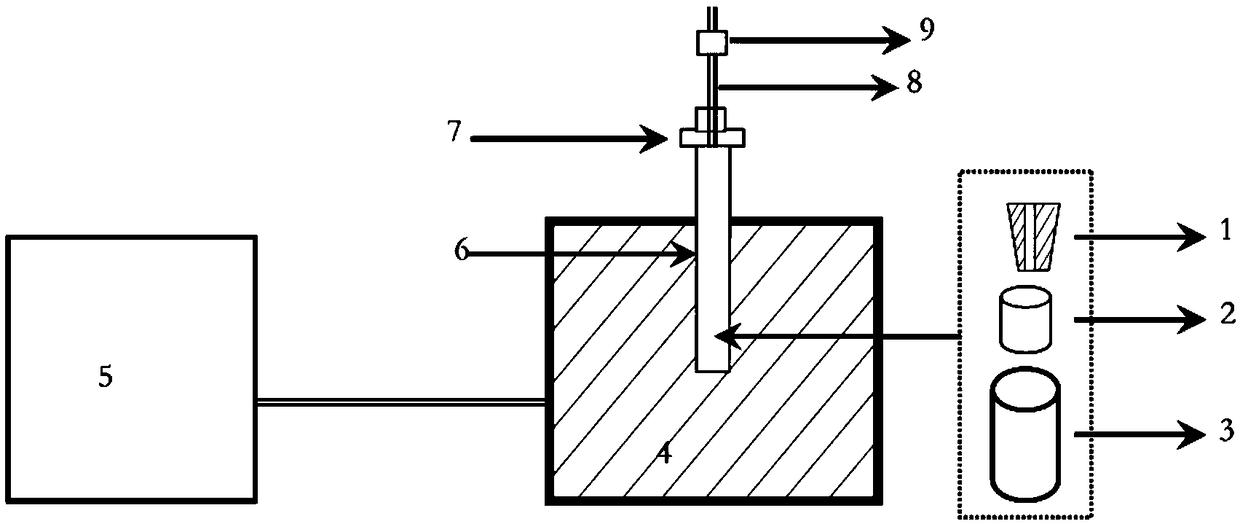

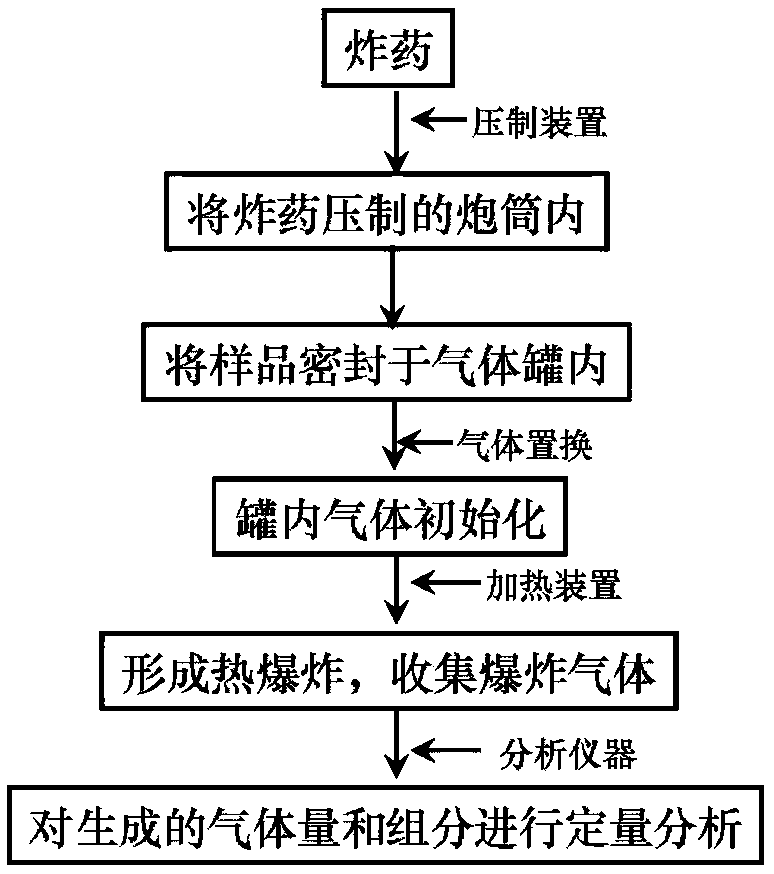

Small-charge thermal explosion gas collecting device and gas analysis method

A collection device and gas analysis technology, which is applied in measurement devices, analytical materials, sampling devices, etc., and can solve problems such as difficulty in obtaining samples, large doses of drugs, and gas interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 10 mg of HMX elemental explosive and place it in the base, plug it into the plug, and place it in the barrel, use a pressurizing device to pressurize 0.25MPa, fix the plug in the base, and seal the sample inside the barrel. Then place the gun barrel inside the gas tank, seal the gas tank, replace the gas inside the gas tank by vacuuming and gas replacement, and set the initial atmosphere before the thermal explosion of the explosive according to requirements. Place the gas collection tank containing the sample in Wood's metal heated to the specified temperature (330°C), take out the gas collection tank after hearing the explosion, and cool it to room temperature. Connect the gas collection tank to the gas chromatograph, measure the gas pressure (132.15KPa) in the gas collection tank, and calculate the volume of the gas generated by the thermal explosion of the HMX simple substance explosive according to the rational gas state equation (580L, standard condition, thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com