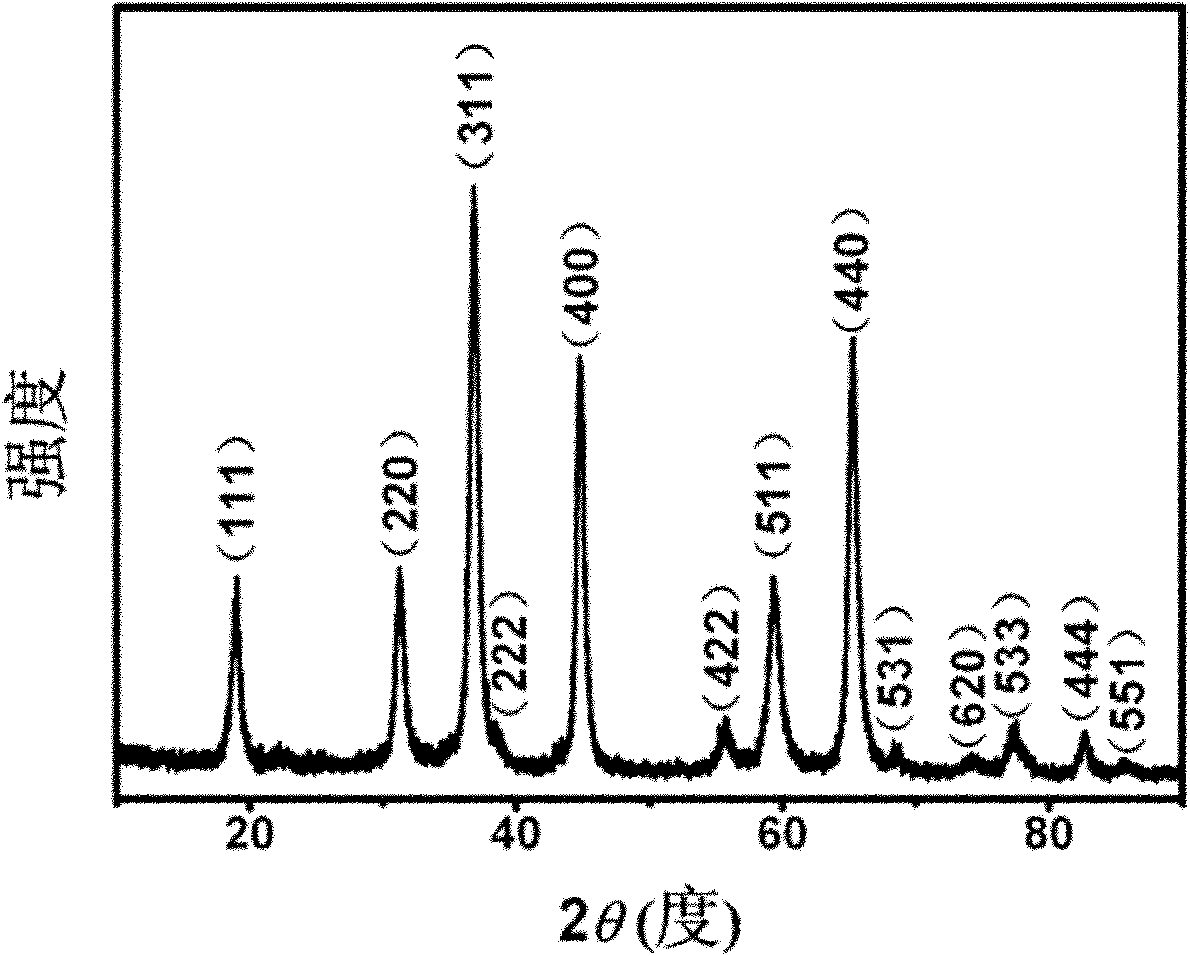

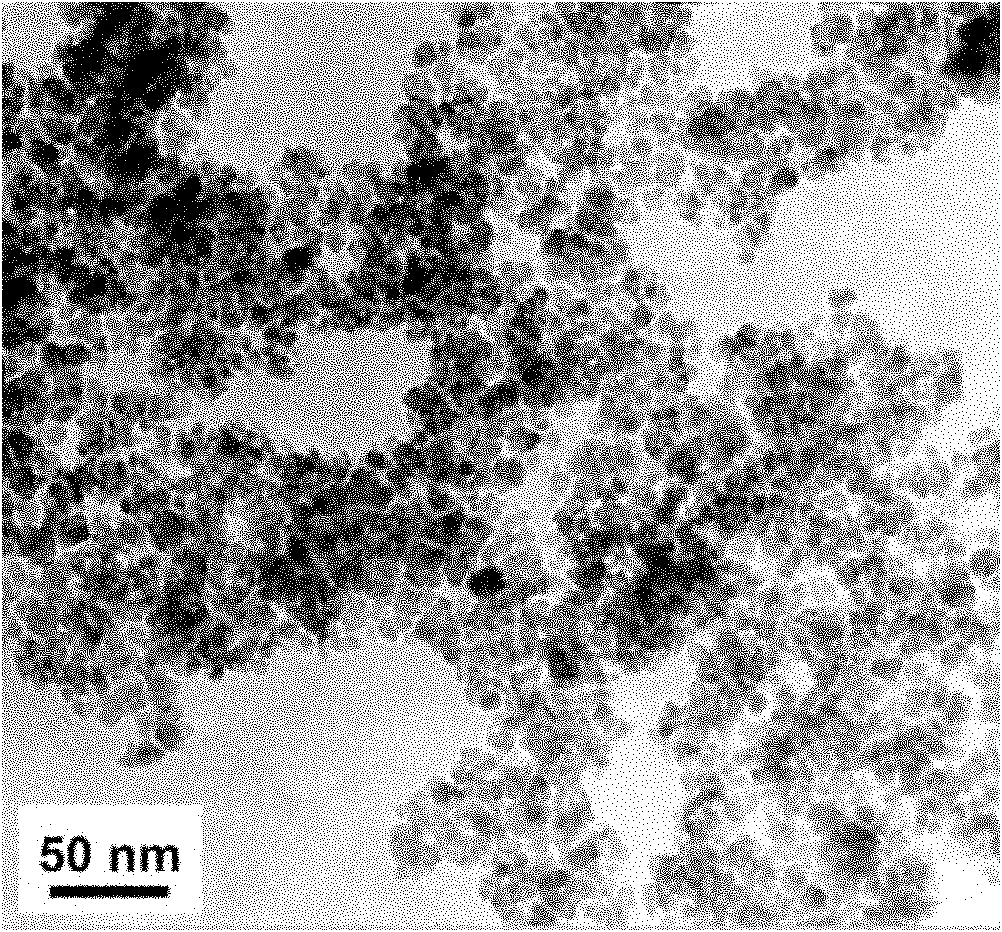

Method for preparing magnesium-aluminum spinel nano particle powder

A magnesium-aluminum spinel and nano-particle technology, which is applied in the direction of alumina/hydroxide, etc., can solve the problems of environmental pollution, high energy consumption, serious agglomeration of magnesium-aluminum spinel nano-particle powder, and achieve particle size Small size, low energy consumption, and the effect of preventing hard agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The method for preparing magnesium-aluminum spinel nanoparticle powder in the present invention is to prepare aluminum soluble inorganic salts into Al 3+ An aqueous solution with a concentration of 0.5mol / L, the aluminum salt used can be AlCl 3 , or Al(NO 3 ) 3 , or Al 2 (SO 4 ) 3 . Then add alkali, such as ammonia water, sodium hydroxide or other alkali, adjust the pH value of the solution to 9, then filter out aluminum hydroxide, wash it, dry it at 80°C and grind it to 500 mesh Fine powder, then add the ground fine powder into the magnesium sulfate solution, wherein the molar ratio of magnesium sulfate to aluminum hydroxide is 10 to 100, after thorough stirring, carry out drying treatment at 80°C to obtain aluminum hydroxide and The mixed powder of magnesium sulfate is then calcined at 800-950°C for 2-5 hours, and the calcined product is washed with water to remove the magnesium sulfate and then dried at 80°C.

[0017] The preferred preparation method of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com