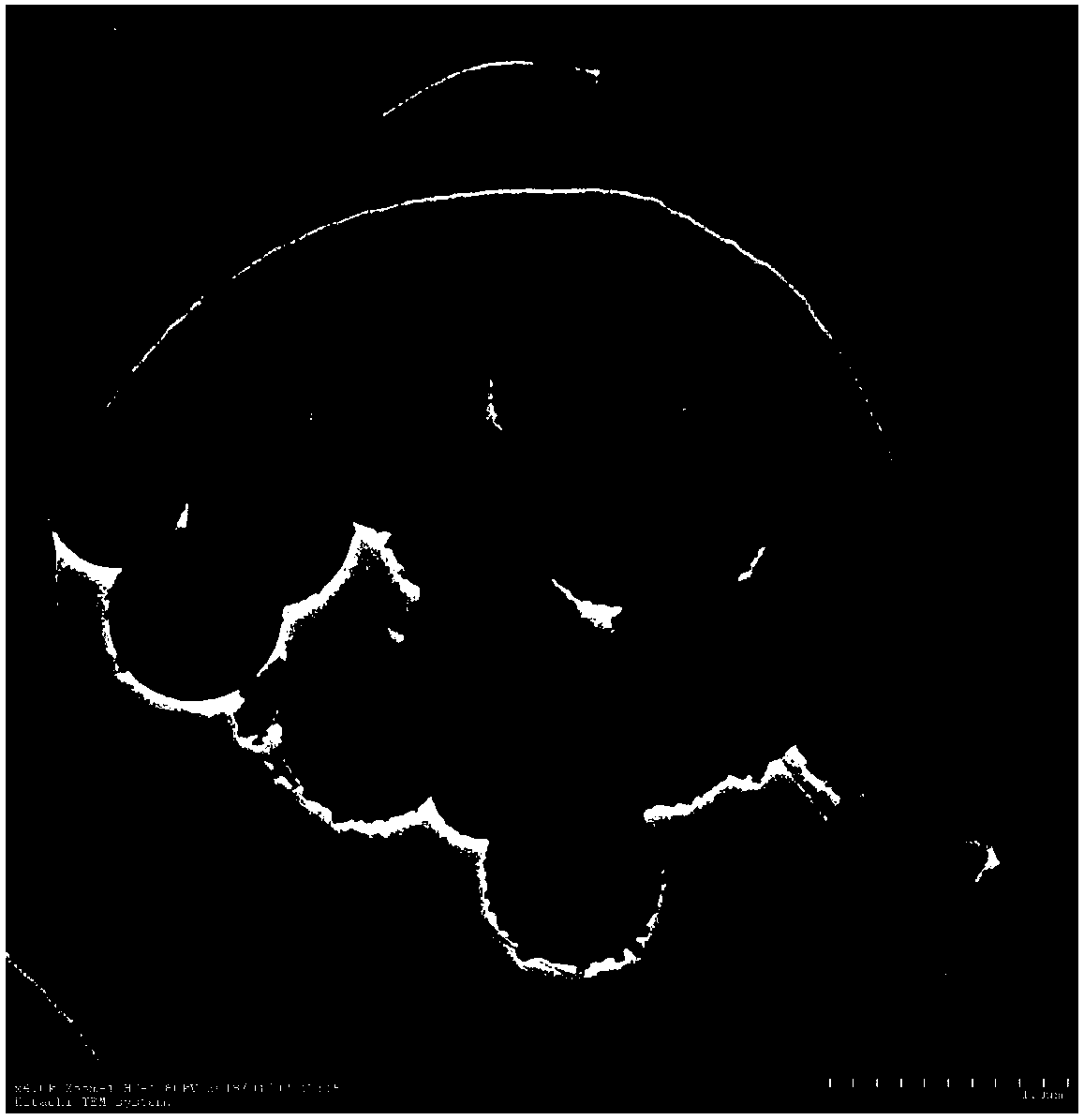

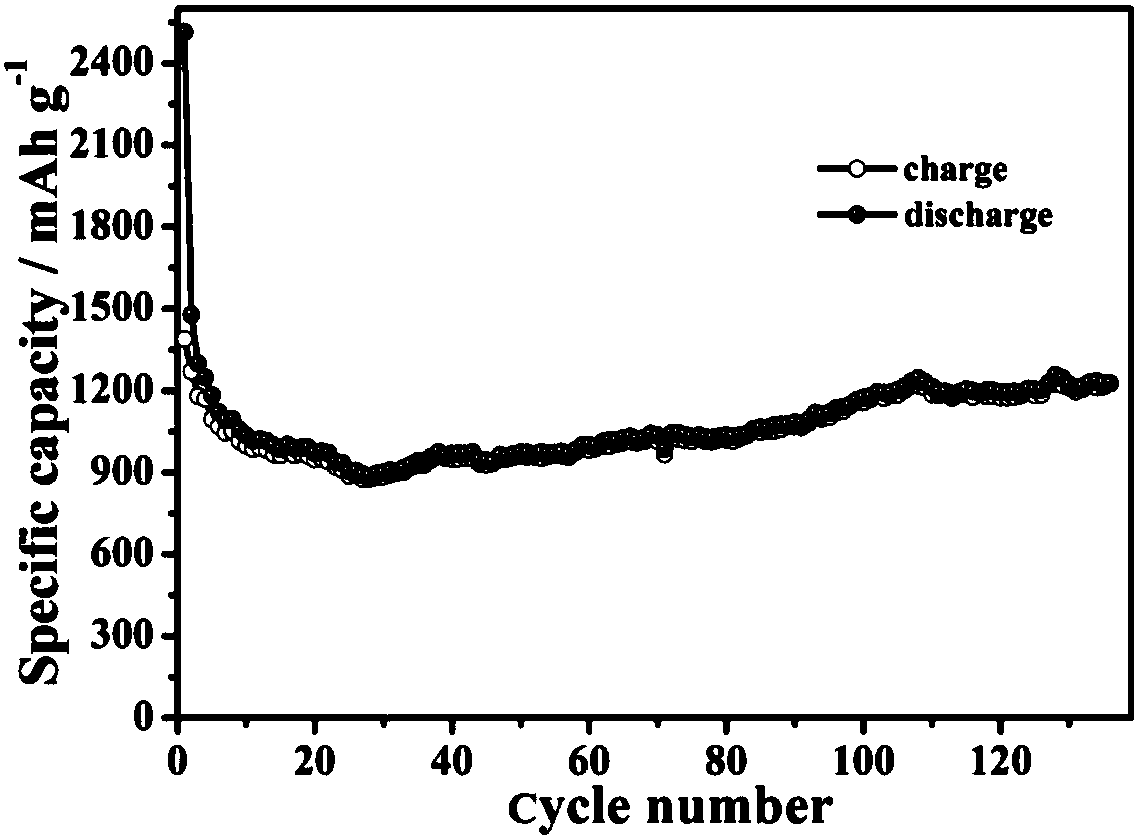

Preparation method of high-performance carbon-silicon composite hollow nano-sphere negative material

A silicon-carbon composite and anode material technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex process, high cost, unfavorable industrial production, etc., and achieve simple process and easy operation Convenient and beneficial to industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Dissolve 1 g of phenol in a mixed solvent of water and methanol at a certain volume ratio, stir magnetically for 30 minutes to form a clear solution, add 2.5 mL of ethylenediamine, and continue stirring for 30 minutes.

[0023] (2) in the solution of step (1), add 4g tetradecyltrimethyl ammonium chloride, after stirring for a certain hour to make it fully dissolve, add the acetaldehyde of 1.8mL and the methyl orthosilicate of 15mL in order, Stir for 10 hours.

[0024] (3) Transfer the solution obtained in step (2) to a three-necked flask, and use a microwave heater to treat it at 80°C for 40 minutes. After the reaction is completed, cool to room temperature, centrifuge, wash and dry to obtain a composite of phenolic resin and silicon oxide .

[0025] (4) Put the composite obtained in step (3) into a high-temperature tube furnace, heat-treat at 500° C. for 5 hours under a nitrogen atmosphere, and naturally cool to room temperature to obtain a composite product of si...

Embodiment 2

[0029] (1) Dissolve 3g of p-aminophenol in a mixed solvent of water and isopropanol at a certain volume ratio, and stir magnetically for 30 minutes to form a clear solution, then add 5mL of ammonia water and continue stirring for 30 minutes.

[0030] (2) Add 8g tetradecyltrimethylammonium bromide to the solution of step (1), after stirring for a certain period of time to make it fully dissolve, add 6mL of propionaldehyde and 20mL of propyl orthosilicate in order, stir 24 hours.

[0031] (3) Transfer the solution obtained in step (2) to a three-necked flask, and use a microwave heater to treat it at 120°C for 30 minutes. After the reaction is completed, cool to room temperature, centrifuge, wash and dry to obtain a composite of phenolic resin and silicon oxide .

[0032] (4) Put the composite obtained in step (3) into a high-temperature tube furnace, heat-treat at 700° C. for 10 hours under a nitrogen atmosphere, and naturally cool to room temperature to obtain a composite pro...

Embodiment 3

[0035] (1) Dissolve 3.5g of catechol in a mixed solvent of water and methanol at a certain volume ratio, and magnetically stir for 30 minutes to form a clear solution, then add 6.5mL of ethylenediamine and continue stirring for 30 minutes.

[0036] (2) Add 5g tetradecyl trimethyl ammonium chloride in the solution of step (1), after stirring for a certain period of time to make it fully dissolve, add the formaldehyde of 7mL and the methyl orthosilicate of 30mL in order, stir 24 Hour.

[0037] (3) Transfer the solution obtained in step (2) to a three-necked flask, and use a microwave heater to treat it at 100°C for 25 minutes. After the reaction is completed, cool to room temperature, centrifuge, wash and dry to obtain a composite of phenolic resin and silicon oxide .

[0038] (4) Put the composite obtained in step (3) into a high-temperature tube furnace, heat-treat at 800° C. for 12 hours under a nitrogen atmosphere, and cool naturally to room temperature to obtain a composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com