Silicon carbide single crystal growth equipment with function of adjusting ratio of carbon to silicon in growth atmosphere

A silicon carbide single crystal, ratio adjustment technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve problems such as low silicon flow rate, low relative silicon content of silicon carbide powder, and carbonization of the growth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. It should be noted that the "semi-closed space" in the present document refers to a space that has no other places for gas to enter and exit except for the air holes and gas channels on the surface of the cover plate.

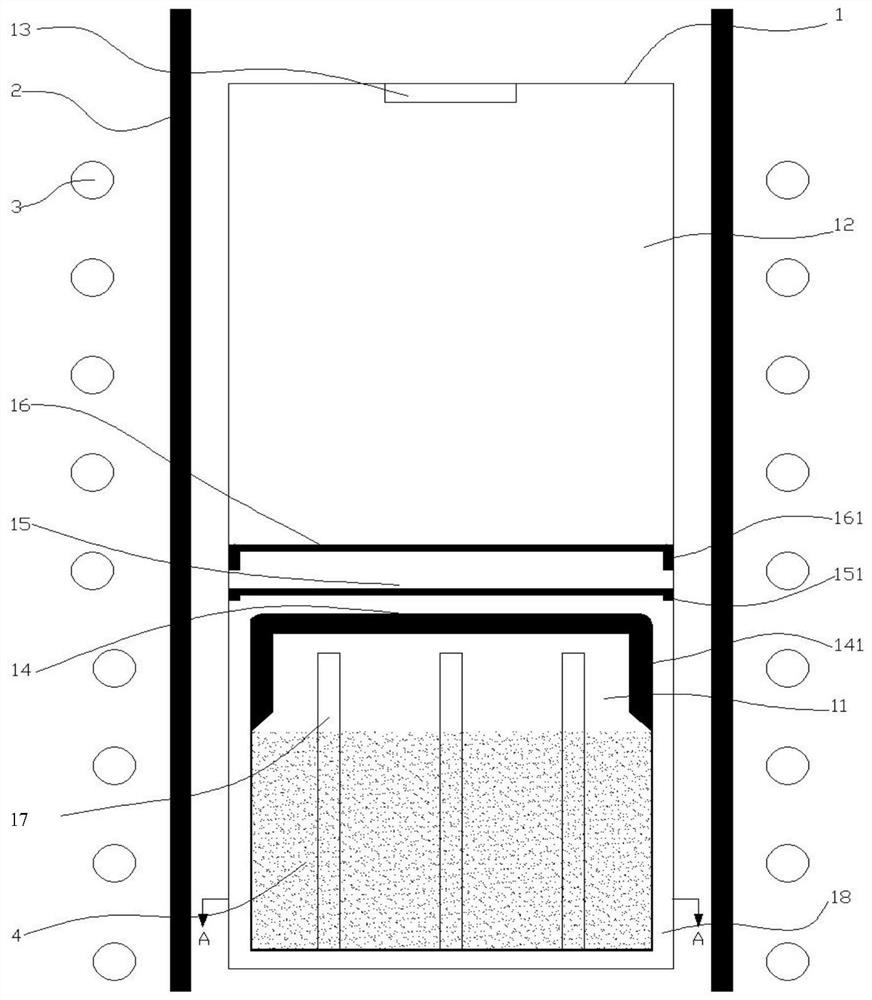

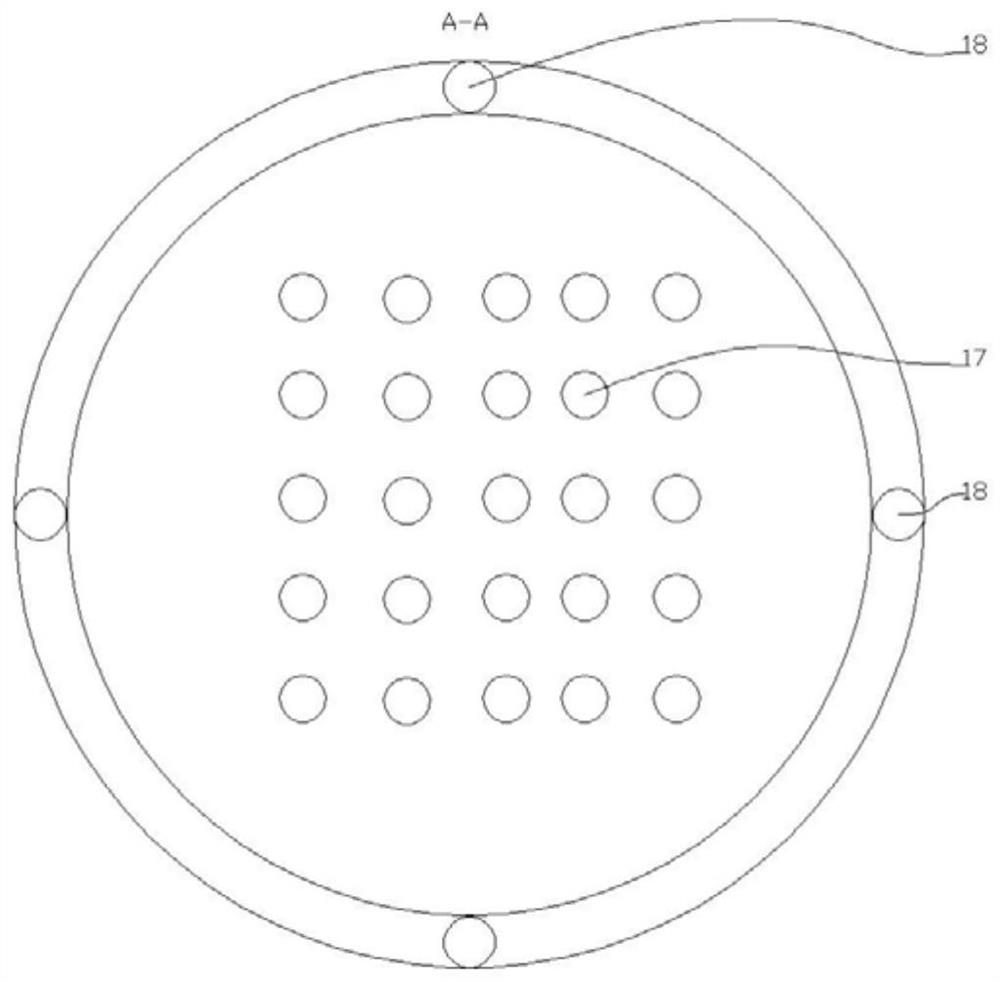

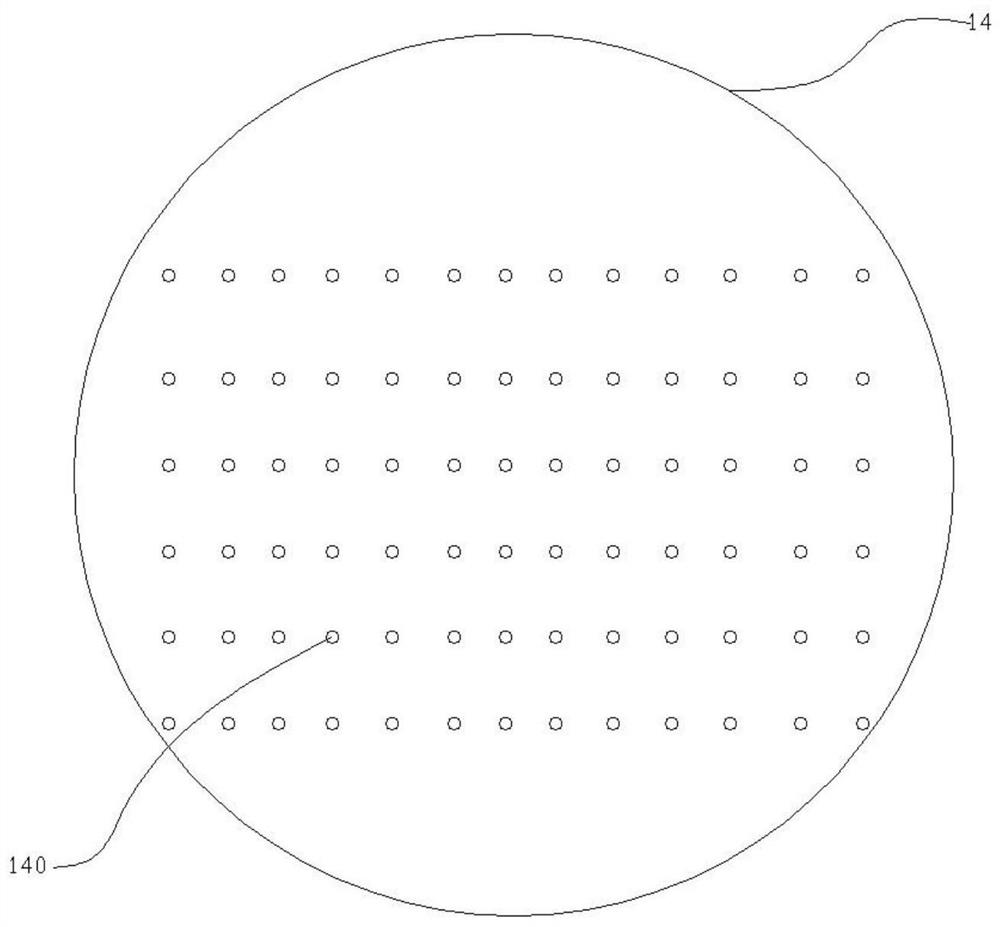

[0028] see figure 1 and figure 2 , a silicon carbide single crystal growth device with the function of adjusting the ratio of carbon to silicon in the growth atmosphere according to the present invention, comprising a quartz tube 2, an induction coil 3 and a graphite crucible 1, and the quartz tube and the heating coil are located at the bottom of the graphite crucible Externally, the graphite crucible 1 includes a silicon carbide powder heating zone 11, a growth chamber 12, and a seed crystal support 13. The gas sublimated by the heating of the silicon carbide powder heating zone enters the growth chamber, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com