Low temperature solid phase preparation method of indium tin oxide nano particle powder

A nanoparticle, indium tin oxide technology, applied in tin oxide, chemical instruments and methods, nanotechnology, etc., can solve problems such as particle agglomeration, and achieve the effect of small particle size, low energy consumption, and increased dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

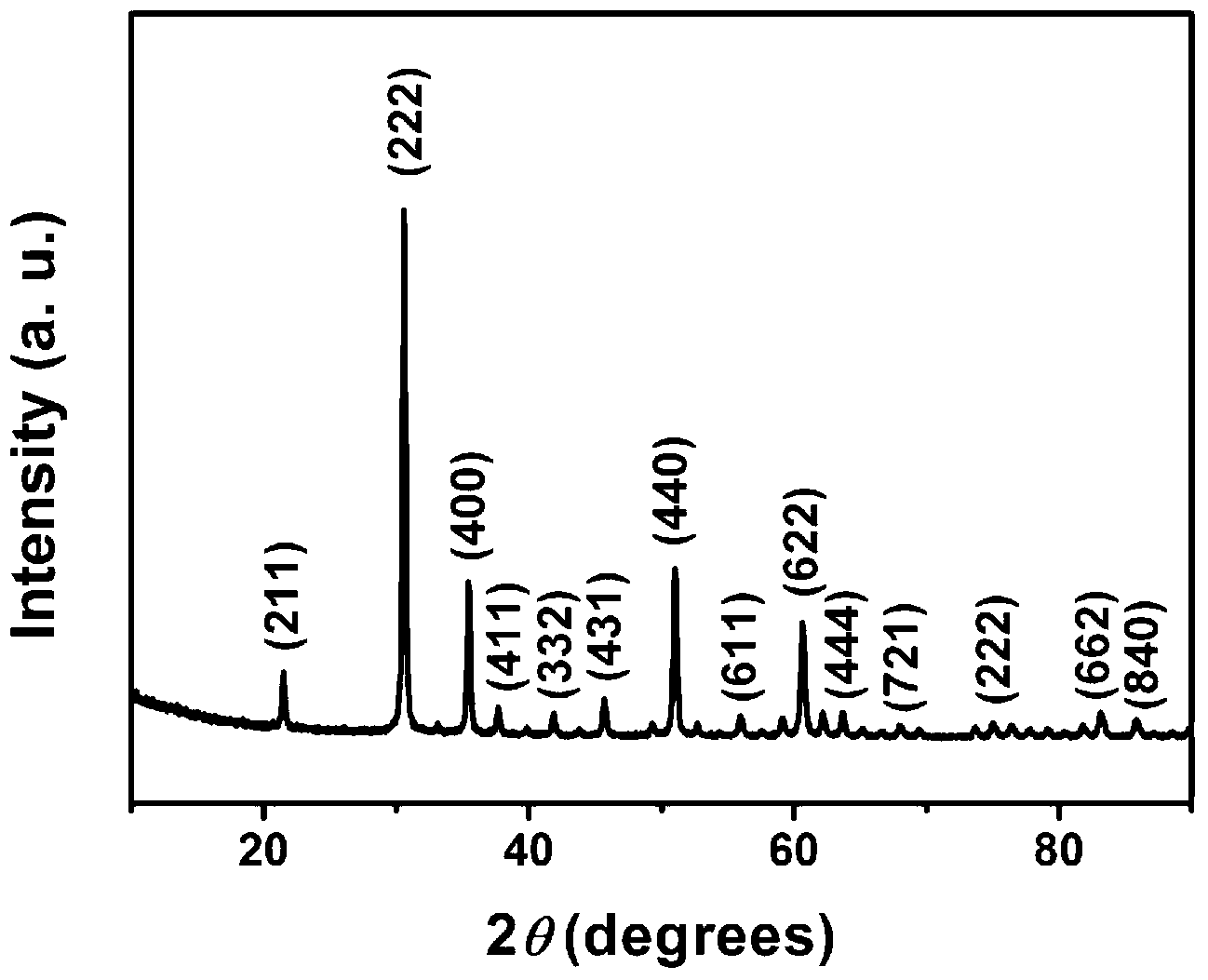

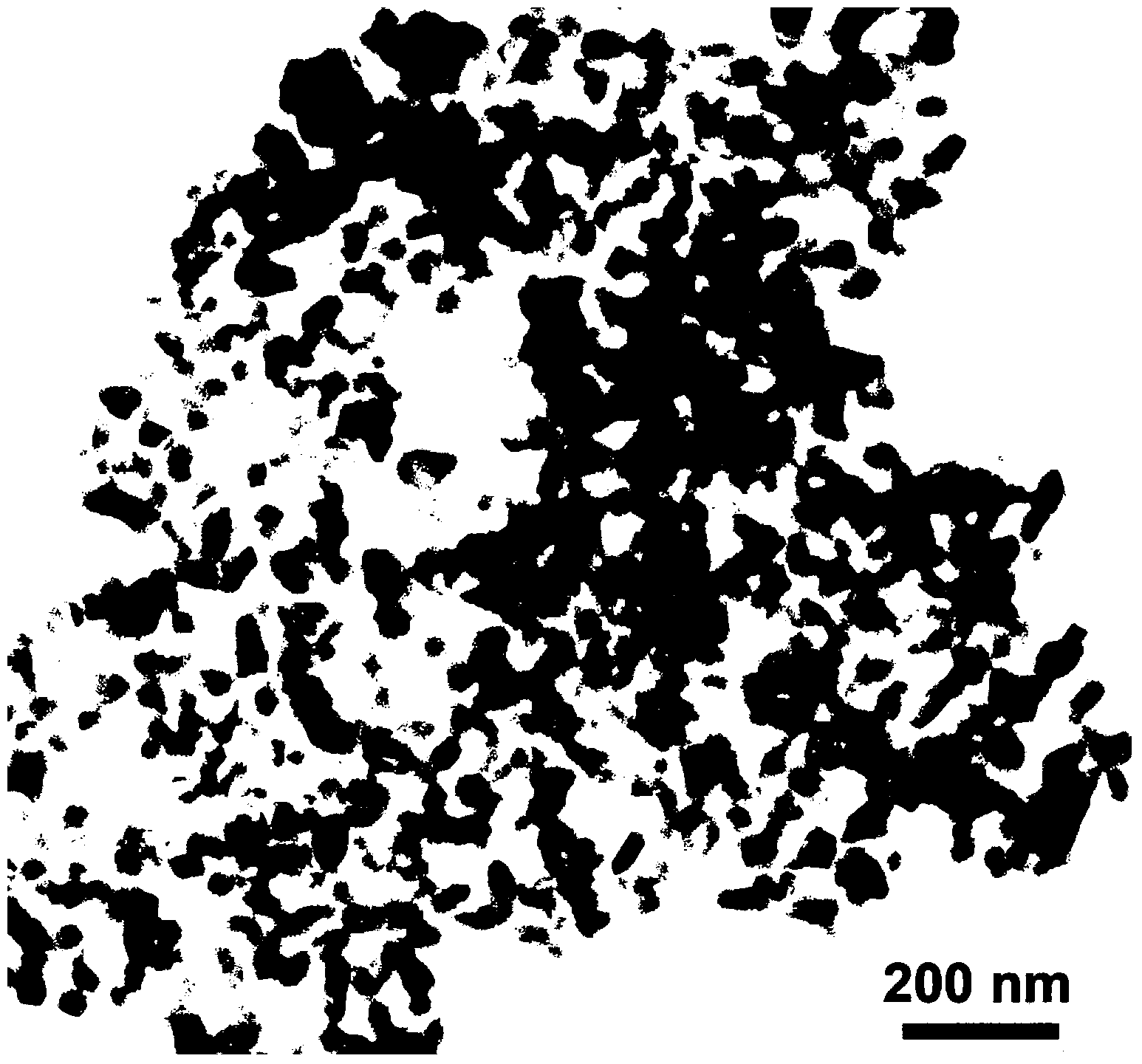

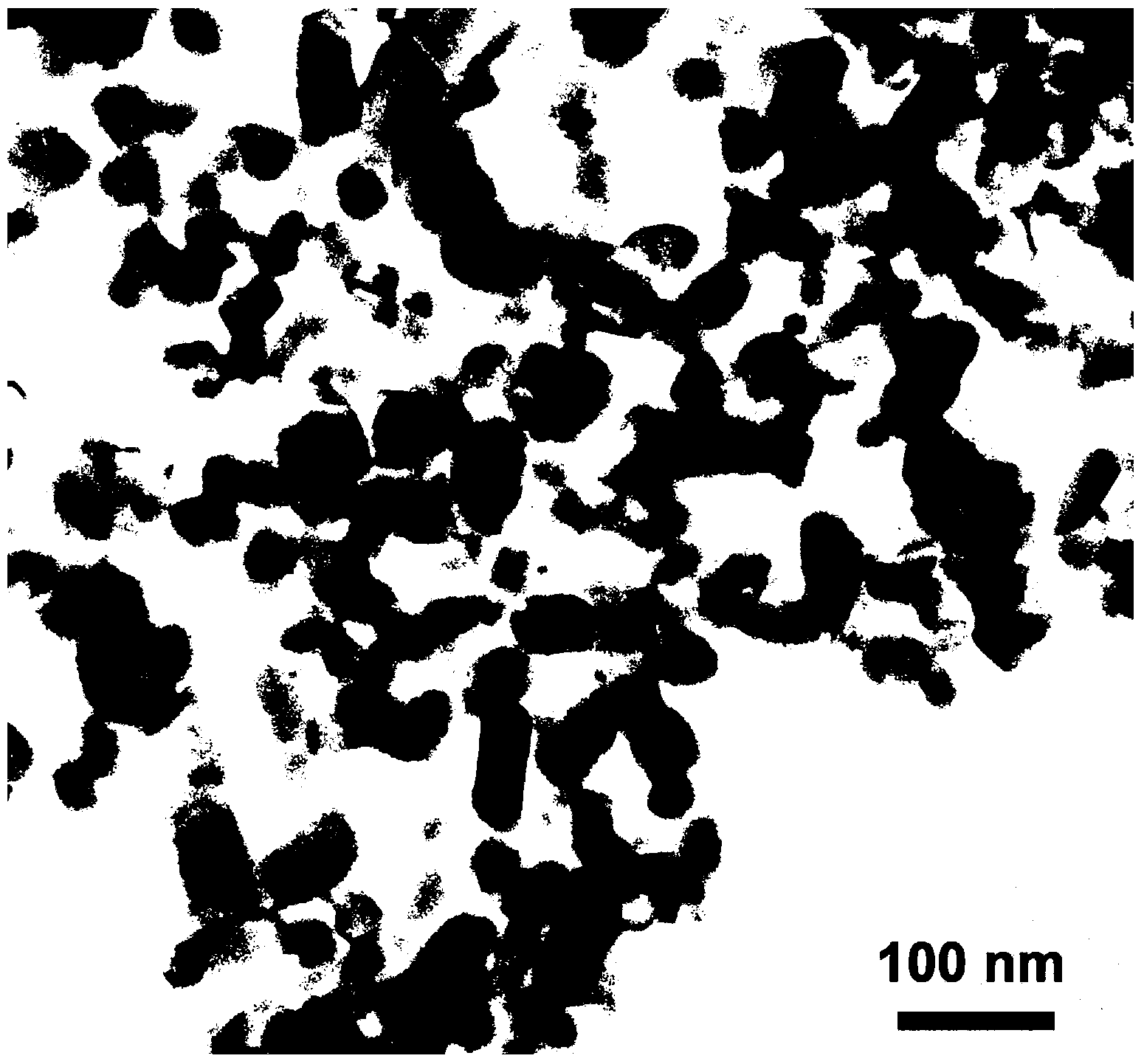

[0034] Indium metal with a purity greater than 99.99% is dissolved in nitric acid to prepare In3+ Concentration is 0.19mol / L solution, SnCl 4 ·5H 2 O was dissolved in distilled water to make a solution, and then the indium nitrate solution and the tin chloride solution were mixed according to In 2 o 3 :SnO 2 (wt%)=9:1 to make a mixed solution, then add NaCl to the mixed solution, where NaCl:In 3+ (mol%)=10:1, dissolve NaCl completely after stirring, then add ammonia water to the mixed solution, control the pH value of the reaction between 7.0 and 10.0, and finally generate the precursor of indium tin oxide, and then put the reaction system at 80 Drying treatment at ~90°C, and grinding to obtain mixed powder, then calcining the mixed powder at 400°C for 2 hours, washing the calcined product with water to remove NaCl, drying at 80-90°C, and finally Indium tin oxide nano particle powder is obtained. figure 1 is the X-ray diffraction spectrum of the prepared indium tin oxide ...

Embodiment 2

[0036] Indium metal with a purity greater than 99.99% is dissolved in nitric acid to prepare In 3+ Concentration is 0.19mol / L solution, SnCl 4 ·5H 2 O was dissolved in distilled water to make a solution, and then the indium nitrate solution and the tin chloride solution were mixed according to In 2 o 3 :SnO 2 (wt%)=9:1 to prepare a mixed solution, and then add Na to the mixed solution 2 SO 4 , where Na 2 SO 4 :In 3+ (mol%)=20:1, after stirring Na 2 SO 4 Dissolve completely, then add ammonia water to the mixed solution, control the pH value of the reaction between 7.0 and 10.0, and finally generate an indium tin oxide precursor, then dry the reaction system at 80-90°C, and grind it Finally, the mixed powder is obtained, and then the mixed powder is calcined at 400°C for 2 hours, and the calcined product is washed with water to remove Na 2 SO 4 Finally, dry treatment is carried out under the condition of 80-90° C. to finally obtain indium tin oxide nano particle powd...

Embodiment 3

[0038] This embodiment proceeds according to the following steps:

[0039] 1) Dissolve metal indium with a purity greater than 99.99% in concentrated sulfuric acid to form an initial solution, and the In of the configured initial solution 3+ The concentration is 0.01mol / L.

[0040] 2) Add tin metal salt to the initial solution to form a mixed solution A; the tin metal salt can be Sn(SO 4 ) 2 .

[0041] 3) Then add a water-soluble inorganic salt to the mixed solution A, the water-soluble inorganic salt and In 3+ The molar ratio is 5. In this embodiment, KCl is selected as the water-soluble inorganic salt; after stirring, the inorganic salt is completely dissolved to obtain a mixed solution B.

[0042] 4) Add ammonia water to the mixed solution B, control the pH value of the reaction between 7.0 and 10.0, and finally generate an indium tin oxide precursor;

[0043] 5) Dry the reaction system in step 4) at 80°C, and grind to obtain a mixed powder;

[0044] 6) Put the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com