Burner

A burner and pipeline technology, which is applied in the field of burners, can solve problems such as changing the flame and the influence of the roasting quality of the materials used to make cement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

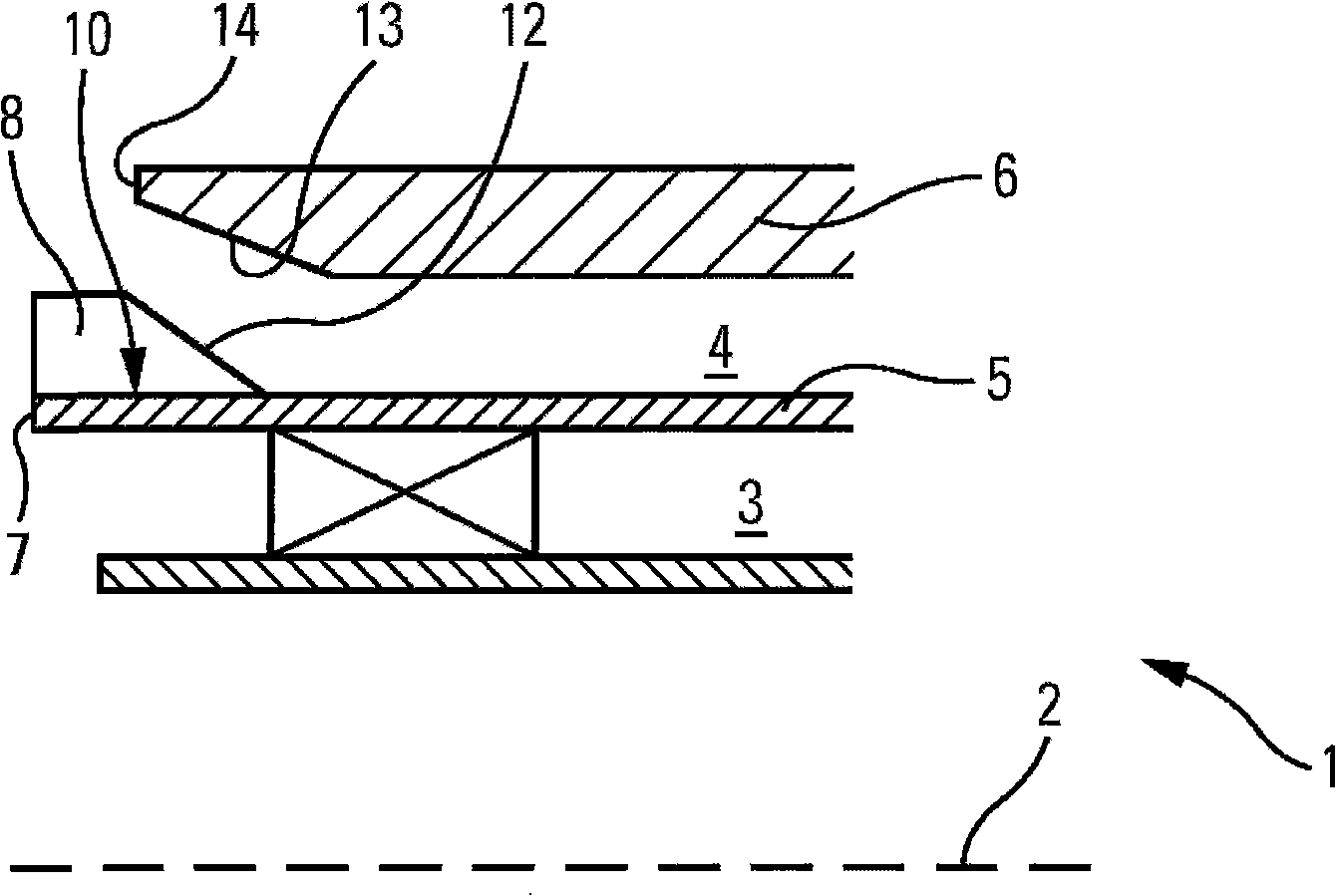

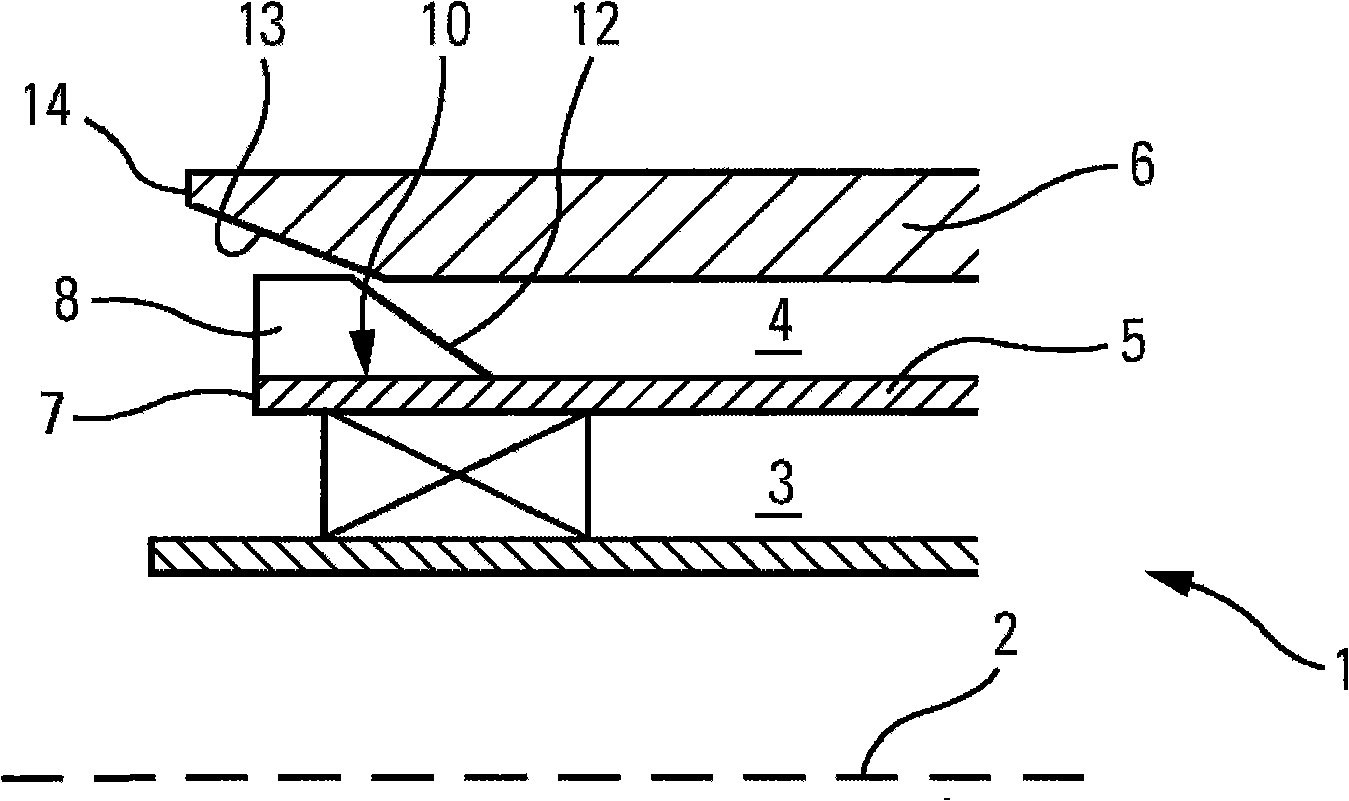

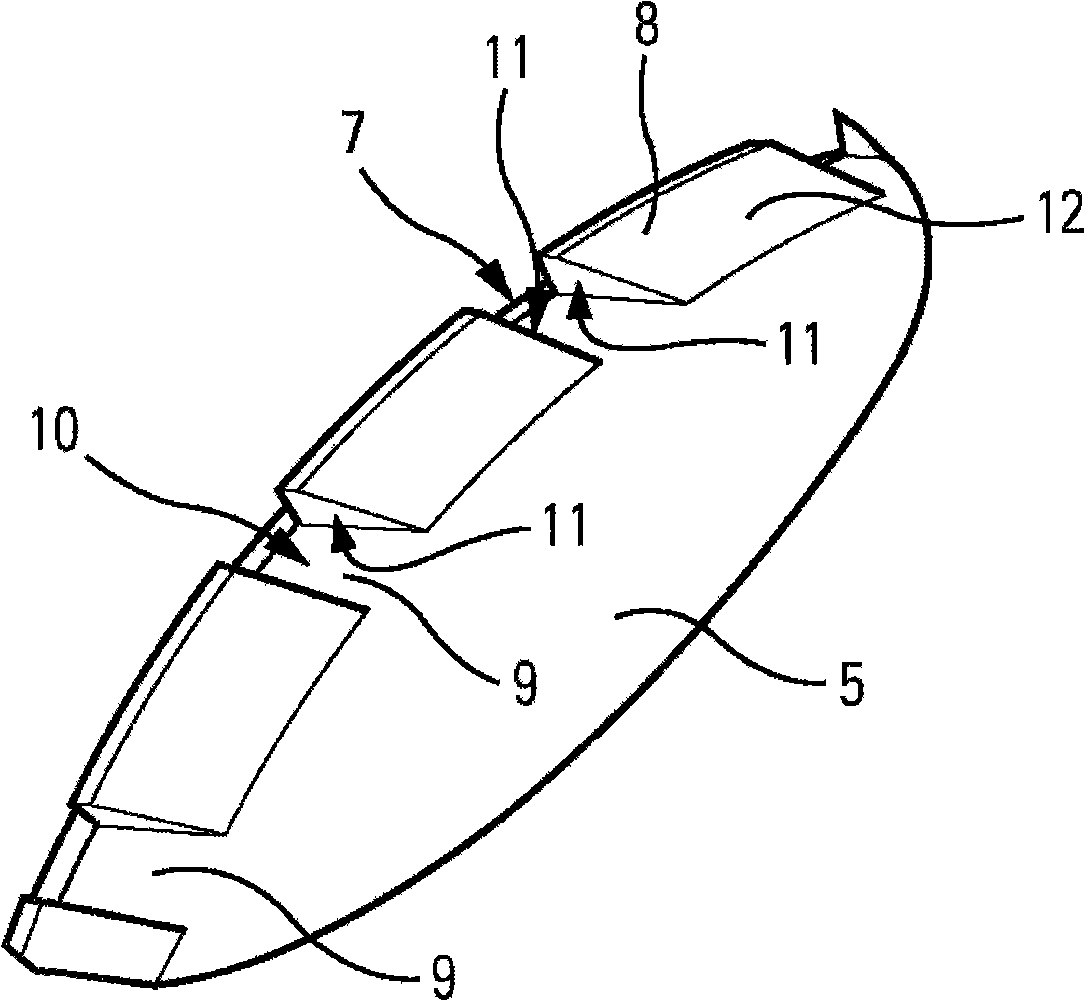

[0013] figure 1 A part of a burner 1 is shown which extends along an axis 2 and generally comprises a solid and / or fluid and / or gaseous fuel supply line and a central air delivery line which is used to make the The flame can be fixed to the flame holder and the central air delivery line can be cooled.

[0014] In the present example, the burner 1 also comprises a tangential primary air supply peripheral line 3 surrounding the central air supply line and all fuel supply lines. This tangential primary air supply peripheral line 3 comprises means capable of imparting a tangential component to the air flow at its outlet. On the other hand, preferably, the tangential flow air supply line 3 corresponds to any one disclosed in the two patent applications FR 2,887,597 and FR 06 04,829.

[0015] The burner 1 also comprises an axial primary air supply peripheral line 4 whose outlet is such that the air flows substantially axially, i.e. without a tangential component (or at least its t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com