Sintered light-weight environment-friendly brick produced from printing and dyeing sludge and manufacture method thereof

A technology for printing and dyeing sludge and a manufacturing method is applied in the field of sintering light-weight environmental protection bricks. The sintered light-weight environmental protection bricks can solve the problems of polluted soil and groundwater resources, environmental hazards, complex composition of printing and dyeing sludge, etc. The effect of secondary pollution and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

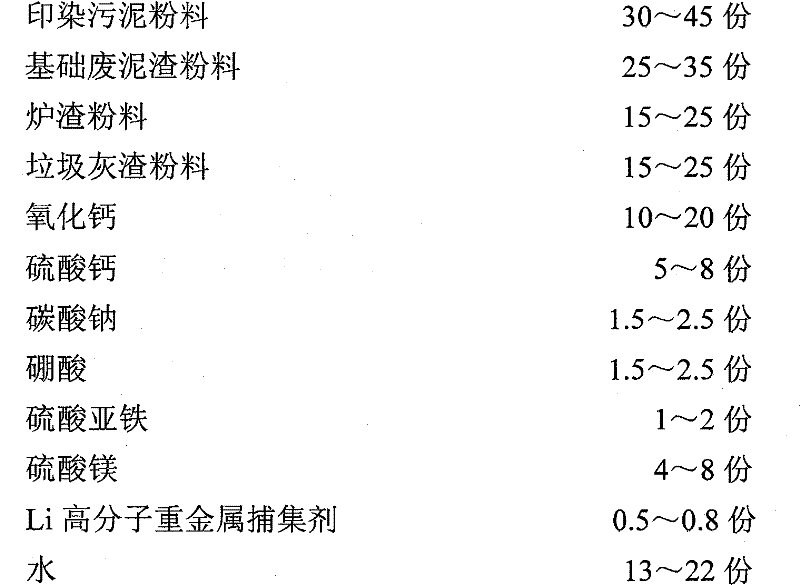

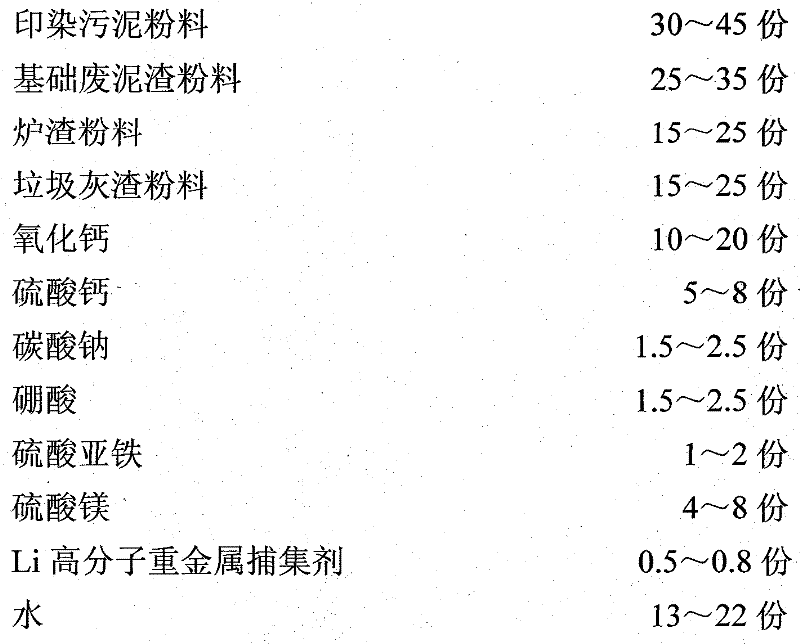

Embodiment 1

[0037] The printing and dyeing sludge separated from the industrial wastewater produced in the textile production and printing and dyeing process of the textile printing and dyeing factory and the domestic sewage discharged from the living area of the factory after treatment is dehydrated, deodorized, disinfected, dried, and chelated. Sludge powder with a particle size of less than 3mm is made after wheel milling and sorting;

[0038]The waste silt generated during the construction of the foundation of the urban residential construction project and the construction of the underground parking lot and the silt and stone solid waste discharged during the construction process of the municipal construction project are sorted, crushed, crushed, screened, and then After wheel milling and sorting, the basic waste sludge powder with a particle size of less than 2mm is made;

[0039] The waste slag discharged from various types of coal after being burned by the boiler is made into sla...

Embodiment 2

[0043] Get the printing and dyeing sludge powder 35kg of embodiment 1, basic waste mud slag powder 28kg, slag powder 18kg, garbage ash powder 18kg, particle diameter be the calcium oxide 13kg of 0.2mm, calcium sulfate 6kg, sodium carbonate 1.8kg , 1.8kg of boric acid, 1.2kg of ferrous sulfate, 5kg of magnesium sulfate, 0.6kg of Li macromolecule heavy metal collector and 15kg of water, the above-mentioned raw materials are mixed and stirred with a twin-shaft mixer to become moist, and then extruded into a rectangular shape using a vacuum extruder The strip shape is cut and formed by a blank cutting machine, and the printed and dyed sludge is made into a light-weight environmentally friendly adobe under a pressure of 23Mpa. After natural drying for 7 days, the formed and naturally dried printed and dyed sludge environmentally friendly adobe is sent to the wheel kiln by a battery car Carry out roasting, and after roasting, make printing and dyeing sludge sintered light-weight envi...

Embodiment 3

[0045] Get embodiment 1 printing and dyeing sludge powder 45kg, basic waste sludge powder 35kg, slag powder 25kg, garbage ash powder 25kg, particle diameter is the calcium oxide 20kg of 0.2mm, calcium sulfate 8kg, sodium carbonate 2.5kg, 2.5kg of boric acid, 2kg of ferrous sulfate, 8kg of magnesium sulfate, 0.8kg of Li polymer heavy metal collector and 22kg of water, the above raw materials are mixed and stirred to become moist, then extruded by mechanical vibration, and printed and dyed under the pressure of 30Mpa Sludge lightweight hollow blocks, after natural drying for 7 days, then the formed and naturally dried printing and dyeing sludge lightweight hollow blocks are sent to the wheel kiln for roasting by a battery car, and after roasting, they are made into printing and dyeing sludge lightweight hollow blocks. Block products. After testing, the average compressive strength is: 8.3Mpa, the minimum value of a single block is: 7.2Mpa, the dry apparent density is: 1022kg / m3,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com