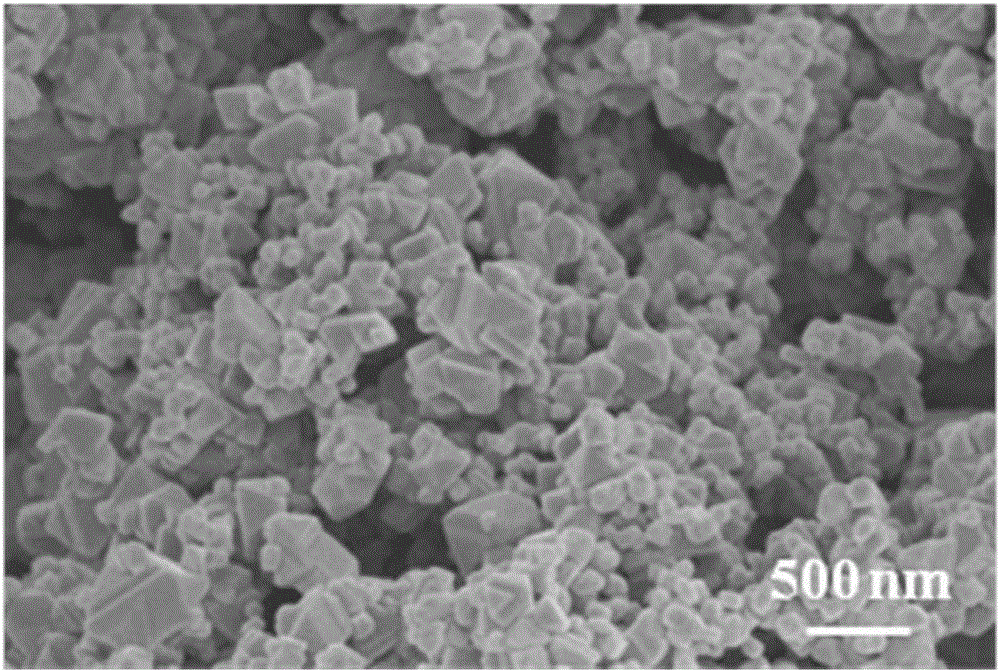

Rod-like cobalt ferrite powder and preparation method thereof

A technology of cobalt ferrite powder and cobalt ferrite, which is applied in the field of material science, can solve the problems of small specific surface area and poor dispersion of cobalt ferrite particles, and achieve the effect of increasing specific surface area, uniform shape and improving photocatalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A rod-shaped CoFe 2 o 4 and preparation method thereof, comprising the following steps:

[0035] Step 1: CoFe 2 o 4 According to the molar ratio, respectively weigh the Co(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, with 1 mmol of CoFe 2 o 4 In total, add 40-80mL of water and 2mmol of citric acid, mix and stir magnetically to fully dissolve to obtain a reddish-brown mixed solution A; the role of citric acid is a complexing agent to slowly release metal ions, It also acts as a dispersant.

[0036] Step 2: Slowly add ammonia solution dropwise to the reddish-brown mixed solution A, adjust the pH value of the mixed solution A between 6.5 and 7.5, and continue stirring for 4 to 8 hours after obtaining the dark red suspension B;

[0037] Step 3: Transfer the suspension B to a larger beaker, place it in an oven at 160-200°C, and perform a sol-gel reaction for 2-3 hours to dehydrate it and remove organic matter;

[0038] Step 4: After the oven is cooled to room temperatu...

Embodiment 1

[0046] A rod-shaped CoFe 2 o 4 and preparation method thereof, comprising the following steps:

[0047] (1) According to CoFe 2 o 4 In the molar ratio, respectively weigh the Co(NO 3 ) 2 ·6H 2 O, 2mmol of Fe(NO 3 ) 3 9H 2 O, 40mL of water and 2mmol of citric acid were mixed and then magnetically stirred to fully dissolve to obtain mixed solution A;

[0048] (2) Slowly add ammonia solution dropwise to the mixed solution A, adjust the pH value of the mixed solution A to 6.5, and after obtaining the dark red suspension B, continue stirring for 4 h;

[0049] (3) Pour the suspension B into a larger beaker and place it in an oven at 160°C for 2 hours to dehydrate and remove organic matter;

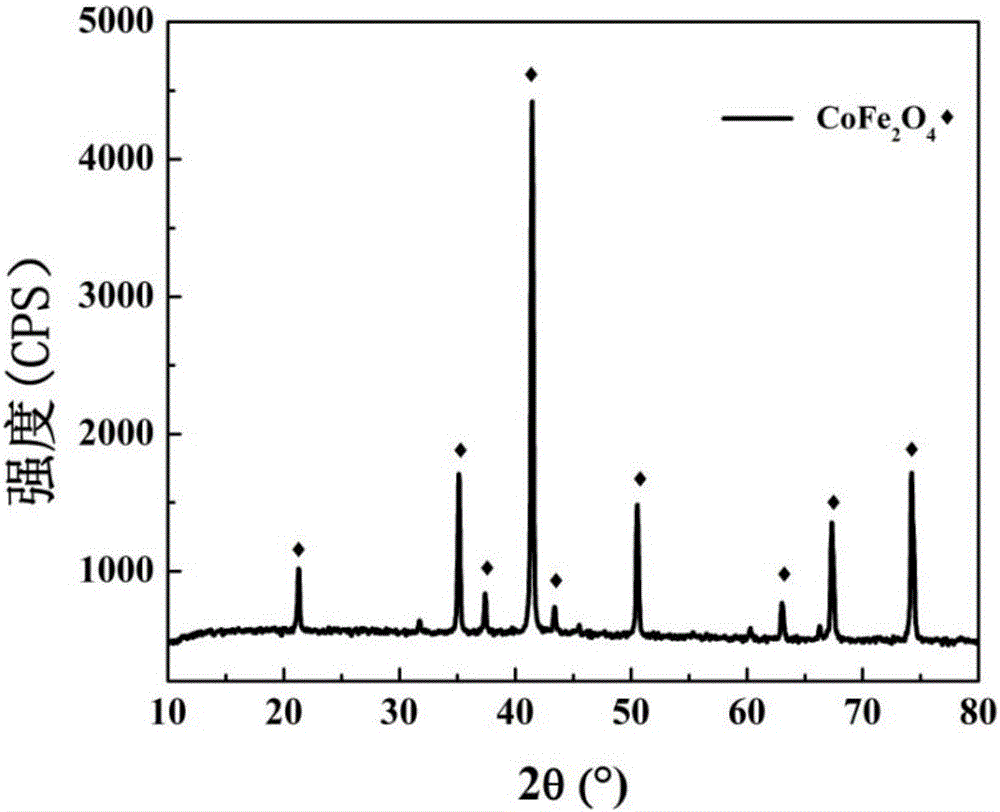

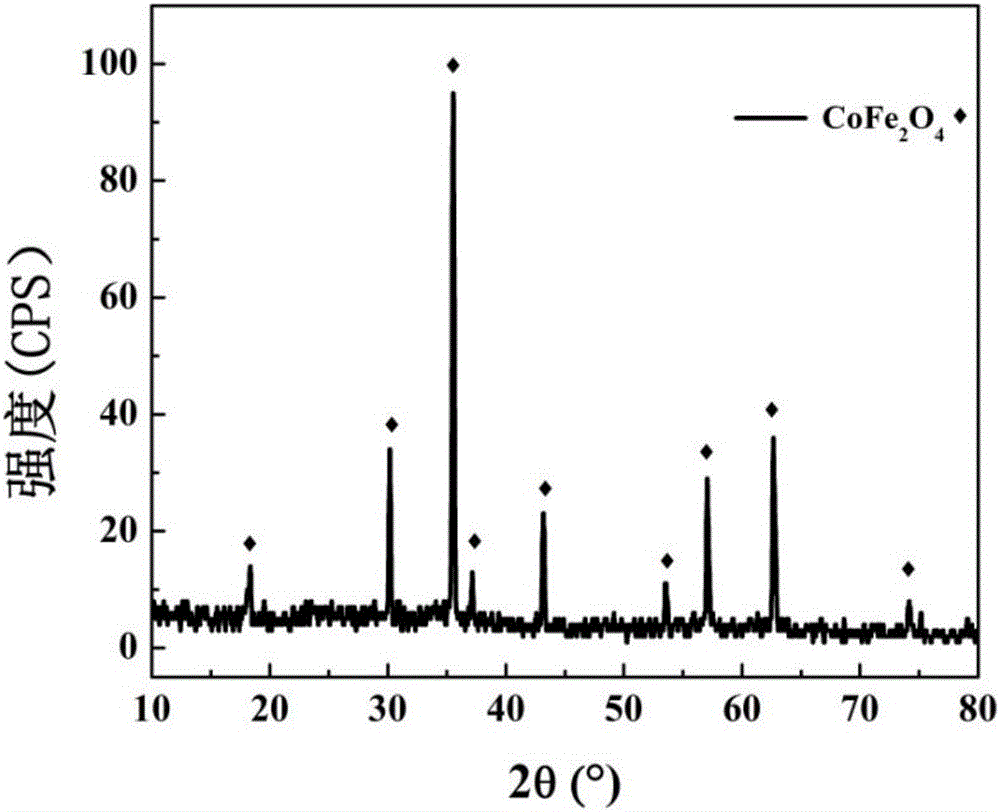

[0050] (4) After the oven is cooled to room temperature, put the powder obtained after drying into a high-temperature furnace and burn at 900° C. for 1 hour to obtain cobalt ferrite powder.

[0051] (5) Mix 1 mg of the cobalt ferrite powder obtained in (4) and 500 mL of N,N-dimethylfo...

Embodiment 2

[0057] A rod-shaped CoFe 2 o 4 and preparation method thereof, comprising the following steps:

[0058] (1) According to CoFe 2 o 4 In the molar ratio, respectively weigh the Co(NO 3 ) 2 ·6H 2 O, 2mmol of Fe(NO 3 ) 3 9H 2 O, 50mL of water and 2mmol of citric acid, magnetically stirred after mixing, fully dissolved to obtain mixed solution A;

[0059] (2) Slowly add ammonia solution dropwise to the mixed solution A, adjust the pH value of the mixed solution A to 7, and after obtaining the dark red suspension B, continue stirring for 5.5 hours;

[0060] (3) Pour the suspension B into a larger beaker and place it in an oven at 170°C for 140 minutes to dehydrate and remove organic matter;

[0061] (4) After the oven is cooled to room temperature, put the powder obtained after drying into a high-temperature furnace and burn at 1000° C. for 2 hours to obtain cobalt ferrite powder.

[0062] (5) Mix 1 mg of the cobalt ferrite powder obtained in (4) and 600 mL of N,N-dimethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com