Cement pool stirring device

A technology of mixing device and cement pool, which is applied to cement mixing device, clay preparation device, chemical instrument and method, etc., can solve the problems of low work efficiency and insufficient mixing, so as to improve mixing effect, improve product quality, and maintain cleanliness. and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

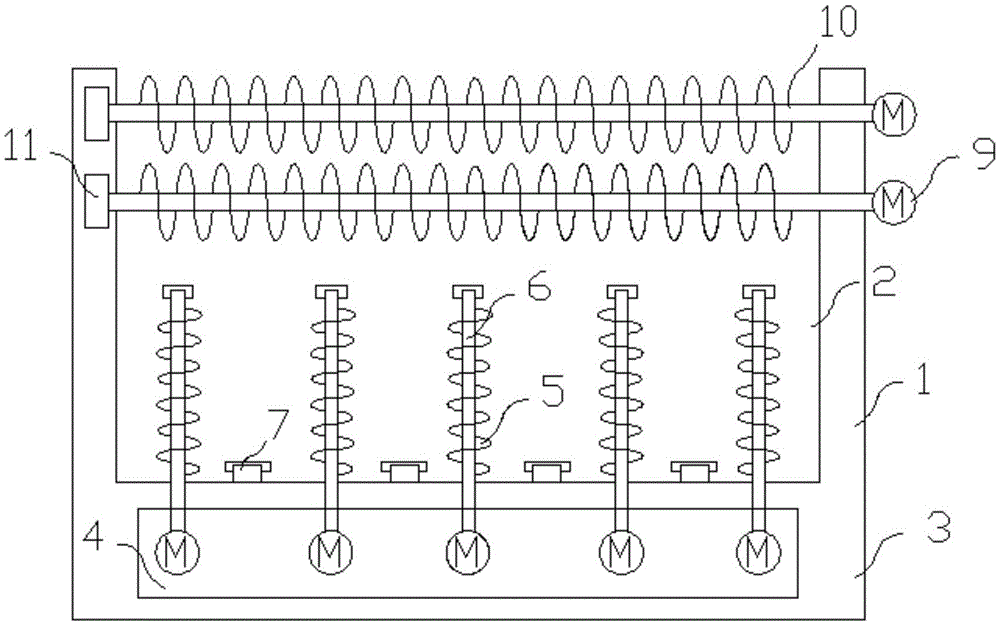

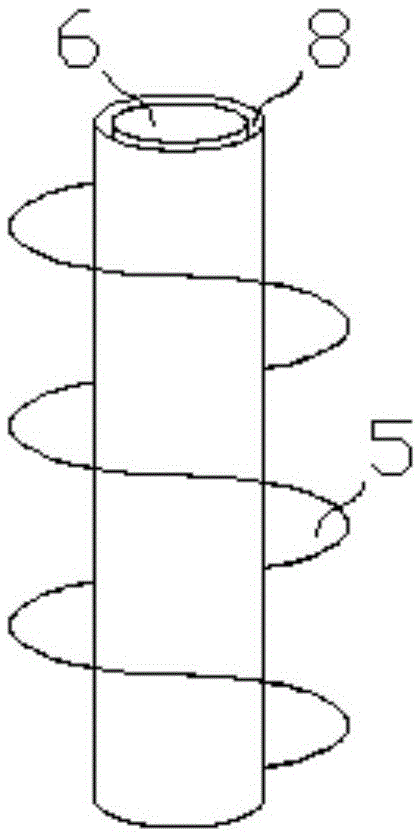

[0016] This embodiment provides a cement pool stirring device, such as Figure 1-2 As shown, it includes a stirring tank 1, a stirring tank 2 and a bottom tank 3. The stirring tank 1 is composed of a stirring tank 2 and a bottom tank 3. The inner surface of the bottom of the stirring tank 2 is provided with a number of water injection holes 7, and the inside of the stirring tank 2 is vertically arranged. There are a number of vertical stirring columns 6, the top of the vertical stirring column 6 is provided with a horizontal stirring column 10, the cylinder surfaces of the vertical stirring column 6 and the horizontal stirring column 10 are equipped with stirring blades 5, and the inside of the bottom tank 3 is equipped with a servo motor 4 , the bottom of the longitudinal stirring column 6 passes through the stirring tank 2 and is connected to the servo motor 4 , and one end of the horizontal stirring column 10 passes through the stirring tank 2 and is connected to a motor 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com