Method for preparing nanometer sulfides powder

A powder material, sulfide technology, applied in chemical instruments and methods, lead sulfide, zinc sulfide, etc., can solve the problems of large particle size, wide size range, low purity, etc., achieve narrow particle size distribution, avoid agglomeration, The effect of high powder purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

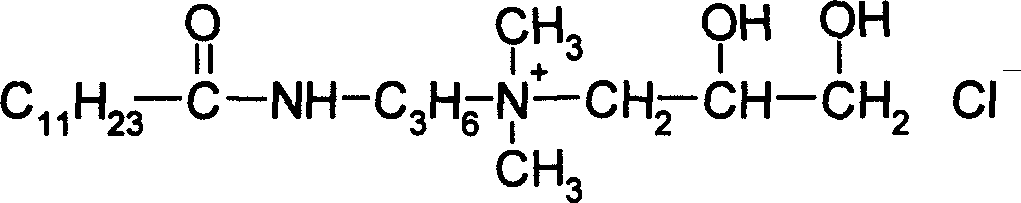

[0015] Example 1: ZnSO 4 13.72g (0.085mol) was formulated to a concentration of 1.0×10 -4 mol / L solution, add 6g (0.6%) quaternary ammonium salt, Na 2 S9.95g was formulated into a solution with a concentration of 1.0×10 -3 mol / L. Na 2 S solution was slowly dropped into ZnSO 4 In the solution, stir rapidly at the same time, continue to stir for a period of time after the addition, then filter, wash with water, dry, and calcined at 750°C. Finally, 6.22 g of white ZnS powder was obtained, with a particle size of 20-120 nm.

Embodiment 2

[0016] Embodiment two: the CdSO 4 18.81g (0.09mol) was formulated to a concentration of 1.2×10 -4 mol / L solution, add 4.57g (0.5%) quaternary ammonium salt, Na 2 S10.53g was formulated into a solution with a concentration of 1.0×10 -3 mol / L. Na 2 S solution was slowly dropped into CdSO 4 In the solution, stir rapidly at the same time, continue to stir for a period of time after the addition, then filter, wash with water, dry, and calcined at 750°C. Finally, 10.40 g of orange CdS powder was obtained, with a particle size of 20-100 nm.

Embodiment 3

[0017] Embodiment three: Pb(NO 3 ) 2 52.99g (0.16mol) was formulated to a concentration of 2.0×10 -4 mol / L solution, add 10.00g (0.9%) quaternary ammonium salt, Na 2 S18.73g was formulated into a solution with a concentration of 1.0×10 -3 mol / L. Na 2 S solution was slowly dropped into Pb(NO 3 ) 2 In the solution, stir rapidly at the same time, continue to stir for a period of time after the addition, then filter, wash with water, dry, and calcined at 750°C. Finally, 34.45 g of blue PbS powder was obtained, with a particle size of 50-140 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com