Preparation method of CsPb2Br5 inorganic perovskite nanosheet

A technology of nanosheets and inorganic calcium, which is applied in the direction of inorganic chemistry, chemical instruments and methods, lead compounds, etc., can solve the problems of limiting the continued growth of two-dimensional sheets, the inability to achieve large areas, and high reaction temperatures, and achieve industrial production and crystallization The effect of good performance and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

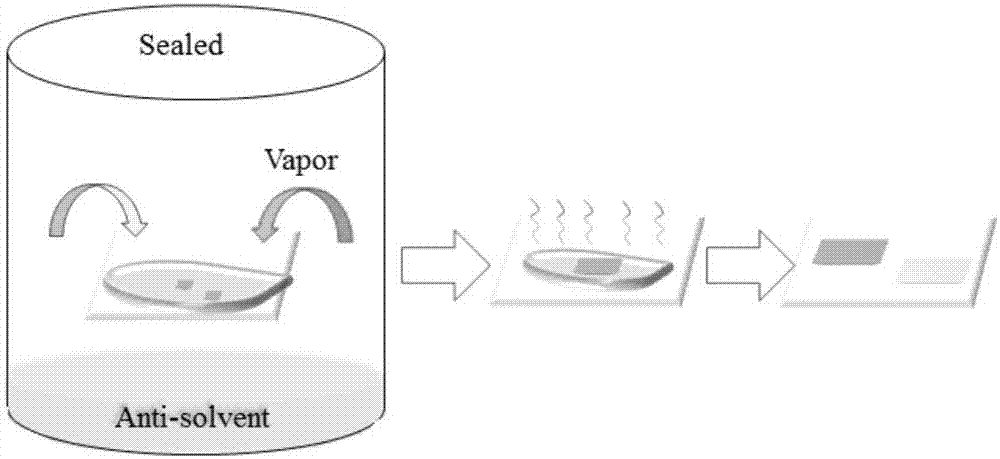

[0025] A CsPb 2 Br 5 A method for preparing an inorganic perovskite nanosheet, comprising the following steps:

[0026] Step 1, equimolar cesium bromide (CsBr) and lead bromide (PbBr 2 ) into 5 mL of dimethyl sulfoxide, and stirred to react to obtain a mixed solution with a concentration of 20 to 70 mmol / L; then add 10 to 20 μL of n-octanoic acid to the mixed solution to obtain a precursor solution;

[0027] Step 2, methanol and ethanol are mixed according to the volume ratio of (0.6-1.5): 1, to obtain 8-10L anti-solvent solution;

[0028] Step 3, the silicon dioxide substrate is ultrasonically cleaned in acetone and ethanol in sequence, and then cleaned by ozone plasma;

[0029] Step 4. Place the substrate cleaned in step 3 on the stage, and then put the substrate and the stage together into a glass jar; take 10-30 μL of the precursor solution prepared in step 1 and add it dropwise to the cleaned on a silicon dioxide substrate;

[0030] Step 5. After adding 8-10L of the ...

Embodiment 1

[0035] A CsPb 2 Br 5 A method for preparing an inorganic perovskite nanosheet, comprising the following steps:

[0036] Step 1, the CsBr and PbBr of 0.25mmol 2 Dissolve in 5mL dimethyl sulfoxide solvent, stir and react, and prepare a mixed solution with a concentration of 50mmol / L; then add 10 μL n-octanoic acid to the mixed solution, and mix well to obtain a precursor solution;

[0037] Step 2, methanol and ethanol are mixed according to the volume ratio of 1:1 to obtain 10L of anti-solvent solution;

[0038] Step 3, ultrasonically clean the silicon dioxide substrate in acetone and ethanol for 15 minutes, and then clean it with ozone plasma for 5 minutes;

[0039] Step 4. Place the substrate cleaned in step 3 on the stage, and then put the substrate and the stage together into a glass jar; take 20 μL of the precursor solution prepared in step 1 and add it dropwise to the cleaned substrate in step 3 on a silicon dioxide substrate;

[0040] Step 5. Add 10L of the anti-solv...

Embodiment 2

[0042] The difference between this embodiment and embodiment 1 is that the standing time in step 5 is 24h, and the rest of the operations are the same as in embodiment 1.

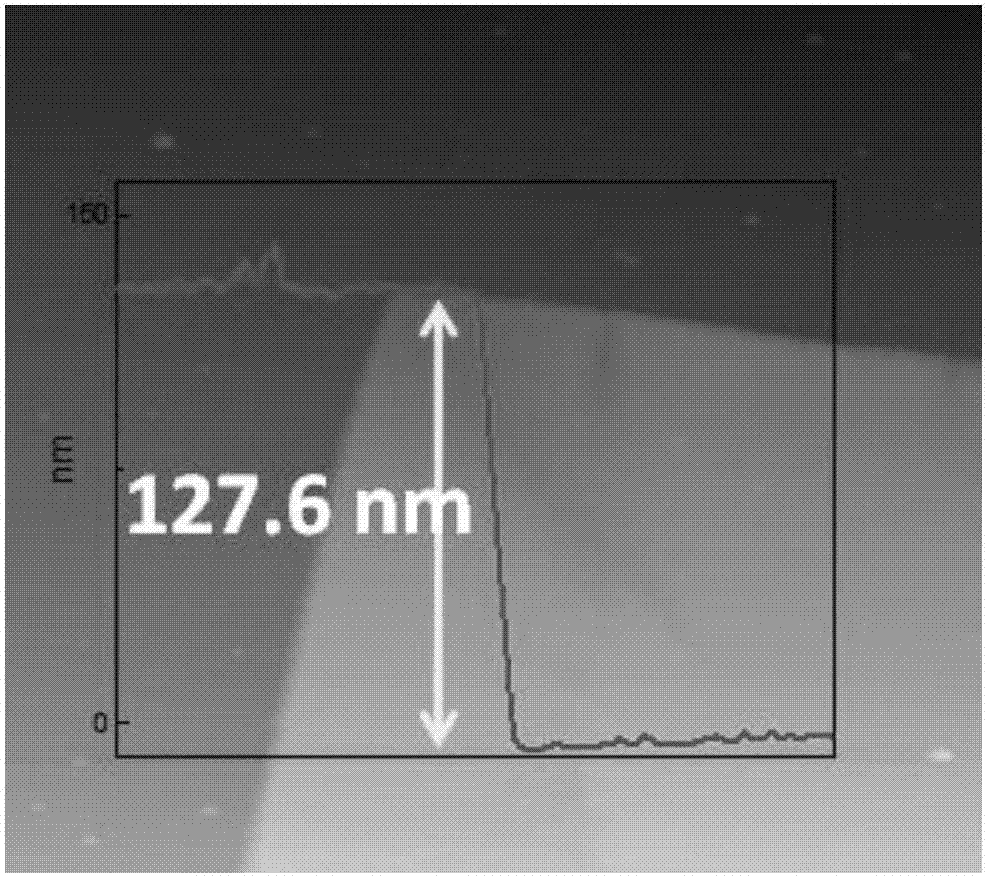

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com