Anti-blocking device for coal falling region of coal-fired boiler

A technology for coal-fired boilers and regions, applied in the field of coal feeding of coal-fired boilers, can solve the problems of thinning wall thickness, increased coal blocking frequency, high labor intensity, etc., so as to reduce impact and wear, prolong service life, and reduce charging into the furnace. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

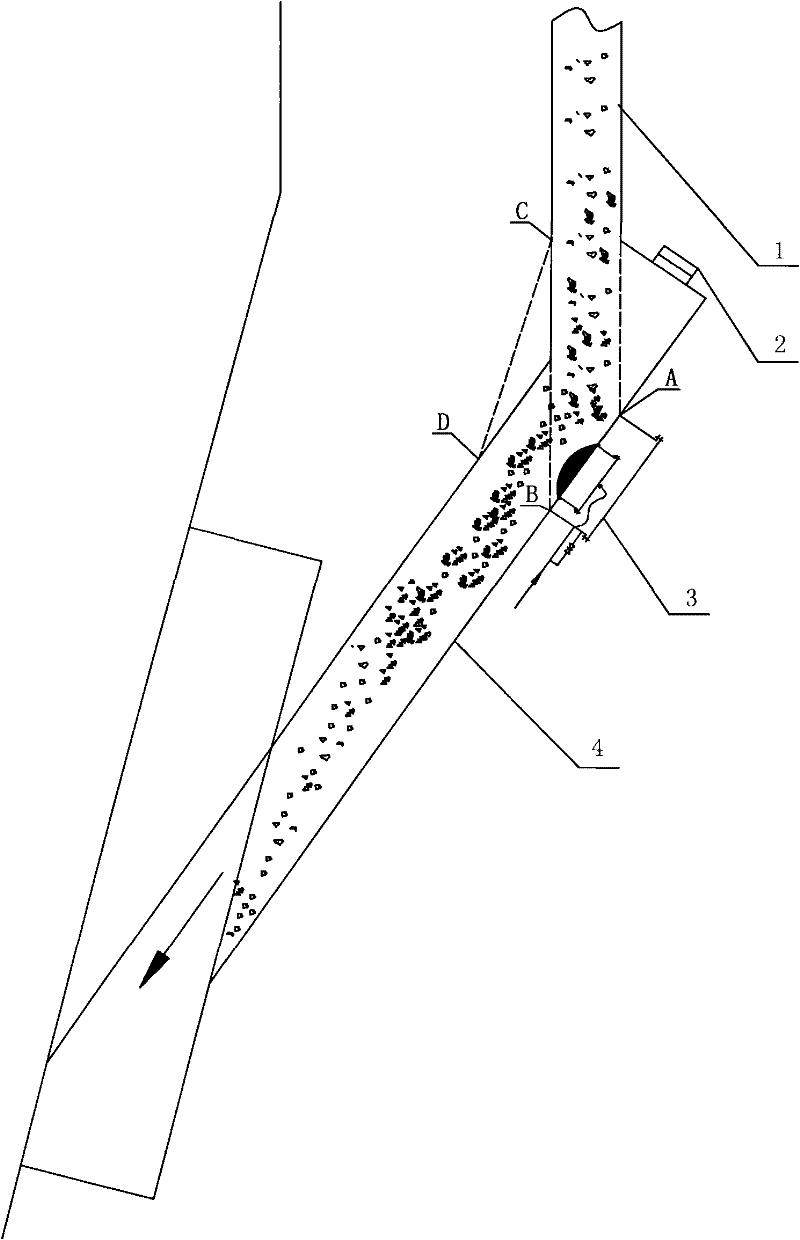

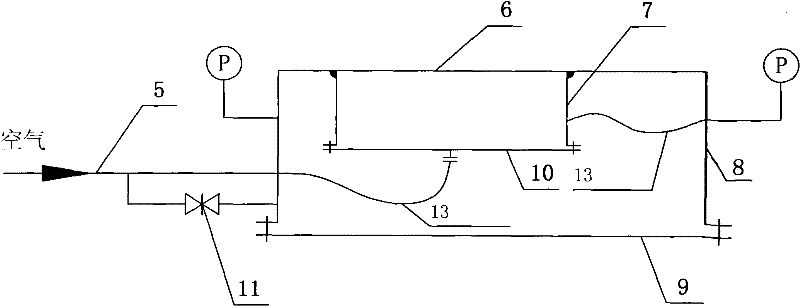

[0028] Draw a vertical line at both ends of the coal drop pipe 1, and pass the coal drop pipe 4 at two points A and B, that is, the coal drop area is A-B. A fluidization device is installed in this area, and the pressure to the inner air chamber is 0.1-0.3 Mpa, fluidizing air with a temperature of 90-260°C, the pressure is controlled to make the force exerted by the air on the particles equal to the gravity of the coal particles through the fluidization, so that the coal is in a suspended state, and the non-contact turning is realized in the coal falling area to prevent blockage Coal occurs.

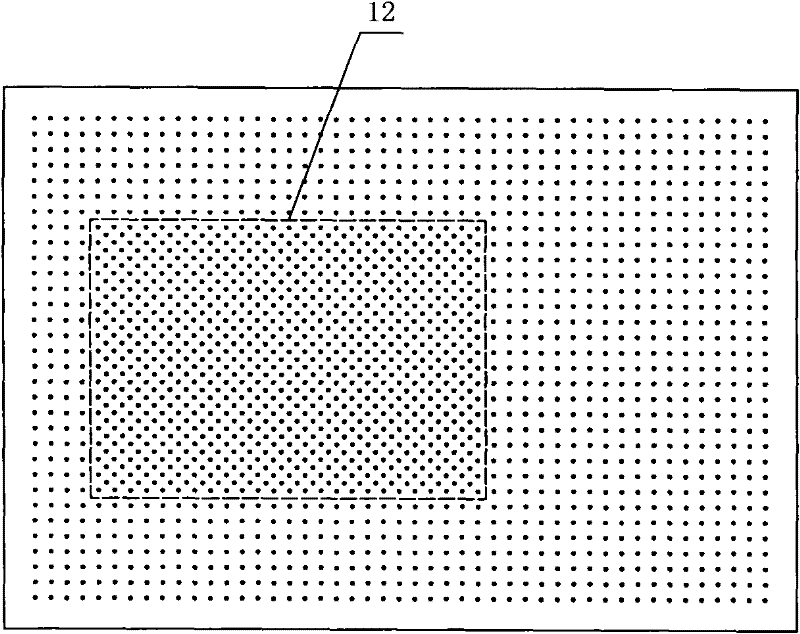

[0029] In addition, in order to avoid blockage of the small holes of the fluidized plate itself, the air chamber and the bottom plate in the present invention are connected by flanges, which can be disassembled for inspection and cleaning if necessary.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com