Environment-friendly bricks prepared from waste energy-saving lamp residue and manufacturing method thereof

A manufacturing method and technology for energy-saving lamps, which are applied in building construction, solid waste management, sustainable waste treatment, etc., can solve problems such as water source pollution, air pollution, and environmental pollution, and achieve the effect of avoiding secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The waste slag of waste energy-saving lamps is sorted, crushed, and magnetically separated to remove waste metals and then made into a powder with a particle size of less than 3mm;

[0038] The calcium carbide waste residue is the light gray fine particle suspension sedimentation waste discharged during the production of polyvinyl chloride and vinyl acetate using limestone as raw material in the production of polyvinyl chloride, and the waste metal is removed through dehydration, sorting, crushing and magnetic separation Afterwards, it is made into a powder whose particle size is less than 3 mm.

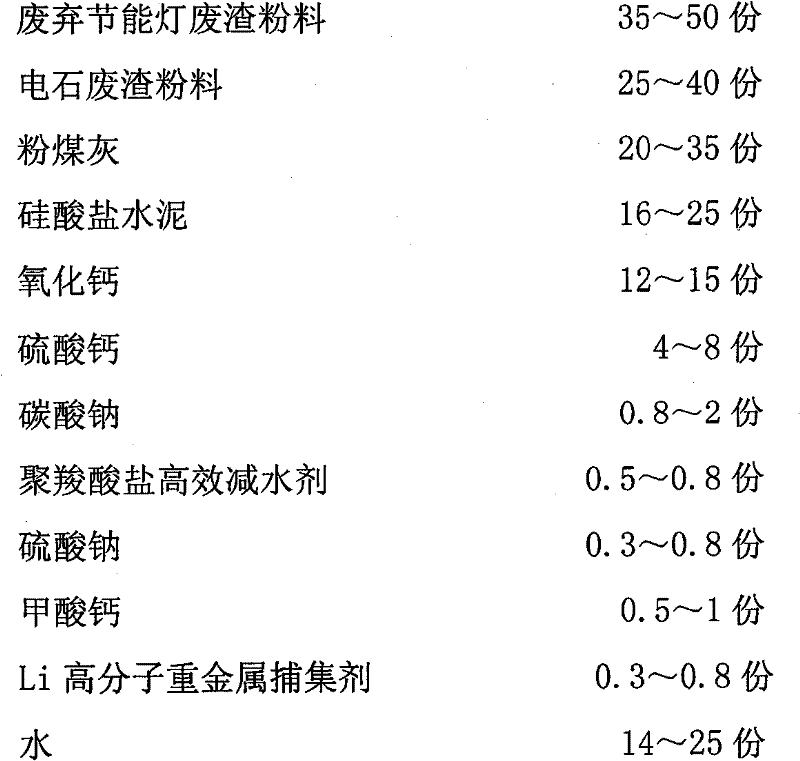

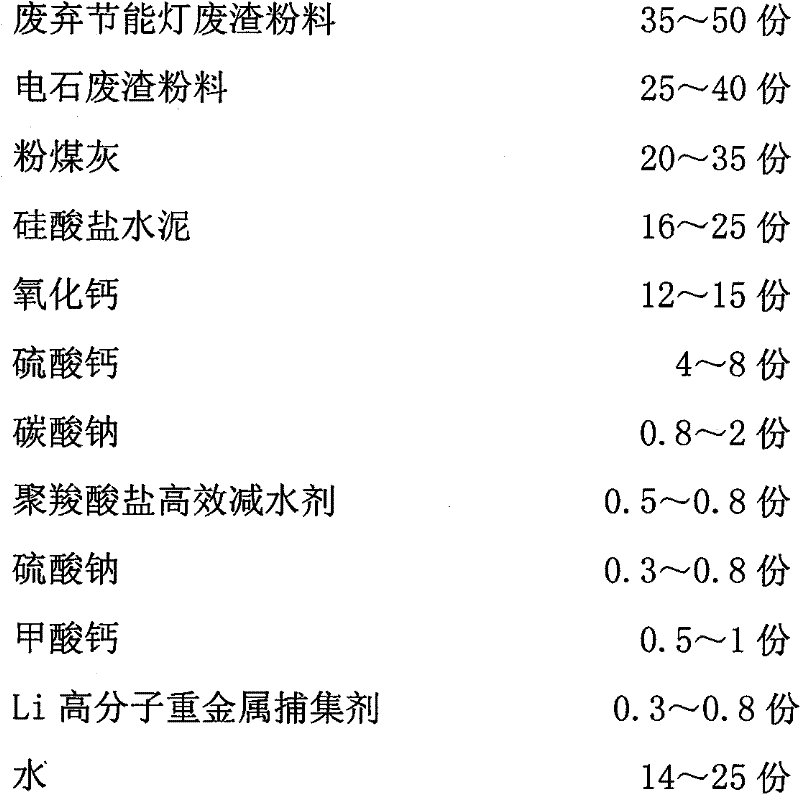

[0039] Get the above-mentioned waste energy-saving lamp waste slag powder 35kg, calcium carbide waste slag powder 40kg, fly ash 20kg, Portland cement 25kg, particle diameter is 12kg of calcium oxide of 0.2mm, calcium sulfate 8kg, sodium carbonate 0.8kg, polycarboxylate Salt high-efficiency superplasticizer 0.8kg, sodium sulfate 0.3kg, calcium formate 1.0kg, Li polymer heavy meta...

Embodiment 2

[0041] Get the discarded energy-saving lamp waste slag powder 40kg of embodiment 1, fly ash 25kg, calcium carbide waste slag powder 30kg, Portland cement 18kg, particle diameter be the calcium oxide 14kg of 0.2mm, calcium sulfate 6kg, sodium carbonate 1.2kg, poly Carboxylate high-efficiency water reducer 0.6kg, sodium sulfate 0.5kg, calcium formate 0.7kg, Li polymer heavy metal collector 0.5kg and water 18kg, mix the above raw materials with a twin-shaft mixer to make them moist, and then use mechanical vibration to extrude Press molding, under the pressure of 28Mpa, waste energy-saving lamps, waste residues and environmental protection bricks are made, and then the formed environmental protection bricks are transported to the autoclave for steam curing by a rail flat car via steel rails. The temperature is kept constant for 7 hours, and then the temperature is naturally cooled for 1.5 hours to make waste energy-saving lamp waste residue environmental protection brick products....

Embodiment 3

[0043] Get embodiment 1 discarded energy-saving lamp waste residue powder 50kg, calcium carbide waste residue powder 25kg, fly ash 35kg, Portland cement 16kg, particle diameter is the calcium oxide 15kg of 0.2mm, calcium sulfate 4kg, sodium carbonate 2kg, polycarboxylate Salt high-efficiency water reducer 0.5kg, sodium sulfate 0.8kg, calcium formate 0.5kg, Li polymer heavy metal collector 0.8kg and water 14kg, the above raw materials were mixed and stirred until wet, then extruded by mechanical vibration, at 30Mpa Lightweight hollow blocks made from waste energy-saving lamps and slag under pressure, and then the formed hollow blocks are sent from the rails to the autoclave for steam curing. First, the temperature is raised for 3 hours, and then the temperature is kept at 95-100 degrees for 6 hours. , and then cool down naturally for 2 hours to make lightweight hollow block products. After testing, the average compressive strength is: 8.0Mpa, the minimum value of a single block...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com