Method for roasting tin-containing high-arsenic and high-sulfur material by fluidized rich oxygen

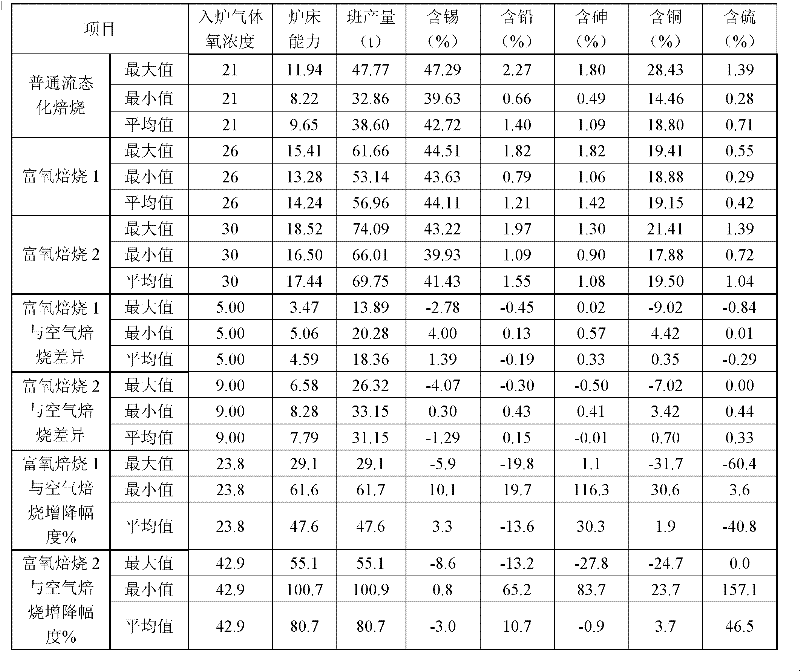

An oxygen-enriched roasting and fluidization technology, applied in the field of tin metallurgy, can solve the problems of low concentration and pollution of the environment, and achieve the effects of advanced technology, comprehensive recovery, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

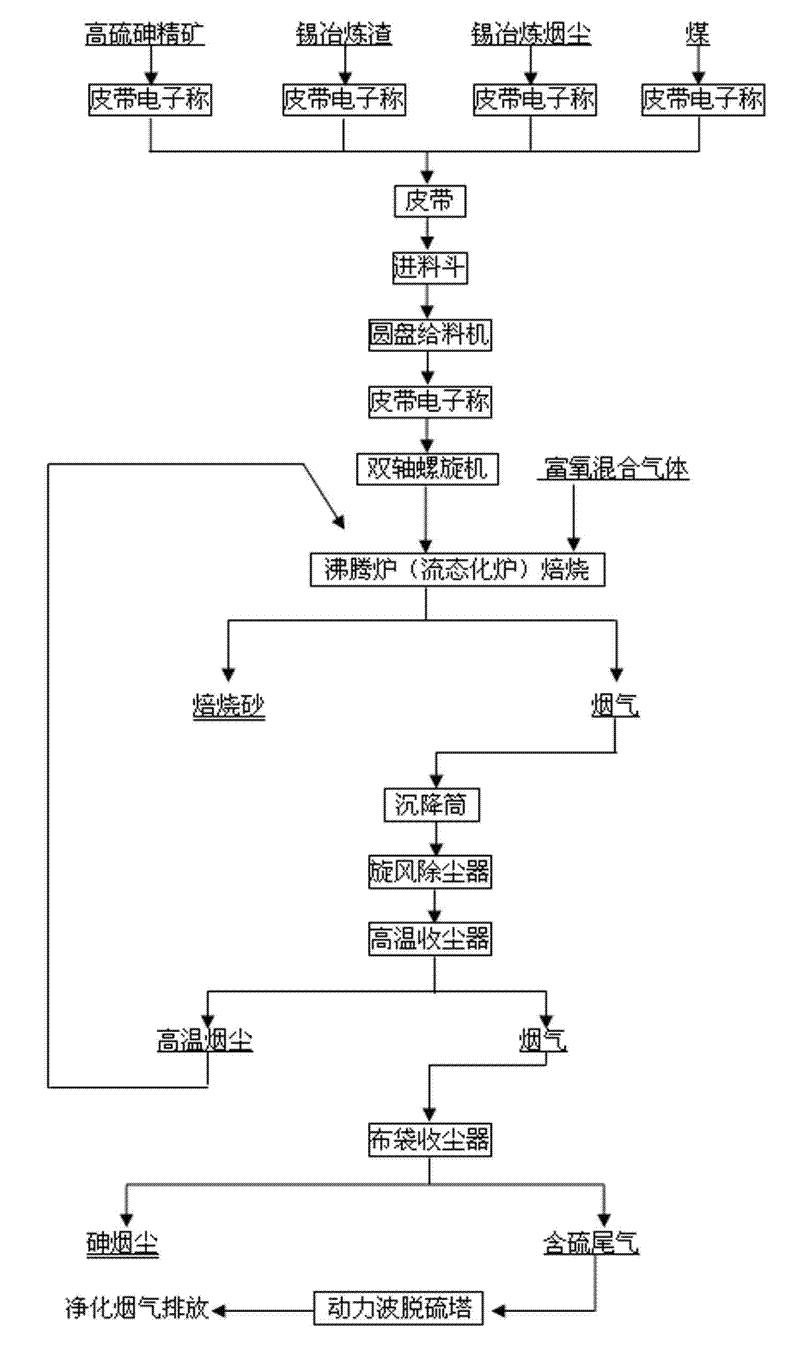

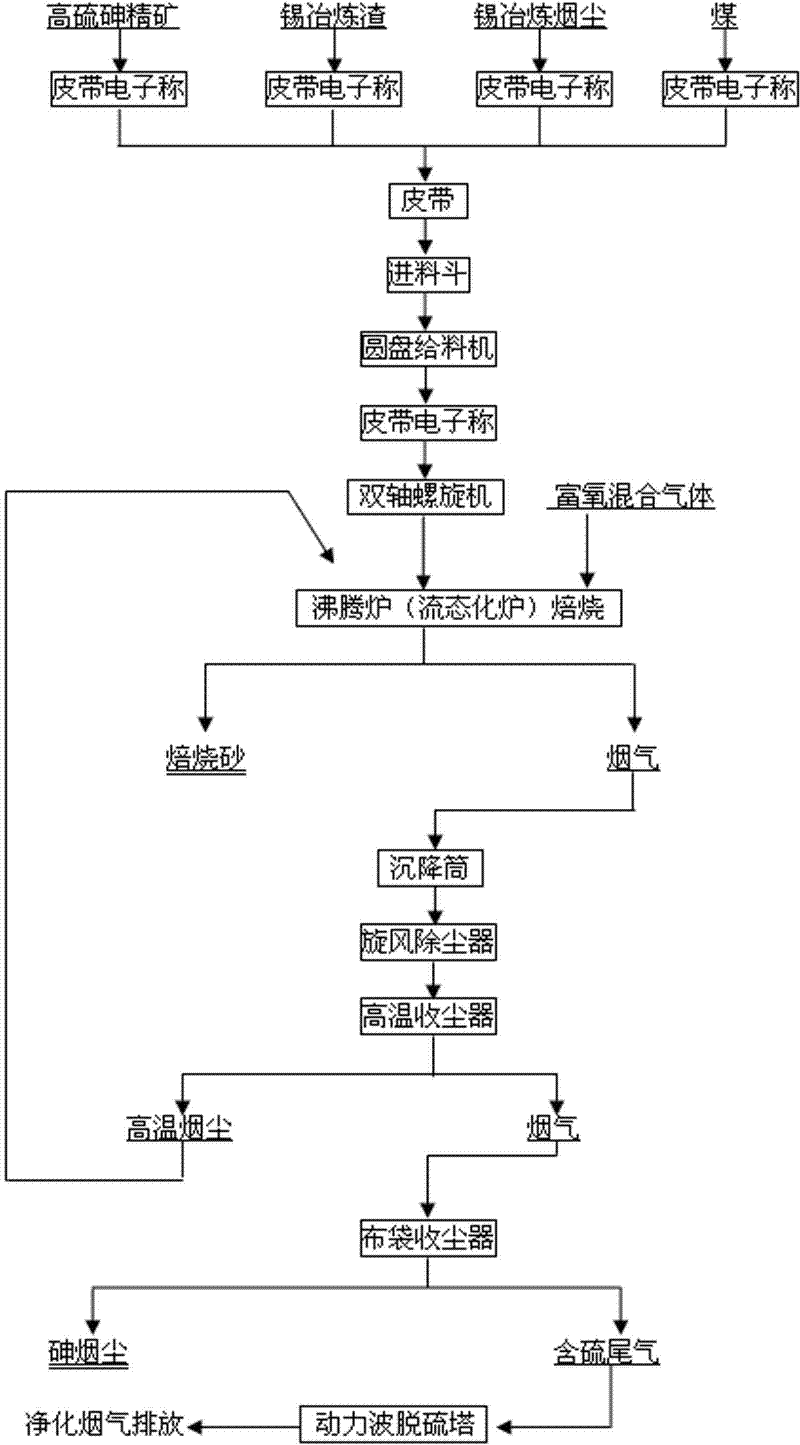

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are as follows:

[0019] 1. Turn on the DCS control system and connect the feeder and electronic belt scale of the fluidized furnace, the frequency conversion control circuit of the Roots blower, the regulating valve of the oxygen pipe, the emergency cut-off pneumatic valve, the various telecommunication and electronic control equipment related to the operation, the measurement Instruments such as temperature and pressure measurement are connected with the computer (operating console) in the operating room.

[0020] 2. Lay the bottom material well, put the firewood into the fluidized furnace, and distribute it evenly, and the amount does not exceed the overflow port.

[0021] 3. Light the firewood oven for 16 hours to 24 hours, and stop the firewood oven when the temperature of the furnace charge reaches 350°C to 400°C.

[0022] 4. After starting the exhaust gas treatment, ventilation, and dust collection systems in sequence, the DC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com