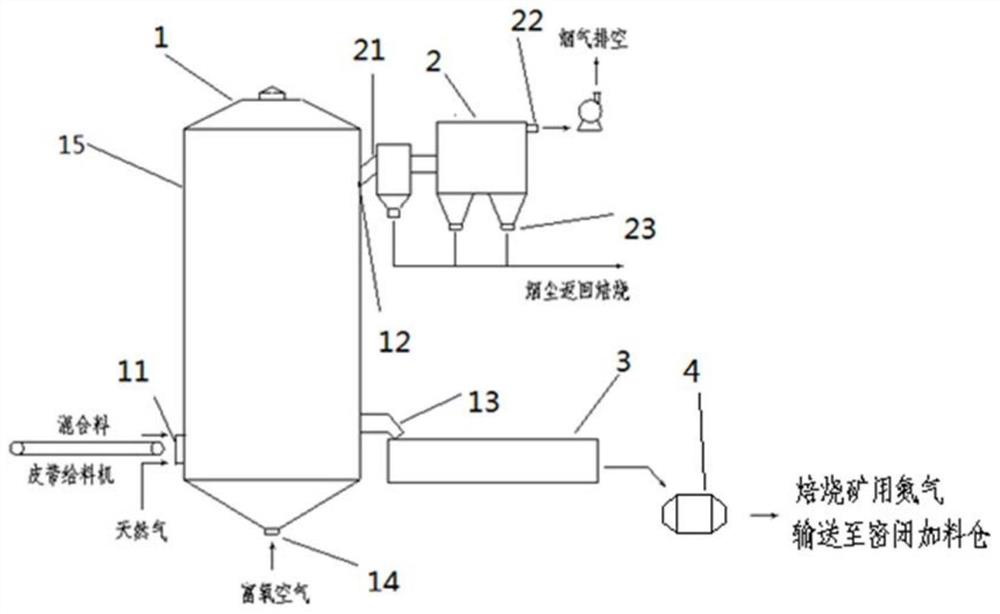

Preparation method and equipment of manganese removal agent

PendingCN114408980ASpeed up roastingShorten roasting timeFluidised-bed furnacesManganates/permanganatesFluidized bedEngineering

The invention belongs to a pyrometallurgy technology, and particularly relates to a preparation method and equipment of a manganese removal agent for wet zinc smelting. Equipment for producing a manganese removal agent comprises a fluidized bed furnace, a cyclone and ceramic tube dust collector and a water cooling cylinder, the fluidized bed furnace comprises a furnace body, a fluidized bed furnace exhaust port is formed in the top of the furnace body, and a fluidized bed furnace feeding port, a fluidized bed furnace air inlet and a fluidized bed furnace discharging port are formed in the bottom of the furnace body; a discharge hole of the fluidized bed furnace is communicated with the water cooling cylinder; the cyclone and ceramic tube dust collector is provided with a smoke inlet, a smoke outlet and an air outlet; the fluidized bed furnace air outlet is communicated with the smoke dust air inlet; the air outlet is communicated with the outside atmosphere; and the smoke dust discharge port is communicated with the feed port of the fluidized bed furnace. The smoke dust produced by the fluidized bed furnace is high in rate, and the smoke dust returns to fluidized bed roasting so as to improve the sintering conversion rate. The sintering conversion rate of the sodium manganate can reach 90% or above.

Owner:CINF ENG CO LTD

A kind of preparation method of high-precision drill bit

InactiveCN107096885BClear edges and cornersHigh dimensional accuracyFoundry mouldsFoundry coresWaxAbrasive blasting

The invention relates to a method for preparation method for a high-precision drilling bit, and belongs to the technical field of casting. The preparation method includes shell preparing, roasting, melting casting and postprocessing, wherein the shell preparing comprises the steps: spraying a coating on a surface of a preformed fusible wax molding, sandblasting, drying, then dewaxing, preparing a shell green body, spraying the coating, and repeating the sandblasting and drying step for 2 to 5 times; the roasting comprises the steps: putting the shell green body into a roasting furnace, and roasting under a vacuum degree with 0.08 to 0.20MPa to obtain a shell. The drilling bit prepared by the invention is small in error, accurate in size and smooth in surface.

Owner:宁波神钻工具有限公司

A method and device for controlling nitrogen oxide emissions

ActiveCN108267025BReduce thicknessReduce the chance of spawningControl devices for furnacesNitrogen oxidesMetallurgy

The embodiment of the invention provides a nitrogen oxide emission control method and device. The method comprises the steps of obtaining the current nitrogen oxide emission state; obtaining the current positional state of a sintering final point; and according to the current nitrogen oxide emission state, the current positional state of the sintering final point and a preset strategy, adjusting the air draft capacity of a sintering system. According to the nitrogen oxide emission control method and device, the air draft capacity of the sintering system is adjusted according to the current nitrogen oxide emission state, the current positional state of the sintering final point and the preset strategy, so that on the premise that it is guaranteed that the sintering final point is at the reasonable position, the air blast capacity is properly increased, and the sintering speed, namely the vertical sintering speed, achieved in the sintering process can be increased; thus, the thickness ofa burning belt is reduced; furthermore, the generation probability of nitrogen oxide is lowered; the cost is low, and in addition, physical properties of sintered ore are not affected; and quality ofthe sintered ore can be guaranteed.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

A recycled brick made from papermaking sludge and its preparation method

InactiveCN103130492BHigh densityIncrease profitCeramic materials productionClaywaresBreaking strengthBrick

The invention relates to a regenerated brick prepared from papermaking sludge and a preparation method thereof. the invention solves the problem of restricted utilization ratio of bricks prepared from papermaking sludge, and overcomes the defects of low compression resistance, low breaking strength, poor air permeability and the like in the bricks prepared from papermaking sludge. The preparation method comprises the following steps: mixing and stirring 35-40 parts by weight of papermaking sludge with the water content of 45-55%, 20-25 parts by weight of power plant sintering ash, 40-45 parts by weight of clay, 2.5-4 parts by weight of flame-retardant permeable fiber monofilament, 3-5 parts by weight of blind coal, 3-5 parts by weight of water-soluble resin and 4-7 parts by weight of water to obtain a wet material; and extruding with an extruding machine to obtain a blank strip, cutting into green bricks, naturally drying in air, and sintering in a kiln.

Owner:FUJIAN YIYUAN WASTE UTILIZATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com