Method for preparing Ti2AlC on basis of ultrasonic wave assistance thermal explosion reaction

A thermal explosion reaction and ultrasonic-assisted technology, which is applied in the preparation of relatively pure compounds by thermal explosion reaction, and in the field of preparation of Ti2AlC based on ultrasonic-assisted thermal explosion reaction, can solve the problems of poor controllability and difficulty, so as to improve the chemical reaction rate and accelerate material transfer speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Mix Ti powder (purity 99.9%, average particle size 20 μm), Al powder (purity 99.9%, average particle size 40 μm) and graphite powder (purity 99.9%, average particle size 40 μm) in a molar ratio of 2:1:1, Then fully grind in glass mortar for 30min to obtain mixed powder;

[0035] Step 2: put the mixed powder into a cylindrical steel mold with an inner diameter of 10mm, and cold-press it into a cylindrical green body with a thickness of 15mm under a radial pressure of 130MPa;

[0036] Step 3: In an argon atmosphere, the green body is heated at 730°C, and when heated for 100 s, ultrasonic waves with a power of 1.5 kW are directly added to the green body through an ultrasonic horn until the thermal explosion reaction ends, thereby obtaining The main phase is ternary Ti 2 The reaction product of AlC.

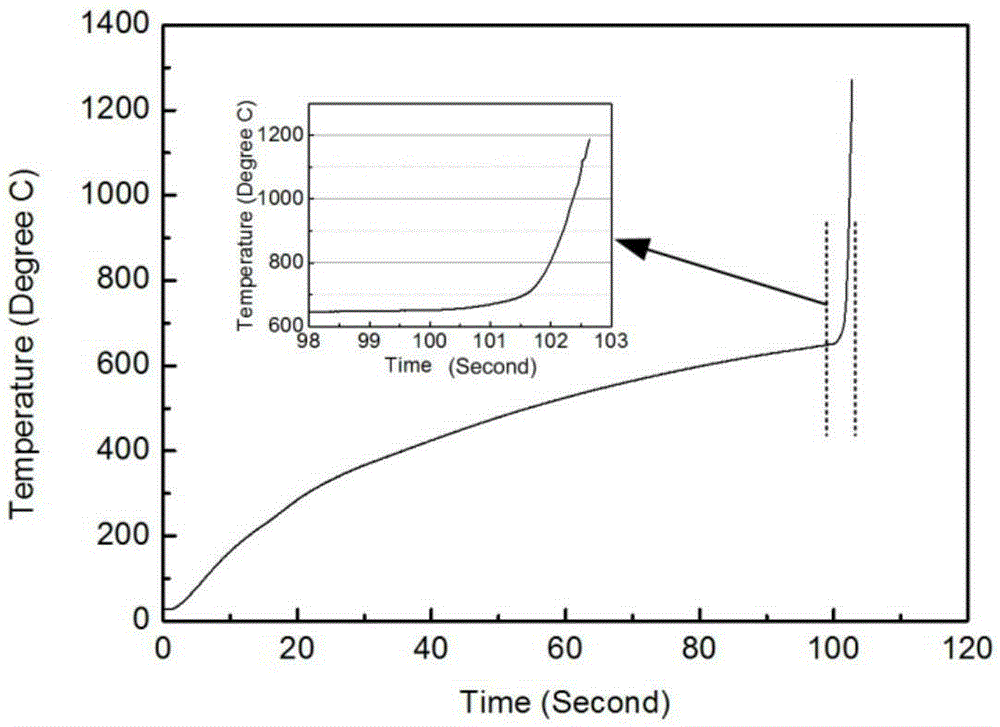

[0037] figure 1 It is the temperature change curve during the heating process of the Al-Ti-C body. When the green body is heated to 95s, its temperature is about 6...

Embodiment 2

[0040] Step 1: Mix Ti powder (purity 99.9%, average particle size 20 μm), Al powder (purity 99.9%, average particle size 40 μm) and graphite powder (purity 99.9%, average particle size 40 μm) in a molar ratio of 2:1:1, Then fully grind in glass mortar for 40min to obtain mixed powder;

[0041] Step 2: put the mixed powder into a cylindrical steel mold with an inner diameter of 10mm, and cold-press it into a cylindrical green body with a thickness of 10mm under a radial pressure of 130MPa;

[0042] Step 3: In an argon atmosphere, the green body is heated at 780 ° C, and when heated for 95 s, ultrasonic waves with a power of 1.0 kW are directly added to the green body through an ultrasonic horn until the thermal explosion reaction ends, thereby obtaining The main phase is ternary Ti 2 The reaction product of AlC.

Embodiment 3

[0044] Step 1: Mix Ti powder (purity 99.9%, average particle size 20 μm), Al powder (purity 99.9%, average particle size 40 μm) and graphite powder (purity 99.9%, average particle size 40 μm) in a molar ratio of 2:1:1, Then fully grind in glass mortar for 50min to obtain mixed powder;

[0045] Step 2: put the mixed powder into a cylindrical steel mold with an inner diameter of 10mm, and cold-press it into a cylindrical green body with a thickness of 20mm under a radial pressure of 130MPa;

[0046] Step 3: In an argon atmosphere, the green body is heated at 700 ° C, and when heated for 110 s, ultrasonic waves with a power of 1.3 kW are directly added to the green body through an ultrasonic horn until the thermal explosion reaction ends, thereby obtaining The main phase is ternary Ti 2 The reaction product of AlC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com