Biological method for preparing ferrite-bismuth ferrite composite fluorescent material

A fluorescent material, bismuth ferrite technology, applied in the direction of luminescent materials, chemical instruments and methods, fermentation, etc., can solve the problem of low cost, reducing the effective electron and hole velocity of nano-coating body, and easy fluorescence quenching of nanoparticles, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

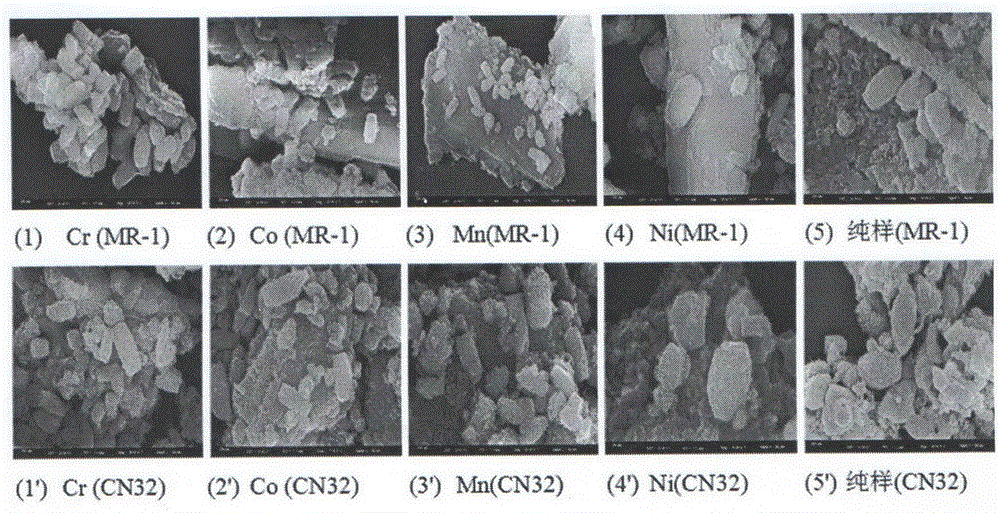

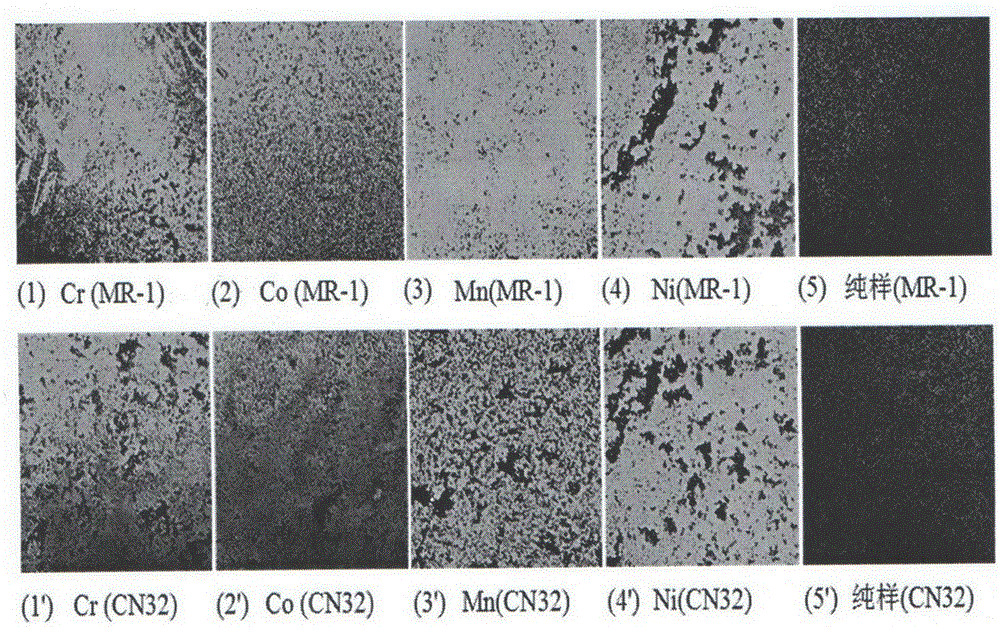

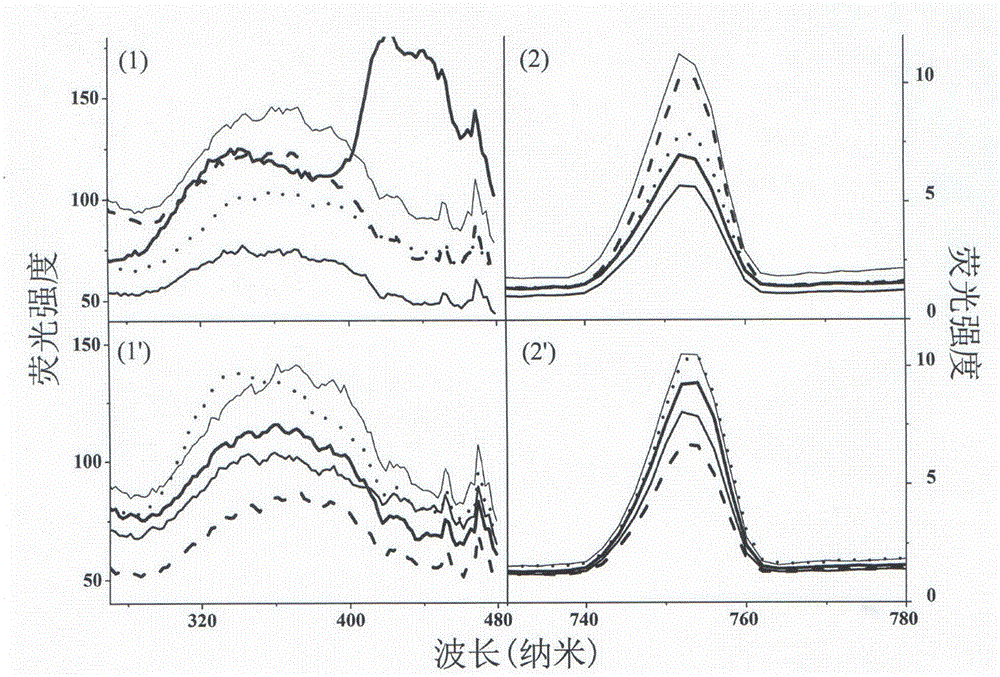

Embodiment 1

[0017] a. In tryptone soybean broth medium tryptone 17g, soybean peptone 3g, sodium chloride 100g, dipotassium hydrogen phosphate 2.5g, glucose 2.5g, distilled water 1000ml, 30g / L Shewanella putrefaciens MR- 1. Cultivate with iron-reducing bacteria CN-32 for 48 hours, and then centrifuge Shewanella putrefaciens MR-1 and iron-reducing bacteria CN-32 under freezing conditions at a temperature of 5°C to obtain the two microorganisms required for the synthesis of fluorescent materials;

[0018] B, take the transition metal ion CrCl as chromium in molar ratio: iron=1:2 2 and FeCl 3 .6H 2 O raw material, put it into the nitric acid aqueous solution with the pH value of 2 at a temperature of 85°C to undergo a peptization reflux reaction, the solution changes from colorless and transparent to a red suspension, and after 2 hours of reaction, let it stand for stratification, centrifuge, and dissolve at a temperature of 50 ℃ vacuum drying for 20 hours to obtain a khaki powder product, ...

Embodiment 2

[0022] a. In tryptone soybean broth medium tryptone 17g, soybean peptone 3g, sodium chloride 100g, dipotassium hydrogen phosphate 2.5g, glucose 2.5g, distilled water 1000ml, 30g / L Shewanella putrefaciens MR- 1. Cultivate with iron-reducing bacteria CN-32 for 48 hours, and then centrifuge Shewanella putrefaciens MR-1 and iron-reducing bacteria CN-32 under freezing conditions at a temperature of 5°C to obtain the two microorganisms required for the synthesis of fluorescent materials;

[0023] B, the molar ratio is cobalt: iron=1:2 takes transition metal ion CoCl 2 (cobalt chloride) and iron ion FeCl 3 .6H 2 The O (ferric chloride hexahydrate) raw material is put into the nitric acid aqueous solution with a pH value of 2 at 85°C to undergo a peptization reflux reaction, and the reactant immediately undergoes a peptization reflux reaction, and the solution changes from colorless and transparent to a yellow suspension solution, after 2 hours of reaction, the mixture was allowed t...

Embodiment 3

[0027] a. In tryptone soybean broth medium tryptone 17g, soybean peptone 3g, sodium chloride 100g, dipotassium hydrogen phosphate 2.5g, glucose 2.5g, distilled water 1000ml, 30g / L Shewanella putrefaciens MR- 1. Cultivate with iron-reducing bacteria CN-32 for 48 hours, and then centrifuge Shewanella putrefaciens MR-1 and iron-reducing bacteria CN-32 under freezing conditions at a temperature of 5°C to obtain the two microorganisms required for the synthesis of fluorescent materials;

[0028] B, by molar ratio is manganese: iron=1:2 takes transition metal ion MnCl 2 (manganese chloride) and iron ion FeCl 3 .6H 2O (ferric chloride hexahydrate) raw material, reflux in an aqueous solution of nitric acid with a pH value of 2 at a temperature of 85°C, and the reactant will undergo a peptization reflux reaction, and the solution will change from colorless and transparent to a green suspension within 2 hours After the reaction is completed, let stand to separate layers, centrifuge, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com