Mechanical navajoite roasting shaft kiln and roasting method

A roasting and vanadium ore technology, applied in the field of vanadium ore smelting, can solve the problems of waste of shaft kiln resources, failure to meet the requirements of energy saving and emission reduction, and high production costs, and achieve the effects of saving energy, improving resource utilization, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

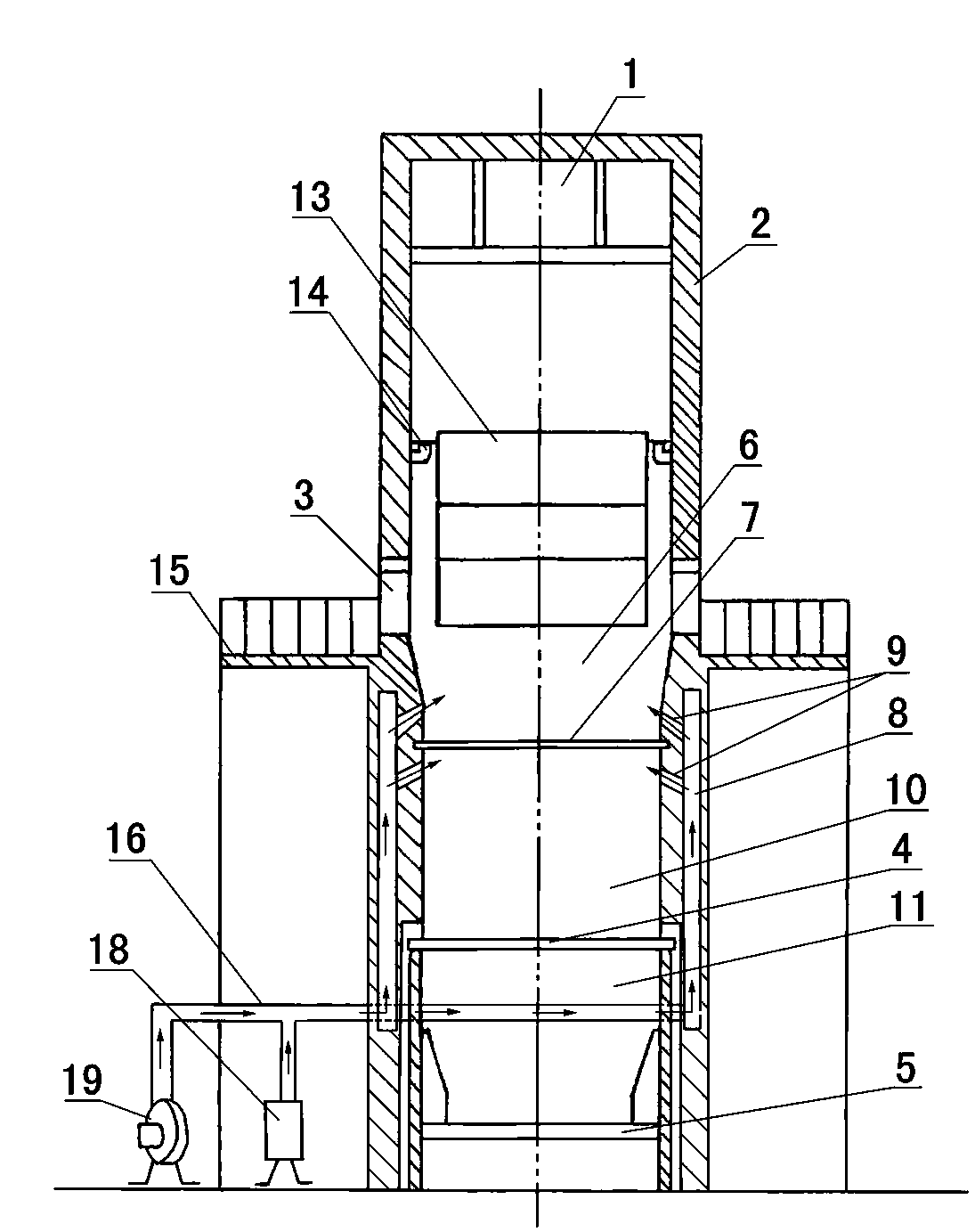

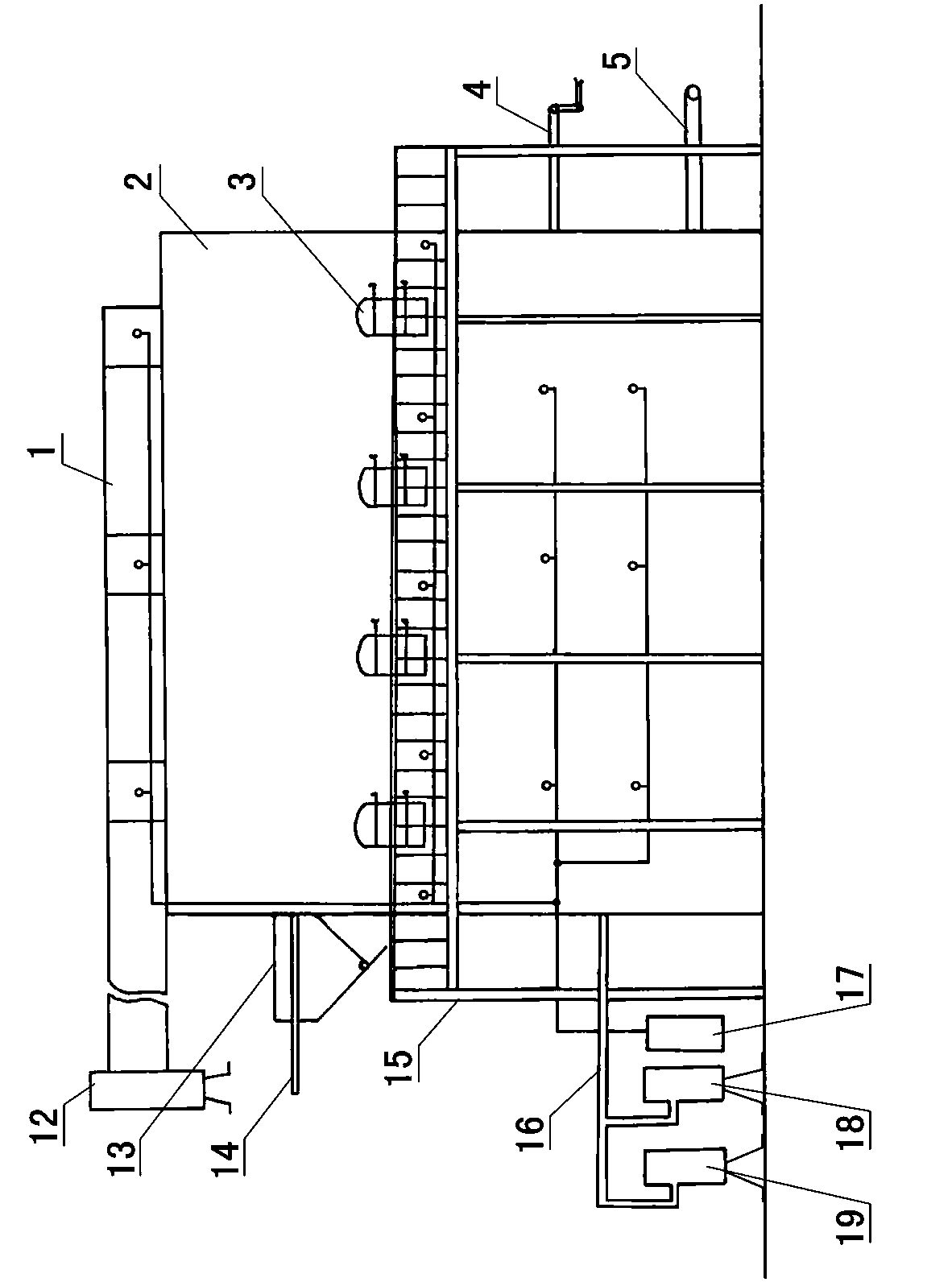

[0026] Examples see figure 1 , figure 2 As shown, this mechanized vanadium ore roasting shaft kiln includes a vertical kiln body 2 and a temperature monitoring system 17 for monitoring the kiln body 2. The top of the kiln body 2 is provided with a flue gas channel 1, and the flue gas channel 1 Connected with the induced draft fan 12, the temperature monitoring system 17 feeds back the temperature in the kiln body through sensors installed in various parts of the kiln body, and controls the wind speed and pressure of the induced draft fan 12 and the blower 19 to maintain a suitable firing temperature in the kiln.

[0027] The bottom of the kiln body 2 is provided with a discharge system 5 , an unloader 4 is provided above the discharge system 5 , and the inside of the kiln body between the unloader 4 and the discharge system 5 is a cooling chamber 11 . The unloading machine 4 is used to unload the roasted material in the roasting and heat preservation chamber into the cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com