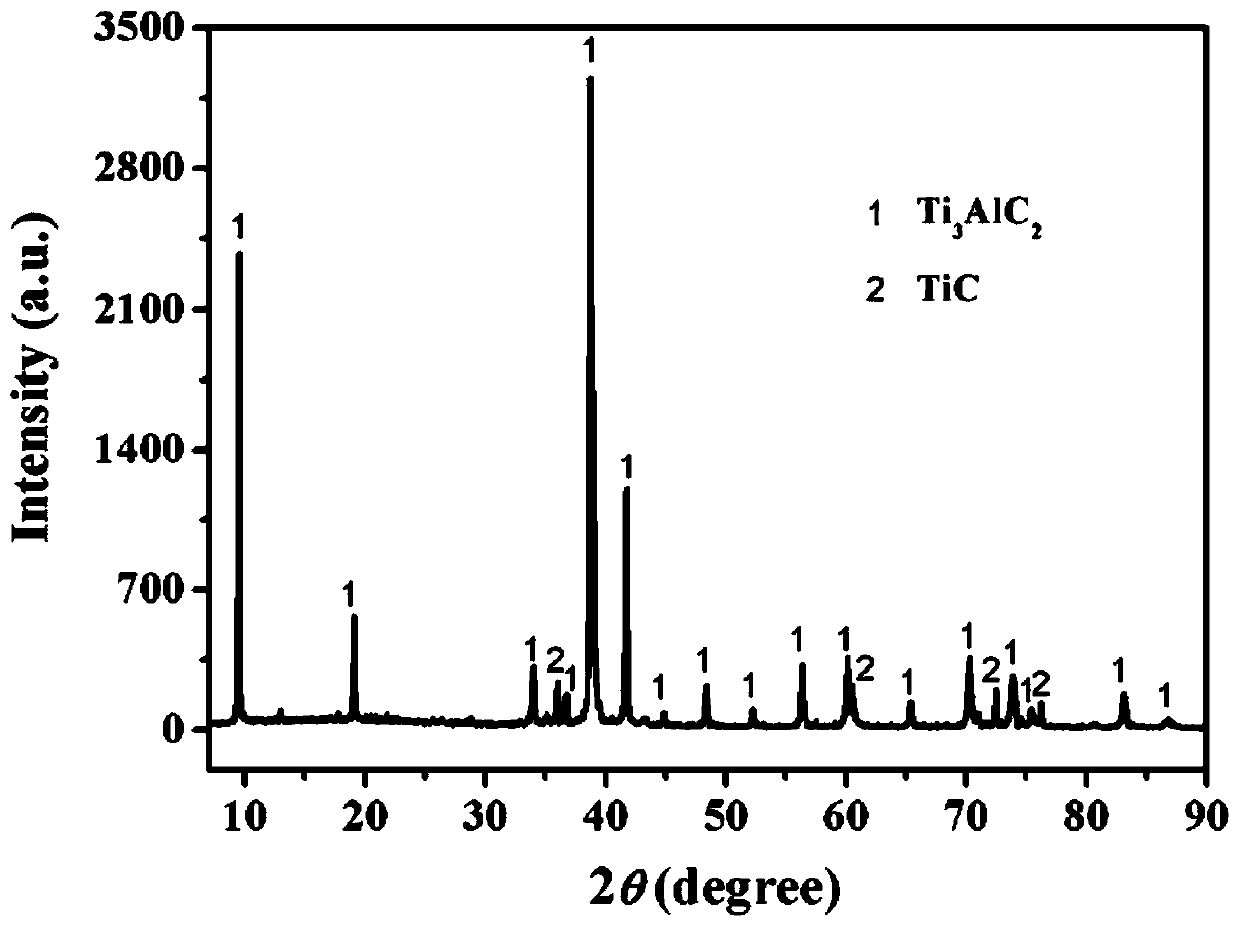

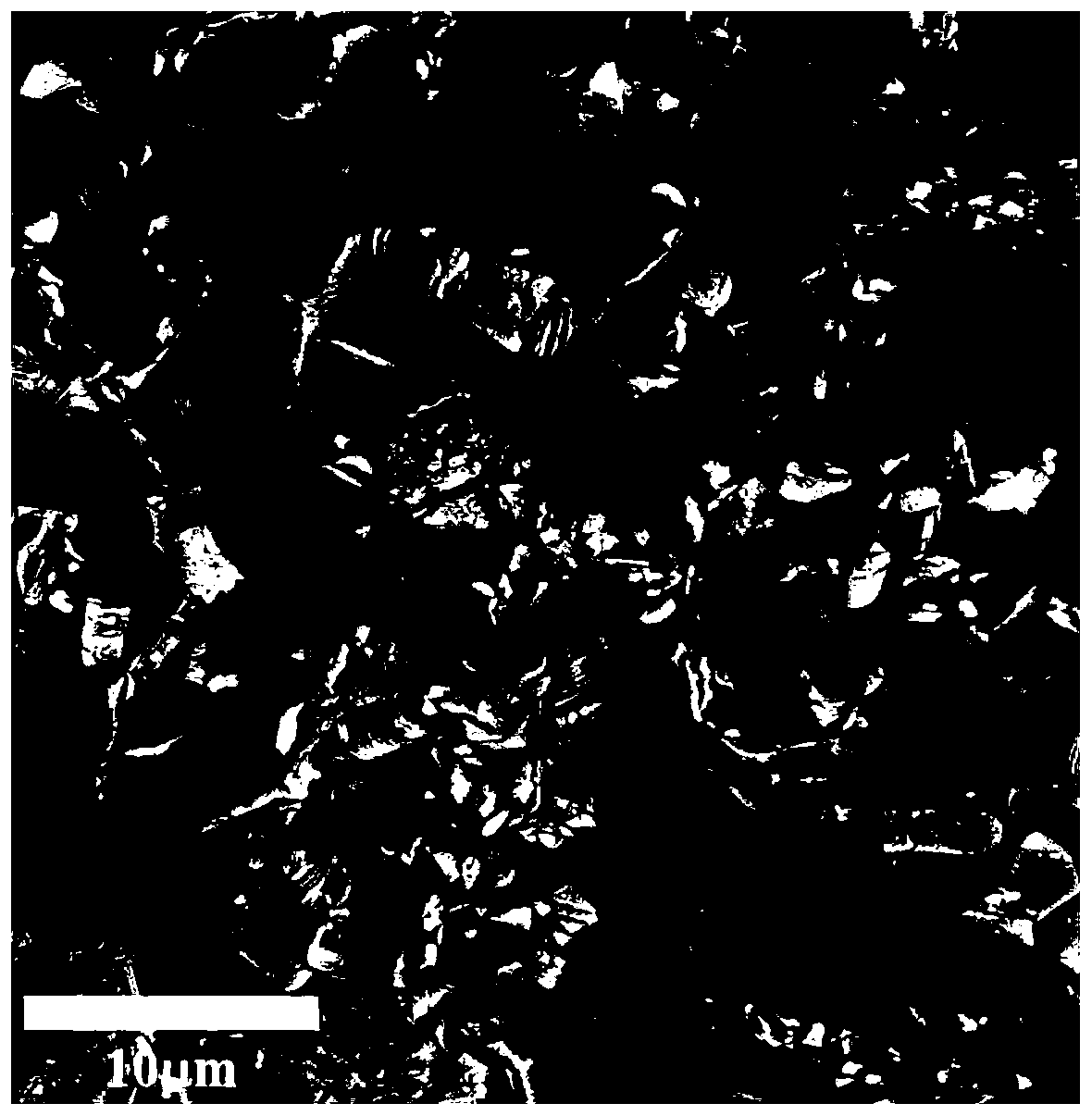

Ti3AlC2 powder and preparation method thereof

A technology of powder and titanium powder, applied in the field of Ti3AlC2 powder and its preparation, can solve the problems of low production efficiency, high synthesis temperature and long cycle, and achieve the effects of high production efficiency, high powder purity and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A Ti 3 AlC 2 Powder and its preparation method. The specific steps of the preparation method described in this embodiment are:

[0044] Step 1. According to the molar ratio of titanium powder: aluminum powder: graphite of 3:1:1, mix the titanium powder, the aluminum powder and the graphite to obtain a reaction material; then press sodium chloride and potassium chloride The molar ratio is 1:1, the sodium chloride and the potassium chloride are mixed to obtain a molten salt medium; then according to the mass ratio of the reaction material: the molten salt medium is 1:2.5, the The reaction material is mixed with the molten salt medium to obtain a mixture material.

[0045] Step 2: Put the mixed material and the agate ball in a planetary ball mill according to the mass ratio of the mixture material: agate ball to 1:2, and ball mill for 1 hour to obtain a ball abrasive.

[0046] Step 3. Put the ball abrasives into the alumina crucible, then put the alumina crucible into the therm...

Embodiment 2

[0051] A Ti 3 AlC 2 Powder and its preparation method. The specific steps of the preparation method described in this embodiment are:

[0052] Step 1. According to the molar ratio of titanium powder: aluminum powder: graphite of 3:1.1:2, the titanium powder, the aluminum powder and the graphite are mixed to obtain the reaction material; and then sodium chloride and potassium chloride The molar ratio is 1:1, the sodium chloride and the potassium chloride are mixed to obtain a molten salt medium; then according to the mass ratio of the reaction material: the molten salt medium is 1:4, the The reaction material is mixed with the molten salt medium to obtain a mixture material.

[0053] Step 2: Put the mixed material and the agate ball in a planetary ball mill according to the mass ratio of the mixed material: agate ball to 1:7, and ball mill for 1 hour to obtain a ball abrasive.

[0054] Step 3. Put the ball abrasives into the alumina crucible, then put the alumina crucible into the t...

Embodiment 3

[0059] A Ti 3 AlC 2 Powder and its preparation method. The specific steps of the preparation method described in this embodiment are:

[0060] Step 1. According to the molar ratio of titanium powder: aluminum powder: graphite of 3:1.2:1.8, the titanium powder, the aluminum powder and the graphite are mixed to obtain the reaction material; and then sodium chloride and potassium chloride The molar ratio is 1:1, the sodium chloride and the potassium chloride are mixed to obtain a molten salt medium; then according to the mass ratio of the reaction material: the molten salt medium is 1:1.8, the The reaction material is mixed with the molten salt medium to obtain a mixture material.

[0061] Step 2: Put the mixed material and the agate ball in a planetary ball mill according to the mass ratio of the mixed material: agate ball of 1:6, and ball mill for 1.5 hours to obtain a ball abrasive.

[0062] Step 3. Put the ball abrasives into the alumina crucible, then put the alumina crucible int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com