Hollow carbon sphere and preparation method thereof

A technology for hollow spheres and silica spheres, which is applied to the field of carbon hollow spheres and their preparation, can solve the problems of poor control of product structure and morphology, complicated processes, and difficulty in industrialized production, and achieves easy industrialized production and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

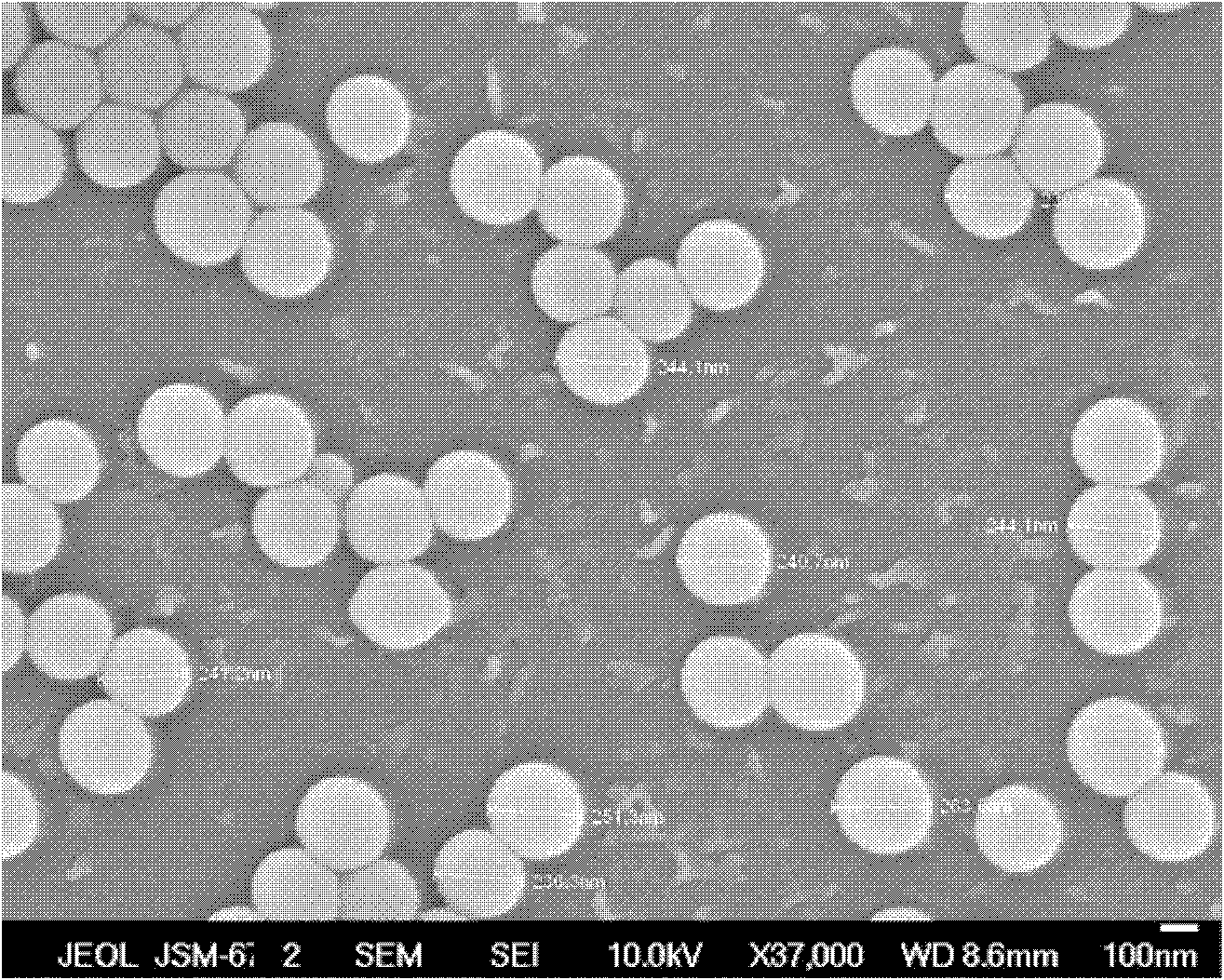

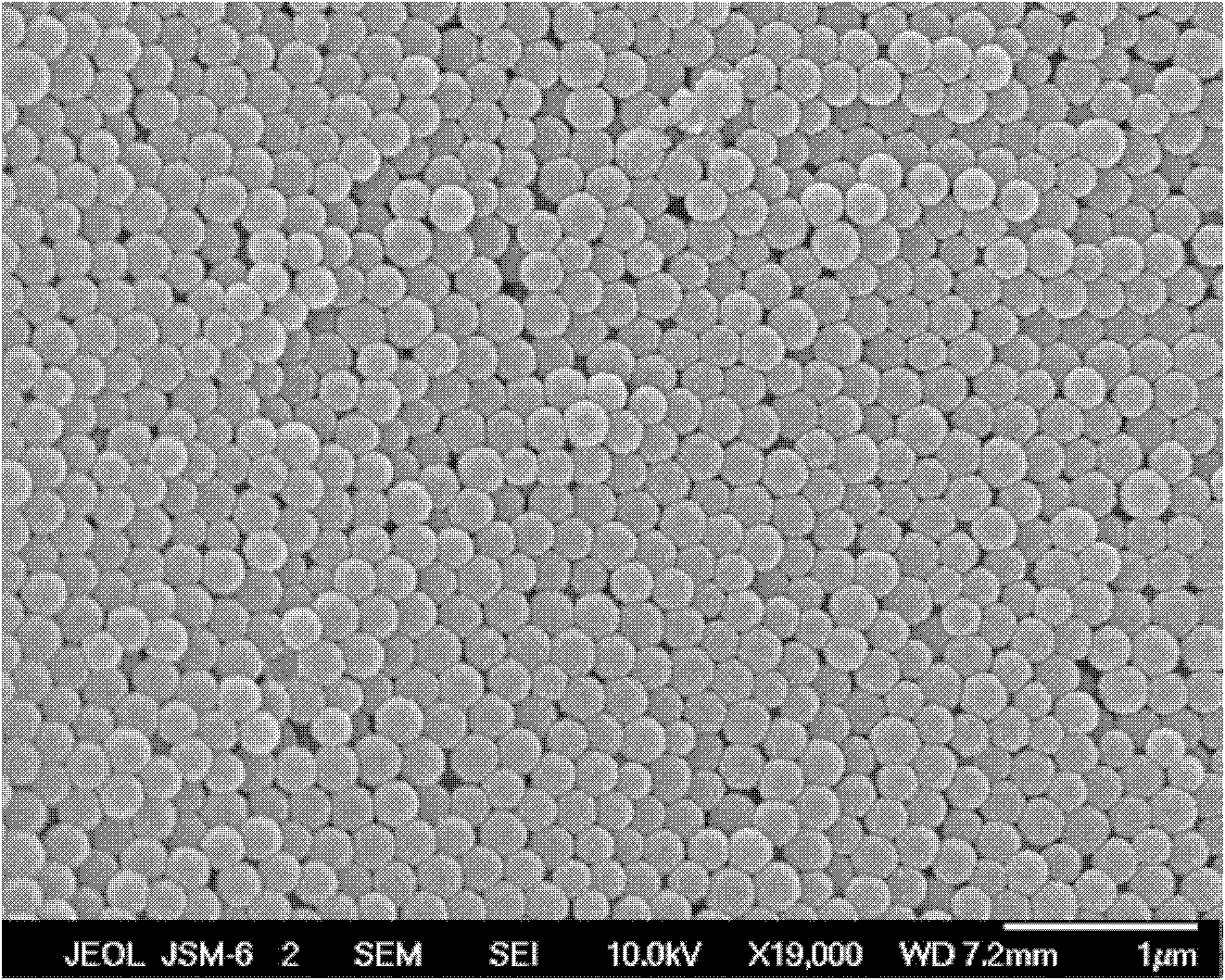

[0029] Embodiment 1, the preparation of carbon hollow sphere

[0030] (1) Preparation of silica spheres

[0031] Prepare an ethanol solution of ethyl orthosilicate at 25°C (the ratio of ethyl orthosilicate to ethanol is 1:4 by volume) and 30 mL of ethanol solution of ammonia (the ratio of ammonia to ethanol is 1:4) 60mL (in this system, the volume ratio of ethyl orthosilicate, ammonia water and ethanol is 1:2:12), under vigorous stirring (stirring speed 1000r / min), 2mL of the above prepared ethyl orthosilicate The ethanol solution was added to the ethanol solution of the ammonia water prepared above, and vigorously stirred (stirring speed 1000r / min) for 10 minutes, and then the remaining tetraethyl orthosilicate prepared above was mixed at a lower speed (stirring speed 800r / min) Add the ethanol solution to the ethanol solution of ammonia water prepared above, and keep stirring (stirring rate 800r / min) for 4h. After the reaction, the powder was collected by centrifuging, wash...

Embodiment 2

[0038] Embodiment 2, the preparation of carbon hollow sphere

[0039] (1) Preparation of silica spheres

[0040] Prepare a propanol solution of tetraethyl orthosilicate at 30°C (the volume fraction ratio of tetraethyl orthosilicate and propanol is 1:5) and 30 mL of a propanol solution of ammonia water (the volume fraction ratio of ammonia water and propanol is 1:4) 90mL (in this system, the volume ratio of tetraethyl orthosilicate, ammonia water and propanol is 1:3.6:19.4), under vigorous stirring (stirring rate 1000r / min), 5mL of the above-mentioned The propanol solution of ethyl silicate was added in the propanol solution of ammonia water prepared above, and vigorously stirred (stirring speed 1500r / min) for 20 minutes, then the above-mentioned prepared Add the remaining propanol solution of ethyl tetrasilicate to the above prepared ammonia solution in propanol, and keep stirring (stirring rate 600r / min) for 6h. Afterwards, the powder was collected by centrifuging, washing ...

Embodiment 3

[0052] Embodiment 3, the preparation of carbon hollow sphere

[0053] (1) Preparation of silica spheres

[0054] Prepare n-butanol solution of tetraethyl orthosilicate at 30°C (the volume fraction ratio of tetraethyl orthosilicate and n-butanol is 1:1) and 40 mL of n-butanol solution of ammonia water (volume of ammonia water and n-butanol Parts ratio is 1:2) 60mL (in this system, the volume and parts ratio of tetraethyl orthosilicate, ammonia water and n-butanol is 1:1:3), under vigorous stirring (stirring rate 1000r / min) 1mL The n-butanol solution of the tetraethyl orthosilicate prepared above was added in the n-butanol solution of the ammoniacal liquor prepared above, and vigorously stirred (stirring speed 1200r / min) for 10 minutes, then at a lower speed (stirring speed 600r / min) ) was added to the n-butanol solution of the remaining tetraethyl orthosilicate prepared above to the n-butanol solution of ammonia water prepared above, and kept stirring (stirring rate 1000r / min)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com