Hydrogen-nitrogen ratio control method for synthesis ammonia production device

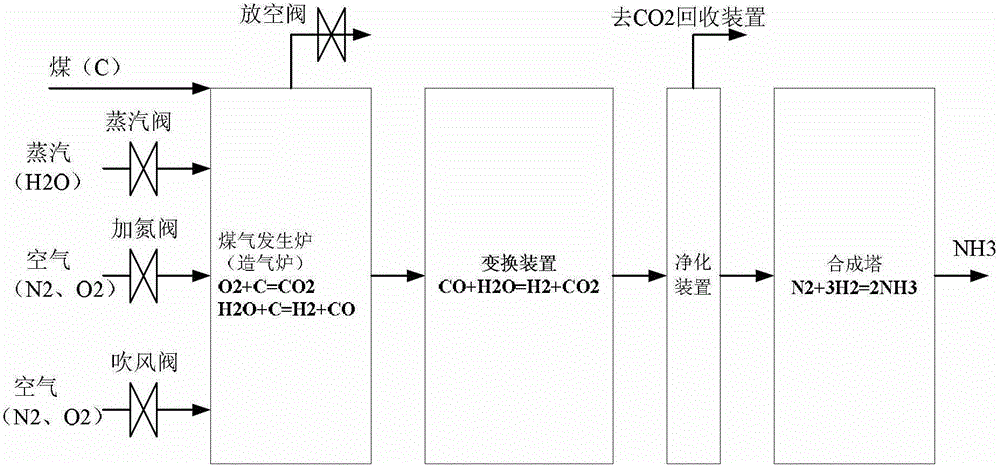

A production device and control method technology, applied in the direction of ammonia preparation/separation, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as deterioration of furnace conditions, unstable furnace conditions, and unstable hydrogen-nitrogen ratio. Achieve the effect of stable furnace condition and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

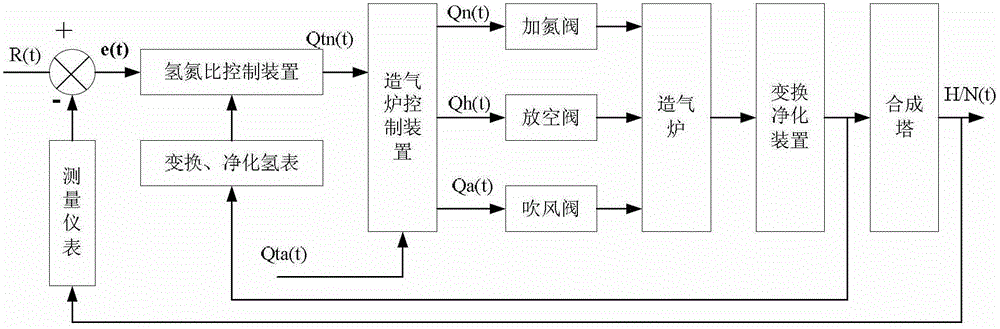

[0027] Embodiment 1 of the present invention provides a kind of synthetic ammonia production device, such as figure 2 As shown, it includes: hydrogen-nitrogen ratio control device, gas generator control device, nitrogen adding valve, vent valve, blowing valve, gas generator, conversion purification device, and synthesis tower. The specific production process is: the control device of the gas-making furnace receives the total nitrogen-added air quantity Qtn(t) output by the hydrogen-nitrogen ratio control device and the set value Qta(t) of the total air into the furnace, and generates nitrogen-added valve air into the furnace Quantity Qn(t), the amount of air discharged to the atmosphere into the furnace Qh(t) and the amount of air entering the furnace through the blowing valve Qa(t); Qn(t) passes through the nitrogen valve, Qh(t) passes through the vent valve, Qa(t) ) enters the gas-making furnace through the blowing valve, and after changing the purification device, it reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com