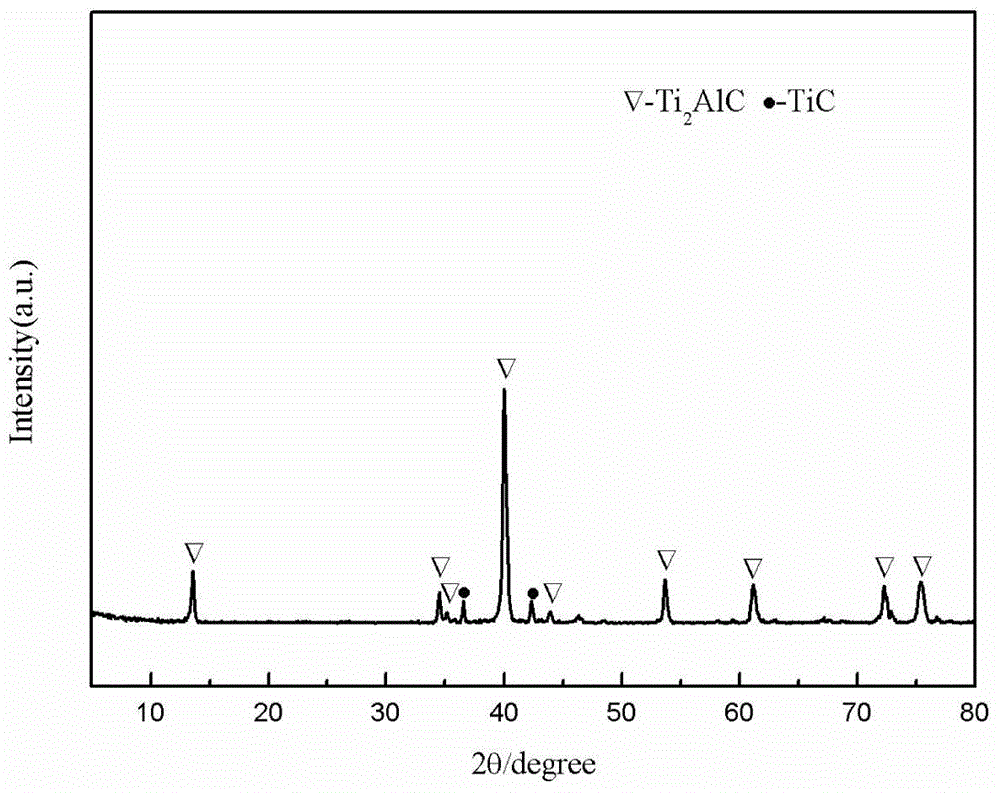

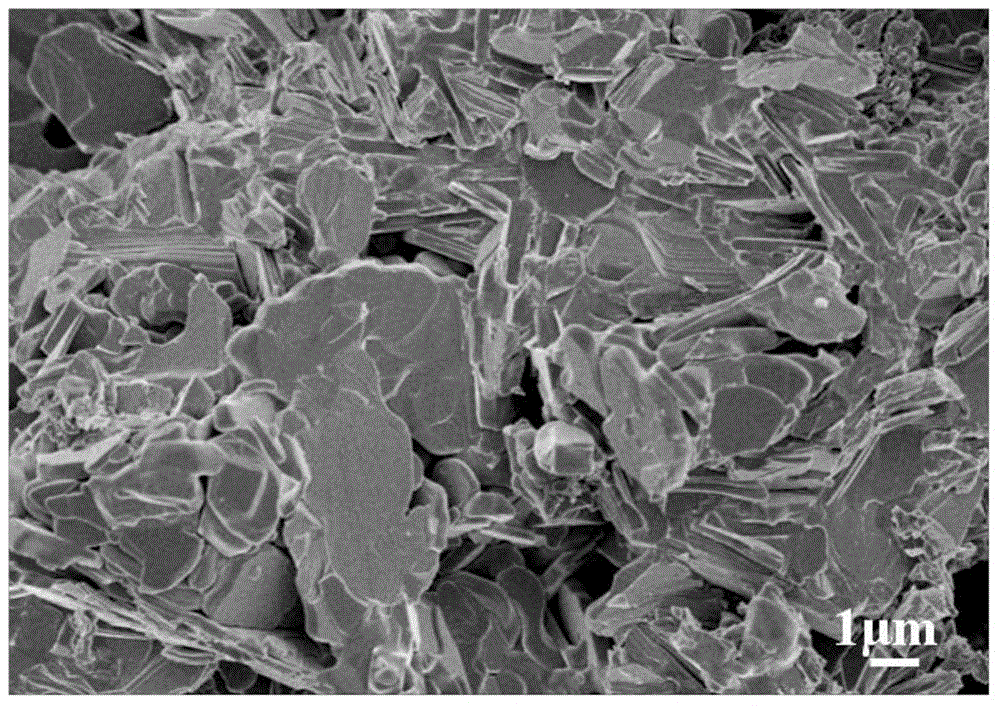

Method for preparing Ti2AlC ceramic material at low temperature

A ceramic material and low-temperature technology, applied in the field of preparation of ternary layered ceramic materials, can solve the problems of unfavorable production of AlC ceramic materials, high sintering temperature, expensive equipment, etc., and achieve the effect of short preparation time, high purity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Use Ti powder, Al powder and TiC powder as raw materials, weigh them according to their molar ratio of 1.00:1.00:1.00, then put the mixed powder into a ball mill jar, use alcohol as the ball mill medium, Ball milling for 4 hours at a ratio of 4:1 and a rotational speed of 400 rpm, and vacuum-dry the ground powder at 60°C for 2 hours to obtain a uniformly mixed powder;

[0021] Step 2: Put the mixed powder prepared in Step 1 into a stainless steel mold with an inner diameter of 10 mm, and cold press it into a round block with a thickness of 2 mm under a uniaxial pressure of 200 MPa;

[0022] Step 3: Put the pre-pressed block obtained in Step 2 into an air furnace at a temperature of 850°C for thermal explosion reaction, keep it warm for 1 minute, take it out of the air furnace, cool it to room temperature, and grind off the oxide layer on its surface ;

[0023] Step 4: Break the block obtained in Step 3 and ball mill it into powder by dry milling. The ball-to-ma...

Embodiment 2

[0025] Step 1: Use Ti powder, Al powder and TiC powder as raw materials, weigh them according to their molar ratio of 1.05:1.10:1.00, then put the mixed powder into a ball mill jar, use alcohol as the ball mill medium, Ball milling for 4 hours at a ratio of 4:1 and a rotational speed of 400 rpm, and vacuum-dry the milled powder at 60°C for 6 hours to obtain a uniformly mixed powder;

[0026] Step 2: Put the mixed powder prepared in Step 1 into a stainless steel mold with an inner diameter of 10 mm, and cold press it into a round block with a thickness of 8 mm under a uniaxial pressure of 500 MPa;

[0027] Step 3: Put the pre-pressed block obtained in Step 2 into an air furnace at a temperature of 780°C for thermal explosion reaction, take it out of the air furnace after keeping it warm for 5 minutes, and grind off the oxide layer on the surface after cooling to room temperature ;

[0028] Step 4: Break the block obtained in Step 3 and ball mill it into powder by dry milling. ...

Embodiment 3

[0030] Step 1: Use Ti powder, Al powder and TiC powder as raw materials, weigh them according to their molar ratio of 1.25:1.30:1.00, then put the mixed powder into a ball mill jar, use alcohol as the ball mill medium, Ball milling for 4 hours at a ratio of 4:1 and a rotational speed of 400 rpm, and vacuum-dry the milled powder at 60°C for 4 hours to obtain a uniformly mixed powder;

[0031] Step 2: Put the mixed powder obtained in Step 1 into a stainless steel mold with an inner diameter of 10 mm, and cold press it into a round block with a thickness of 4 mm under a uniaxial pressure of 50 MPa;

[0032] Step 3: Put the pre-pressed block obtained in Step 2 into an air furnace at a temperature of 700°C for thermal explosion reaction, keep it warm for 2 minutes, take it out of the air furnace, cool it to room temperature, and grind off the oxide layer on its surface ;

[0033] Step 4: Break the block obtained in Step 3 and ball mill it into powder by dry milling. The ball-to-ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com