Double-blowing two-seat two-row vertical pellet-roasting furnace

A double-row, pelletizing technology, applied in shaft furnaces, furnaces, furnace types, etc., can solve the problems of increasing fan load, increasing resistance, and high maintenance costs, reducing fan load, strengthening heat exchange, and uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

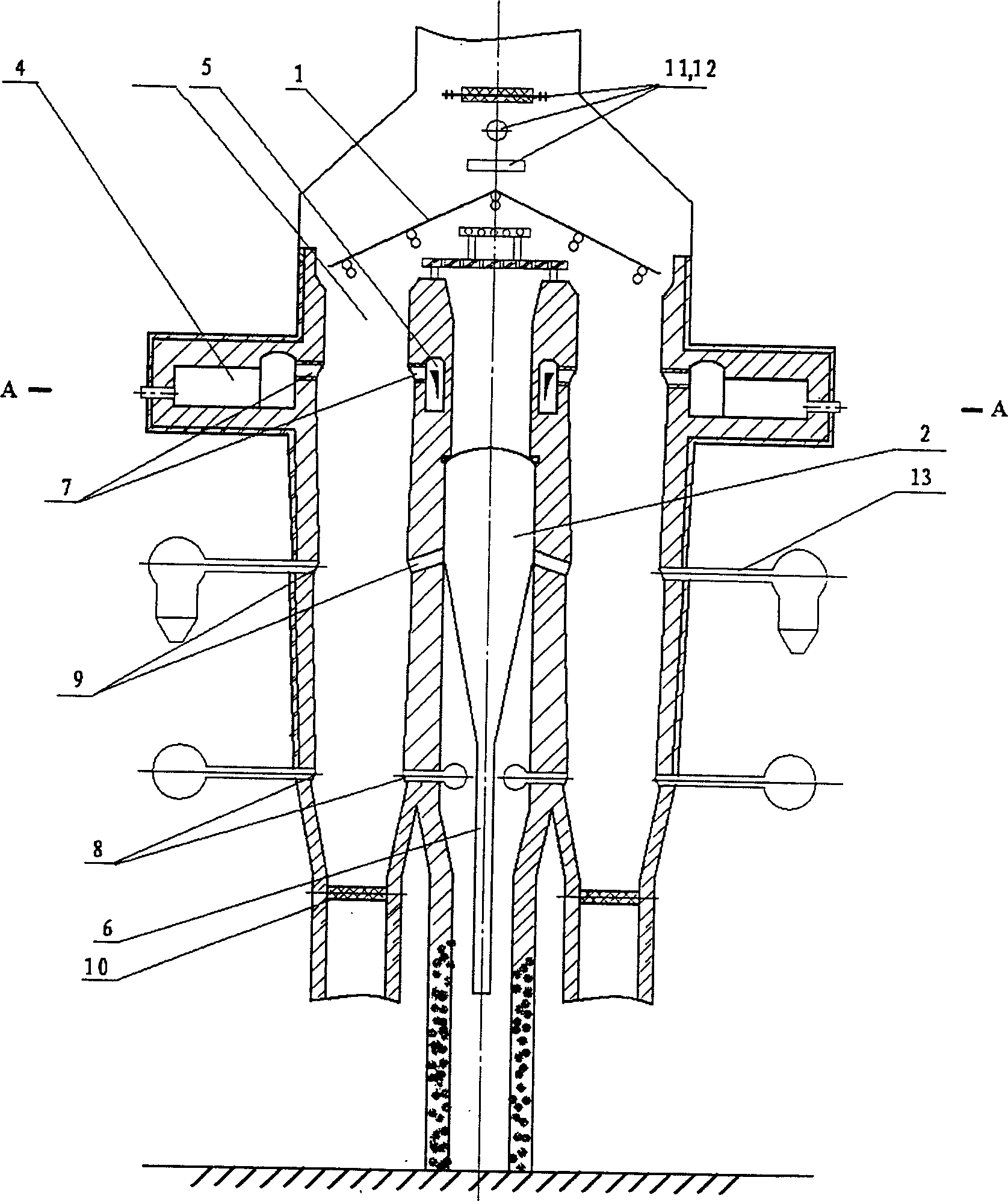

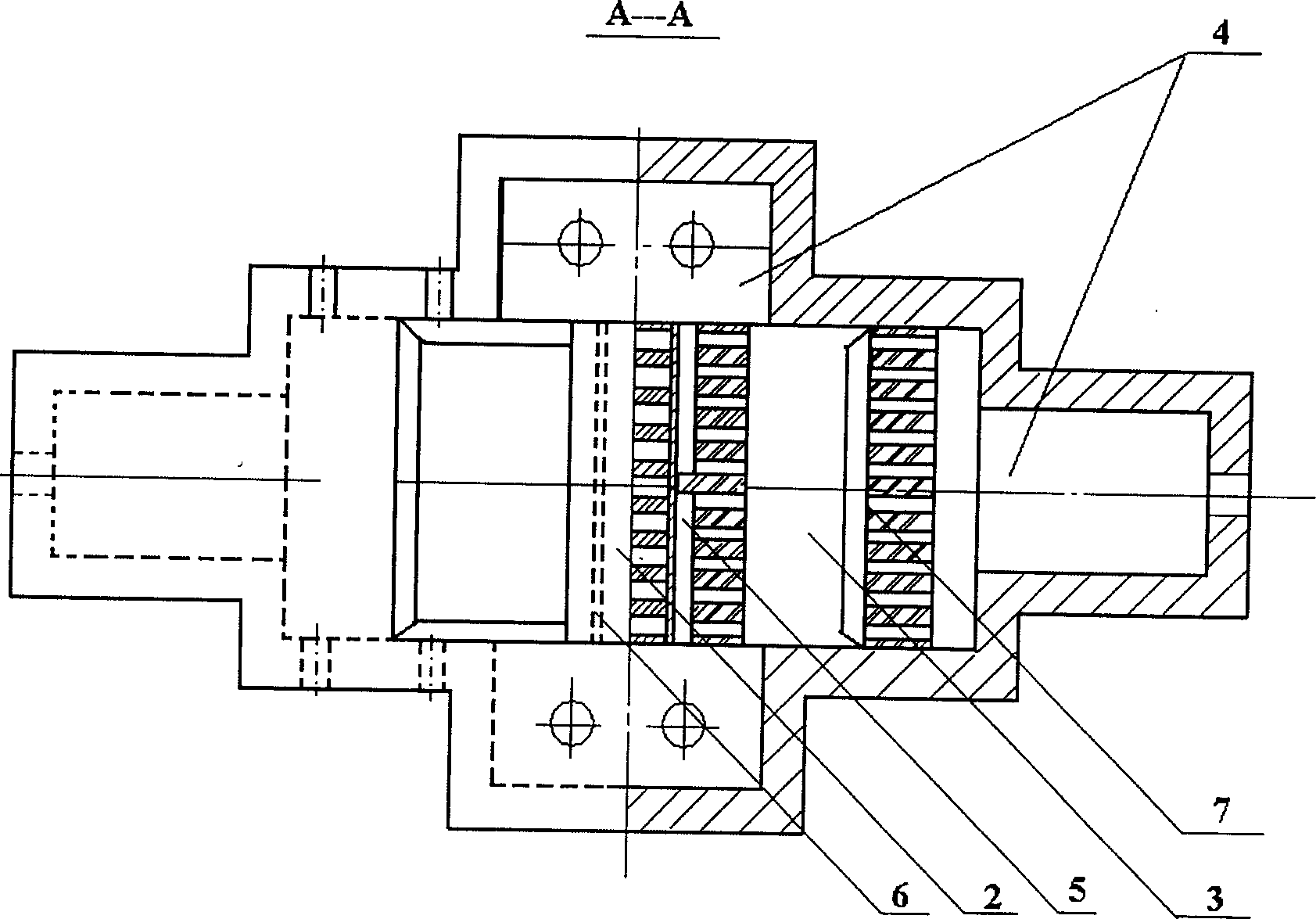

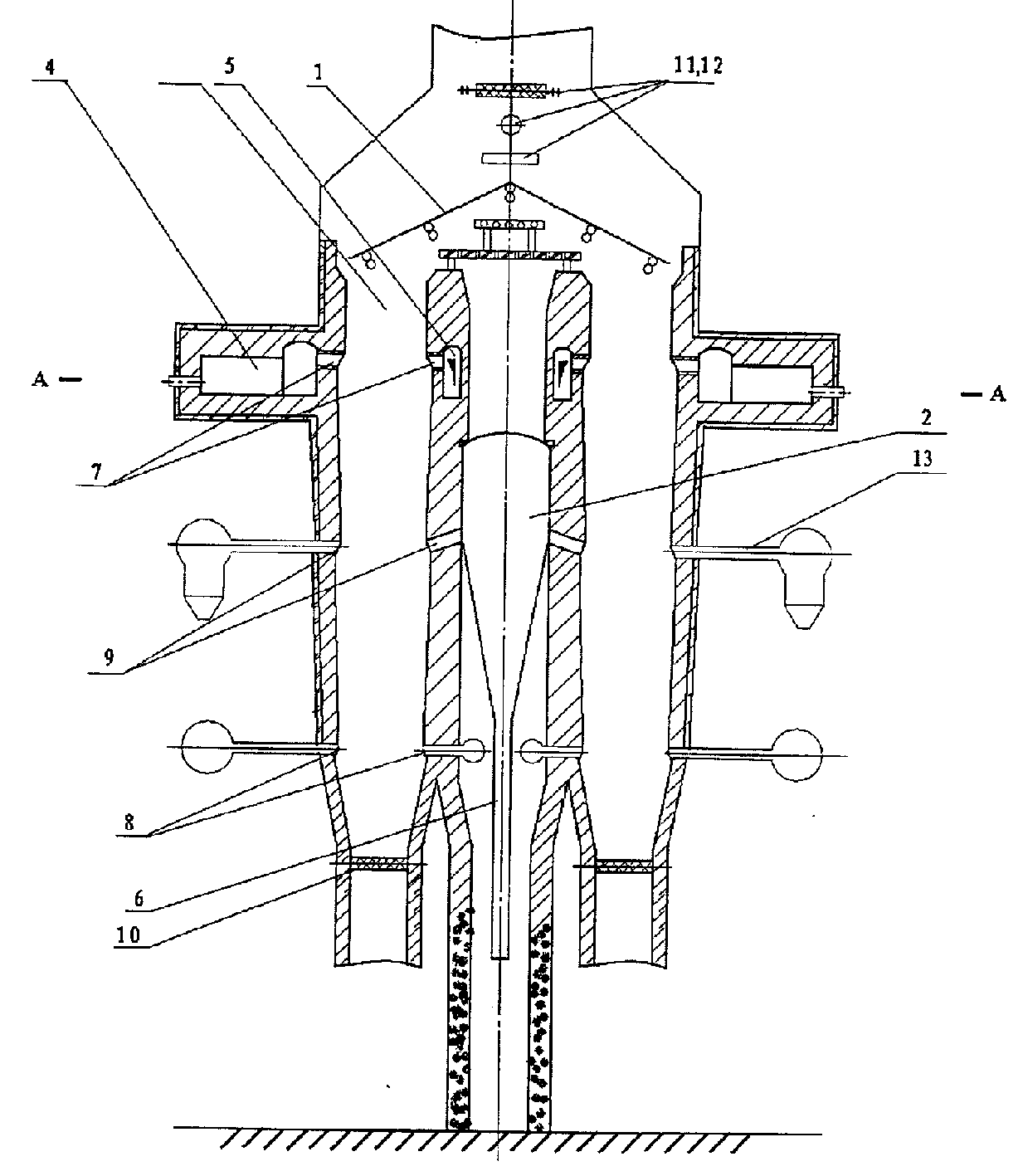

[0032] The structure of the present invention is as figure 1 Shown is a double-seat furnace type, that is, two shaft furnaces share one air guide chamber, and on both sides of the air guide chamber 2, there are roasting air distribution chamber 5, burner 7, exhaust air outlet 9 and cooling air outlet 10, and the air guide chamber 2 is respectively opened. The lower part of the air chamber 2 is the dust-reducing chamber 6, and six combustion chambers 4 are arranged on the four sides of the shaft furnace body 13, wherein the left and right two combustion chambers communicate with the burner 7 passages on the outside of the combustion chamber respectively, and the front and rear four combustion chambers respectively Connected with the roasting air distribution chamber 5 inside the combustion chamber, a discharge device 10 is provided at the lower part of the furnace wall 13 .

[0033] Use the present invention to refer to figure 1 , the Φ10-25mm iron-containing raw balls made by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com