Regenerative precoated sand roasting furnace preheating system

A technology of roasting furnace and coated sand, which is applied in the directions of preheating cost, furnace and charge, etc., can solve the problems of low air, heat loss of the roasting furnace, and increase the energy consumption of the roasting furnace, so as to reduce the usage and reduce the heat consumption. , Improve the effect of preheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

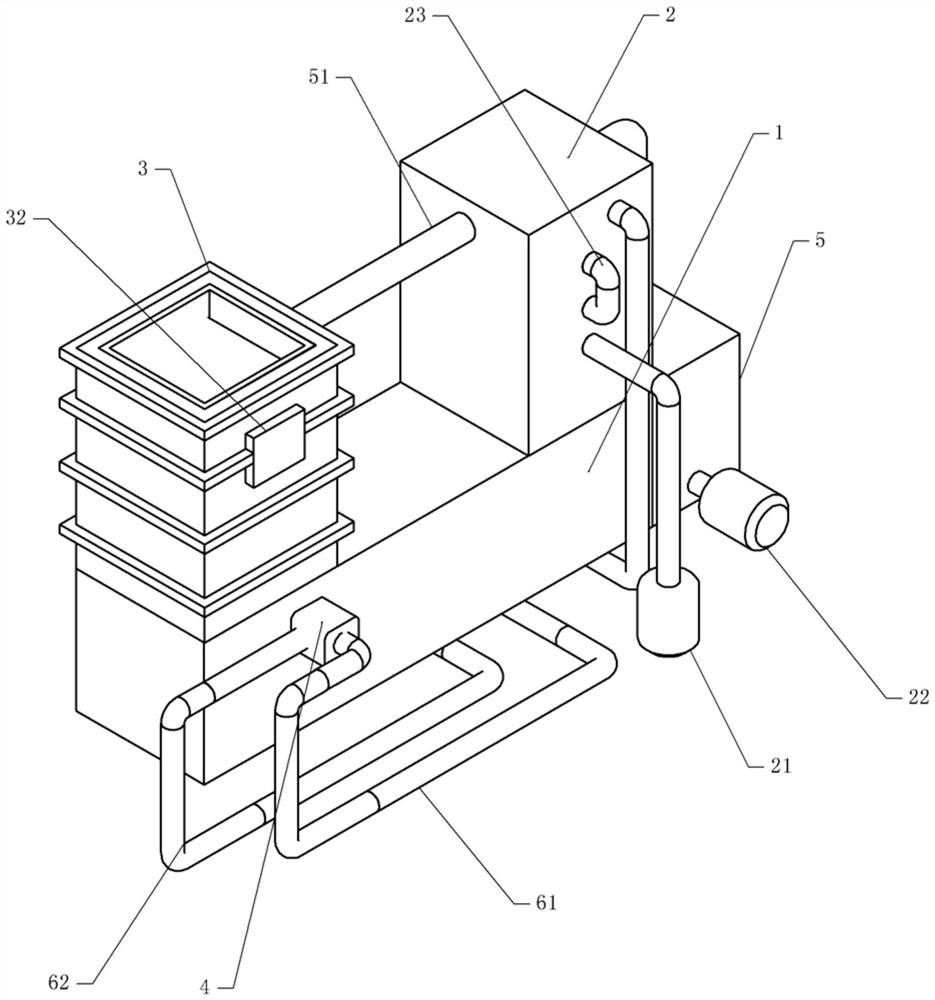

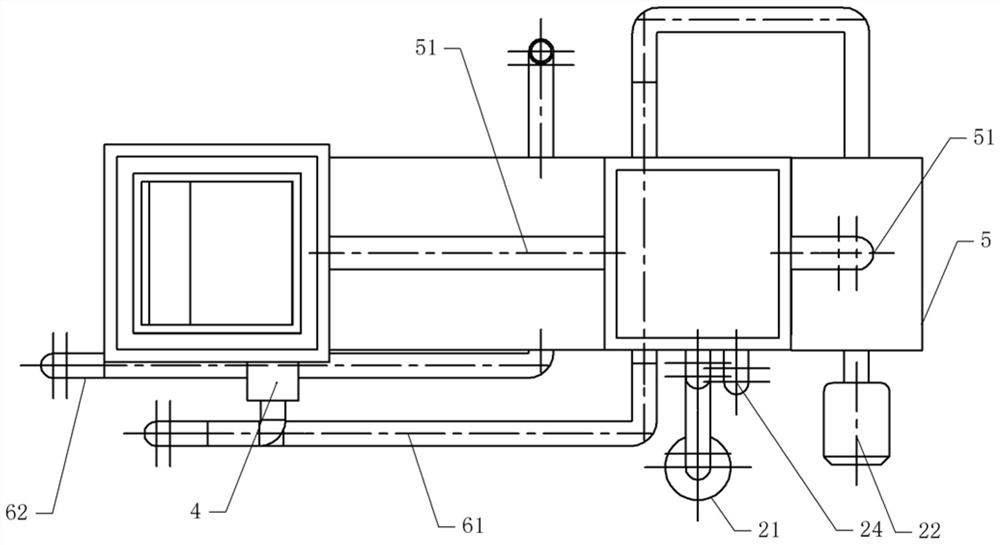

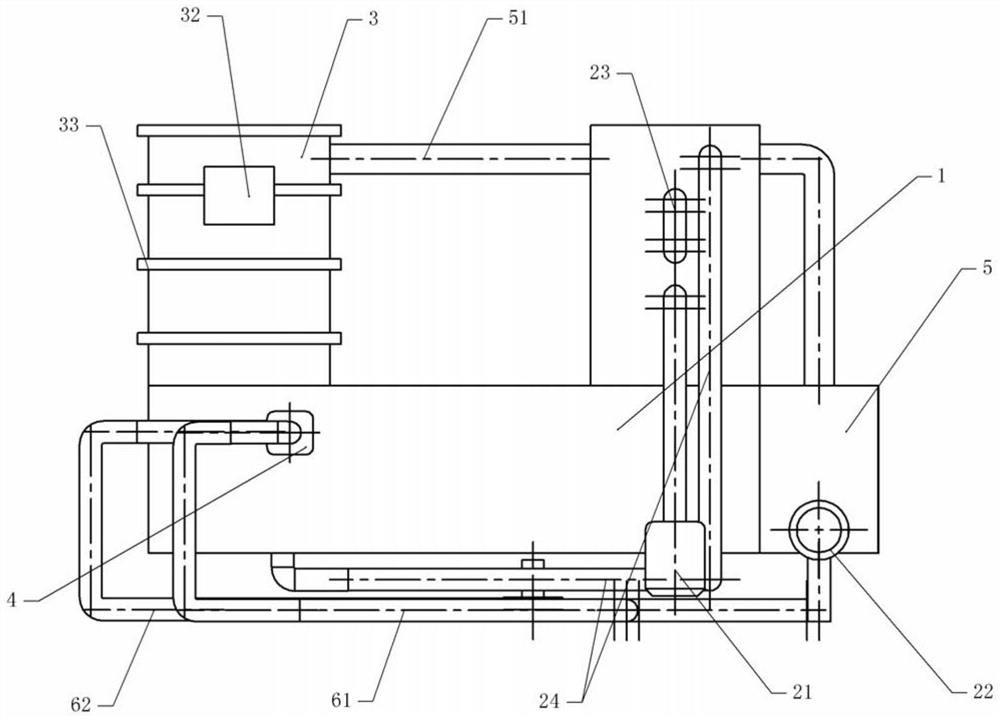

[0036] Basic as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 5 Shown: a regenerative coated sand roasting furnace preheating system, including a feed chamber 3, a preheating chamber 2 and a preheating bag 5. Feeding chamber 3, preheating chamber 2 and preheating bag 5 are all installed on the roasting furnace 1 in the present embodiment.

[0037] In this embodiment, the upper and lower parts of the feeding chamber 3 are provided with openings, and the side walls of both sides in the feeding chamber 3 are fixed with several feeding plates 31 by bolts, and the feeding plates 31 on both sides are along the feeding The longitudinal direction of the chamber 3 is arranged in a staggered manner, and the feeding plate 31 is obliquely facing the middle of the feeding chamber 3, and the arrangement of the feeding plate 31 can form a deflector channel for sand particles to pass through. The outer side wall of the feed chamber 3...

Embodiment 2

[0050] The difference between embodiment two and embodiment one is that, as attached Figure 6 And attached Figure 7 As shown, there is a cavity 311 in the feed plate 31, and the cavity 311 is communicated with a number of air holes 312 uniformly distributed on the feed plate 31. Air plates 313 are arranged in the air holes 312, and the air plates 313 are arranged obliquely. The end of 313 near the upper surface of feed plate 31 is higher than the end of gas plate 313 away from the upper surface of feed plate 31, the bottom of gas plate 313 is provided with return spring 314, and one end of return spring 314 is fixed on the feed plate 31, resets The other end of the spring 314 is fixed on the air plate 313, and the air plate 313 has some air holes, and the diameter of the air holes is smaller than the diameter of the sand grains. The cavity 311 is communicated with a hose, and the hose is communicated with an air pump.

[0051] The specific implementation process is as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com