Device and method for preparing high-purity ammonia by regeneration of ammonia-contained tail gas of electronic industry

A technology for the electronics industry and high-purity ammonia, applied in the preparation/separation of ammonia, hydrogen production, chemical industry, etc., can solve the problems of decomposition method consumption, multi-energy, etc., to overcome the easy poisoning of catalysts, reduce production costs, reduce Effect of pressure and temperature conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

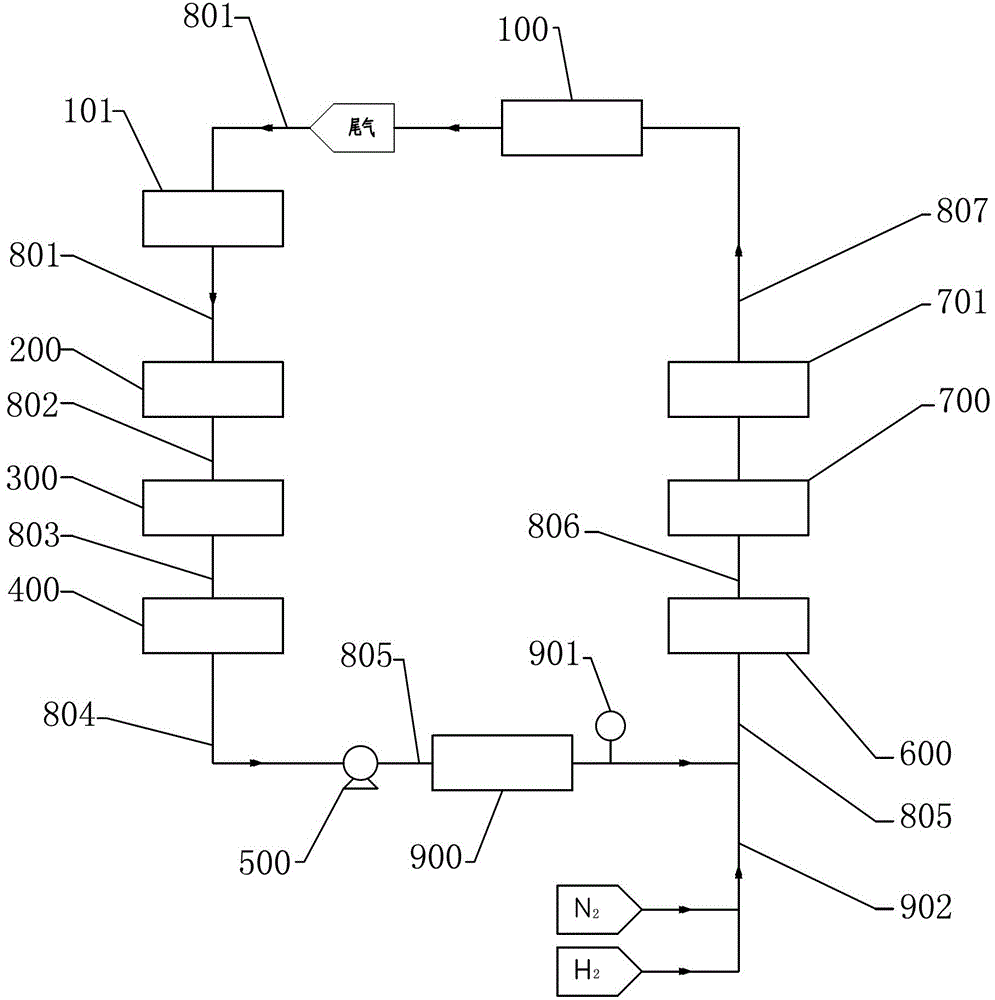

[0075] see figure 1 As shown, a device for preparing high-purity ammonia by regeneration of ammonia-containing tail gas in the electronics industry includes a nitride reactor 100, a filter 200, an ammonia decomposition device 300, a first purifier 400, a booster pump 500, and a second purification Device 600 and high-purity ammonia synthesis device 700;

[0076] The nitrogen compound reactor 100 is connected with the filter 200 through the first pipeline 801, the filter 200 is connected with the ammonia decomposing device 300 through the second pipeline 802, and the ammonia decomposing device 300 is connected with the first purifying device 300 through the third pipeline 803 The first purifier 100 is connected with the booster pump 500 through the fourth pipeline 804, and the booster pump 500 is connected with the second purifier 600 through the fifth pipeline 805, and the second purifier 600 is connected through The sixth pipeline 806 is connected to the high-purity ammonia ...

Embodiment 2

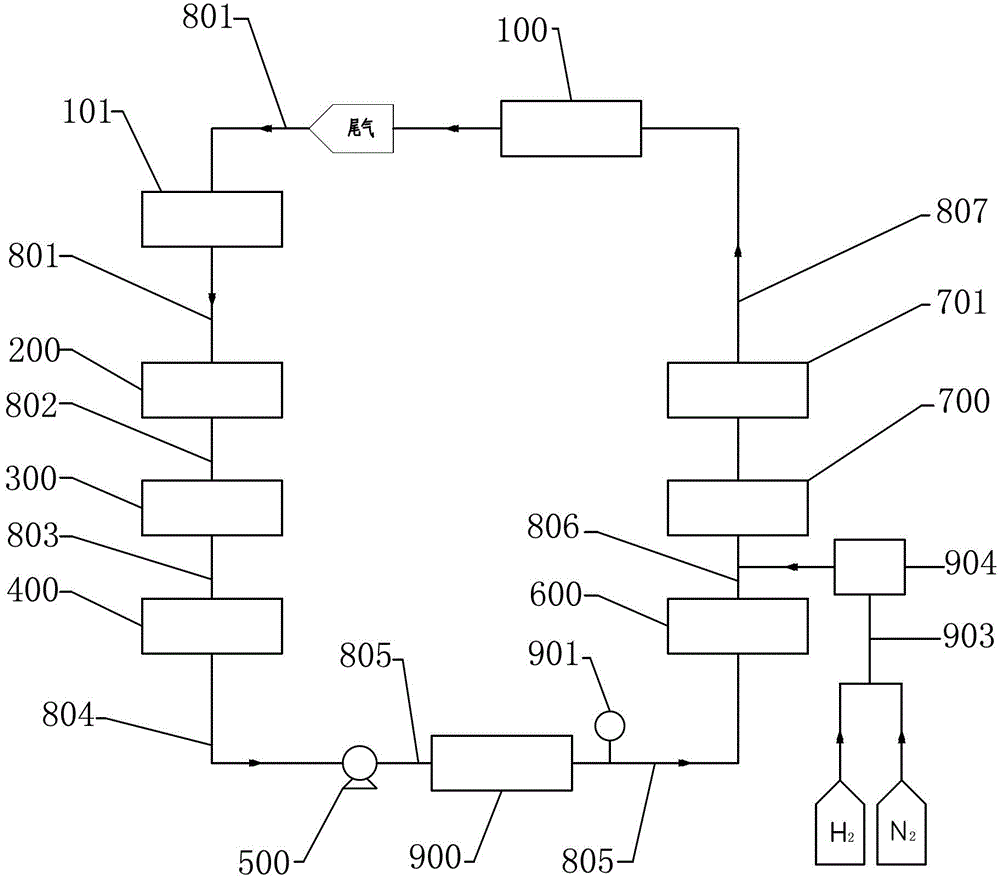

[0080] see figure 2 As shown, repeat Example 1, the difference is that the first hydrogen-nitrogen supplementary adding pipe 902 is not set between the hydrogen-nitrogen ratio real-time monitoring device 901 and the second purifier 600 as the first hydrogen-nitrogen ratio adjustment device; and On the sixth pipeline 806 connecting the second purifier 600 and the high-purity ammonia synthesis device 700, a second hydrogen and nitrogen supplementary feeding pipe 903 is connected as a second hydrogen and nitrogen ratio adjustment device, and the second hydrogen and nitrogen supplementary feeding pipe 903 is provided with a third purifier 904 .

Embodiment 3

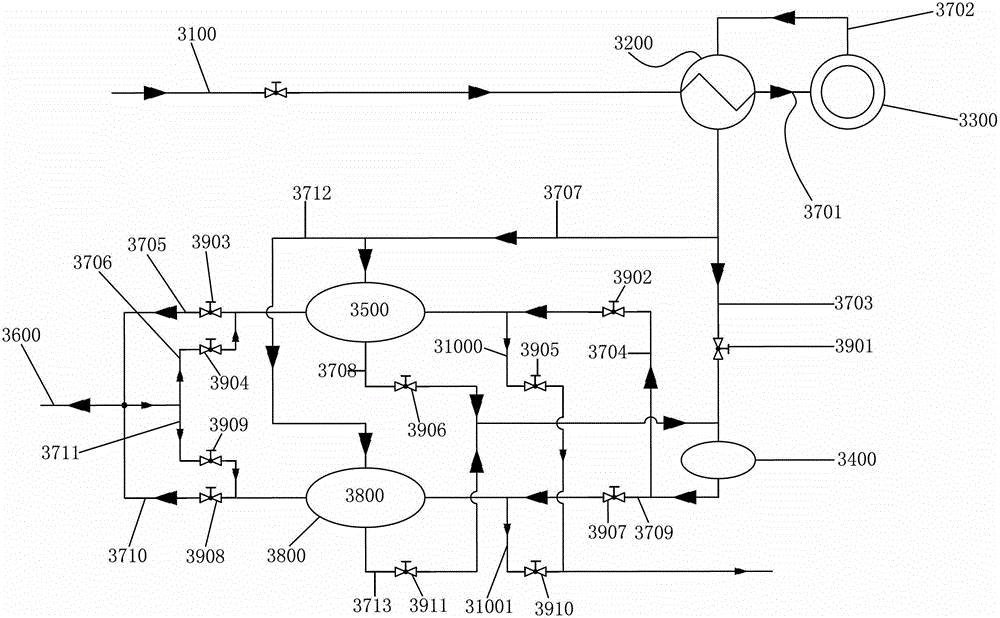

[0082] see image 3 and Figure 4Shown, repeat embodiment 1 or 2, and its difference is: described ammonia decomposition device 300 comprises ammonia gas input pipe 3100, heat exchanger 3200, ammonia decomposition furnace 3300, water cooler 3400, the 4th purifier 3500 and hydrogen Nitrogen mixture discharge pipe 3600; the heat exchanger 3200 is divided into a transverse channel and a longitudinal channel, and the transverse channel and the longitudinal channel are not connected to each other; the ammonia gas input pipe 3100 is connected to the inlet end of the transverse channel of the heat exchanger 3200 In communication, the outlet end of the transverse channel of the heat exchanger 3200 is connected to the inlet end of the ammonia decomposition furnace 3300 through the first branch pipe 3701, and the outlet end of the ammonia decomposition furnace 3300 is connected to the longitudinal direction of the heat exchanger 3200 through the second branch pipe 3702. The inlet end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com