Preparation method and application of precious metal loaded type cobalt oxide nano catalyst

A nano-catalyst, cobalt tetroxide technology, applied in metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, cobalt oxide/cobalt hydroxide, etc., can solve the problem that the temperature cannot meet the exhaust gas of lean-burn engine. , the lack of precious metal and carrier interaction, the catalyst does not have good stability and other problems, to achieve good industrial application prospects, good high temperature structural stability, low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

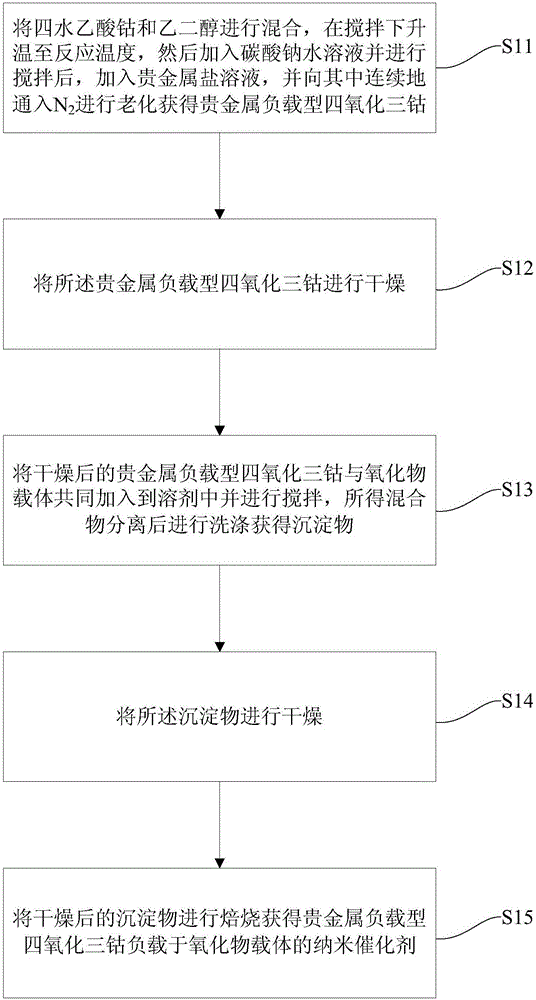

[0044] Such as figure 1 Shown, the present invention provides a kind of preparation method of noble metal-loaded cobalt tetroxide nano-catalyst, comprises steps:

[0045] Such as figure 1 Shown, at first carry out step 1) S11, cobalt acetate tetrahydrate and ethylene glycol are mixed, and described ethylene glycol is used as surfactant and reducing agent in synthesis, is warming up to reaction temperature under stirring, then adds sodium carbonate After the aqueous solution is stirred, a noble metal salt solution is added, and N2 is continuously fed into it for aging to obtain noble metal-supported tricobalt tetroxide.

[0046] As an example, in step 1), the molar ratios of cobalt acetate tetrahydrate, ethylene glycol and sodium carbonate are 8-12 mmol: 25-35 mmol: 16-24 mmol.

[0047] As an example, in step 1), the reaction temperature is 60-100°C. Preferably, the reaction temperature is 80°C.

[0048] As an example, the noble metal salt includes one of noble metal nitrat...

Embodiment 1

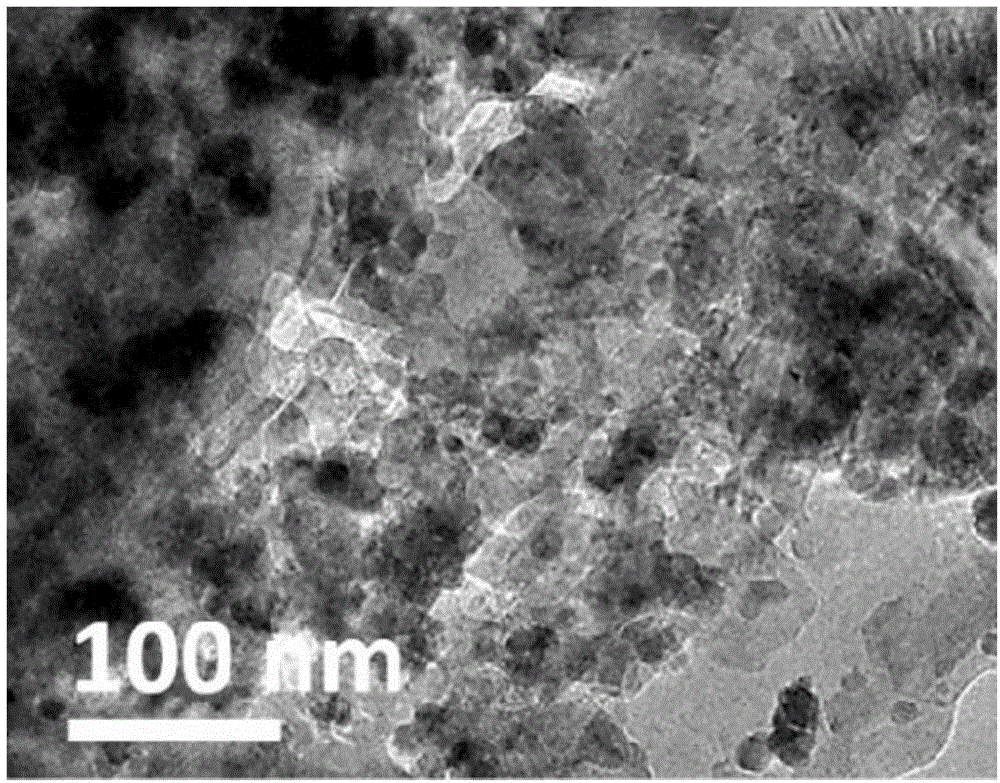

[0070] Weigh 10mmol cobalt acetate tetrahydrate (Co(CH 3 COO) 2 4H 2 O) Dissolve in 30ml ethylene glycol, gradually heat to 80°C, then add 0.2mol / L Na dissolved in 100ml deionized water 2 CO 3 aqueous solution. After stirring vigorously for 10min, add 20ml of 0.1610g Pd(NO 3 ) 2 solution, and continuously feed N into it 2 . After reacting for one hour, it was cooled to room temperature, centrifuged and washed with deionized water, and then vacuum-dried at 60° C. for 12 hours. The resulting product Pd / Co 3 o 4 powder (50mg) with Al 2 o 3 The powder (450mg) was added together into 15mL ethanol and stirred for 12h, centrifuged with ethanol, washed clean, and dried in vacuum at 120°C for 12h. Then bake at 500°C for 5h. Finally, the calcined body is ground into fine powder, extruded in a mold under a pressure of 40kN, crushed and sieved to obtain catalyst particles with a particle size of 40-60 mesh. The catalytic reaction conditions are: the temperature of the cataly...

Embodiment 2

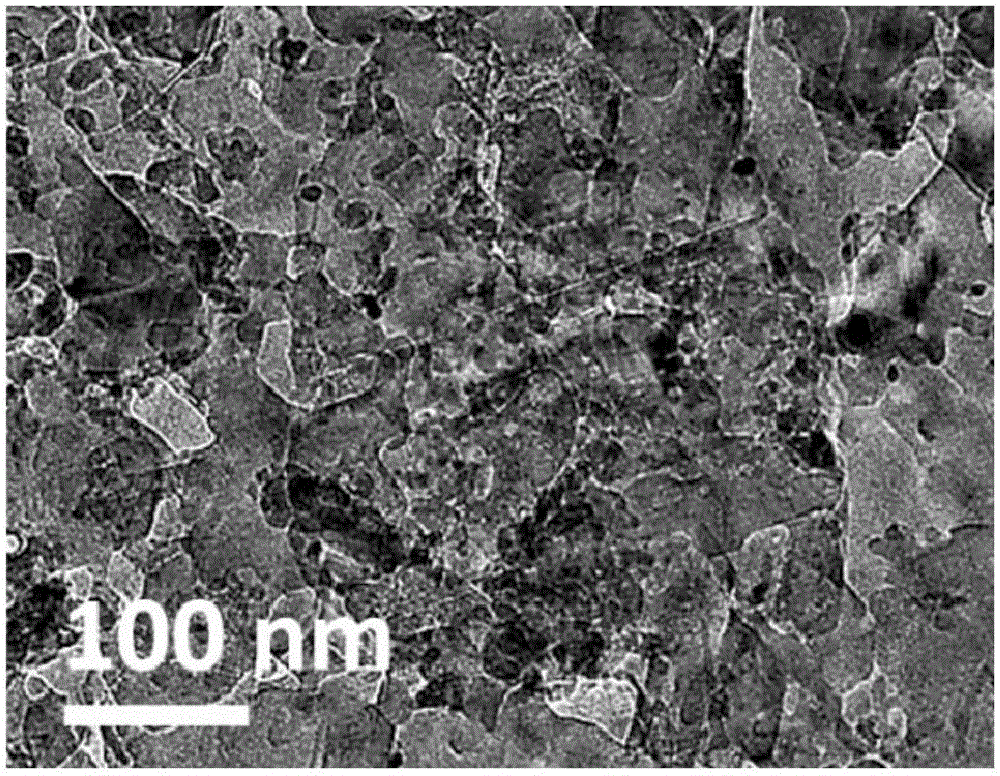

[0073] Weigh 5mmol cobalt acetate tetrahydrate (Co(CH 3 COO) 2 4H 2 O) Dissolve in 15ml of ethylene glycol, gradually heat to 80°C, then add 0.2mol / L Na dissolved in 100ml of deionized water 2 CO 3 aqueous solution. After vigorous stirring for 10 min, 20 ml of 0.0525 g Pd(NO 3 ) 2 solution, and continuously feed N into it 2 . After reacting for one hour, it was cooled to room temperature, centrifuged and washed with deionized water, and then vacuum-dried at 60° C. for 12 hours. The resulting product Pd / Co 3 o 4 powder (50mg) with Al 2 o 3 The powder (450mg) was added together into 15mL ethanol and stirred for 12h, centrifuged with ethanol, washed clean, and dried in vacuum at 120°C for 12h. Then bake at 500°C for 5h. Finally, the calcined body is ground into fine powder, extruded in a mold under a pressure of 40kN, crushed and sieved to obtain catalyst particles with a particle size of 40-60 mesh. The catalytic reaction conditions are: the temperature of the cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com