Preparation method and equipment of manganese removal agent

A technology of manganese agent and fluidized fluidized furnace, which is applied in the field of preparation of manganese removal agent for wet zinc smelting, can solve the problems of large energy consumption, discontinuous production, and complicated process, so as to improve the firing conversion rate, increase labor productivity, reduce The effect of roasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

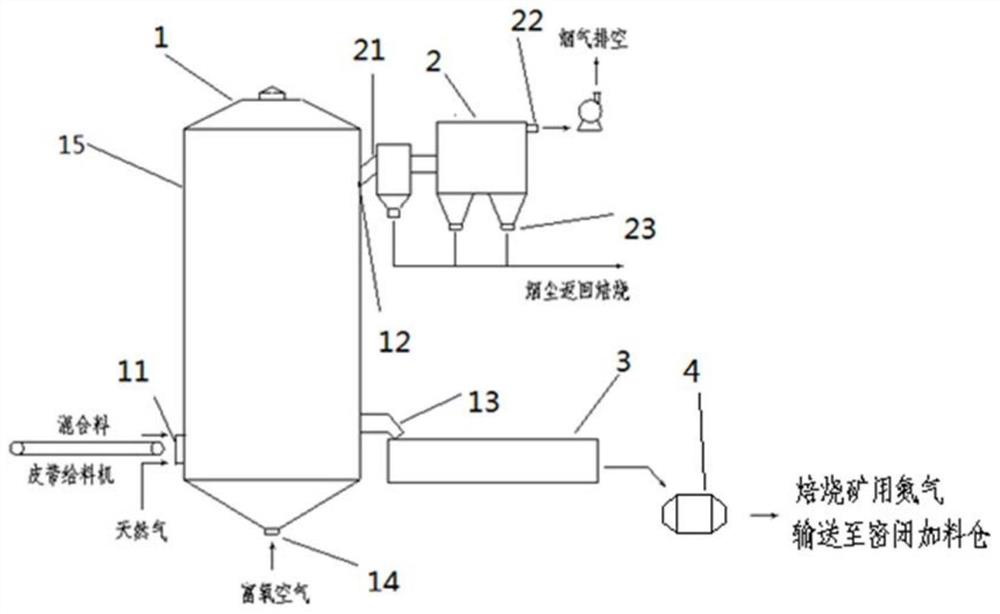

[0038] see figure 1 , the equipment for producing manganese removal agent of the present invention comprises: comprise fluidized bed furnace 1, cyclone and ceramic tube dust collector 2 and water-cooled cylinder 3, ball mill 4, described fluidized bed furnace 1 comprises furnace body 15, and the top of bedded bed furnace 1 is provided with the exhaust gas of the bedded bed furnace 12, the bottom is provided with a fluidized furnace feed port 11, a fluidized furnace inlet 14 and a fluidized furnace discharge port 13; the fluidized furnace discharge port 13 communicates with the water-cooled cylinder 3; Gas port 21, smoke and dust discharge port 23 and gas outlet 22; the exhaust port 12 of the fluidized fluidized furnace communicates with the smoke and dust inlet port 21; the gas outlet 22 communicates with the outside atmosphere; the smoke and dust discharge port 23 communicates with the fluidized furnace feed port 11 , the other end of the water-cooled cylinder 3 communicates ...

Embodiment 2

[0044] The equipment of producing manganese removal agent of the present invention refers to figure 1 .

[0045] Utilize above-mentioned equipment to prepare the method for manganese-removing agent, comprise under certain temperature, carry out boiling roasting to the mixture of pyrolusite powder and sodium hydroxide with oxygen-enriched air, its steps are as follows:

[0046] A. The pyrolusite (containing MnO 2 80%) finely ground to 100 mesh, accounting for 90%, fully mixing the finely ground pyrolusite powder and sodium hydroxide to make a mixture, MnO 2 The mass ratio to NaOH is 1.2:1, and the mixture is continuously thrown to 6m at a speed of 1.80t / h through a belt feeder 2 In the boiling furnace 1;

[0047] B. Inject natural gas from the natural gas nozzle of the fluidized furnace feed port 11, and inject 50% oxygen-enriched air from the fluidized furnace inlet 14 at the bottom of the fluidized furnace, and the total flow rate of the oxygen-enriched air is 3000Nm 3 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com