Silicon nitride powder based on catalytic nitridation and preparation method thereof

A technology of silicon nitride powder and silicon powder, which is applied in the field of silicon nitride powder based on catalytic nitriding and its preparation, can solve the problem of restricting the application and industrial production of silicon nitride powder, and the powder is not in the form of whiskers , complex process and other issues, to achieve the effect of easy control, high production cost, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

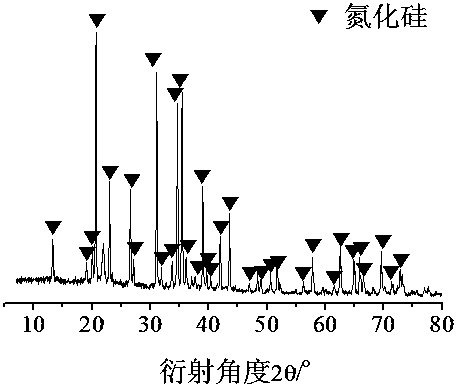

Image

Examples

Embodiment 1

[0032] A silicon nitride powder based on catalytic nitriding and a preparation method thereof. The steps of the preparation method are:

[0033] Step 1. According to the mass ratio of polyvinyl alcohol: silicon powder: distilled water is 1: 200: (10000 ~ 12000), mix polyvinyl alcohol, silicon powder and distilled water, stir for 20 ~ 30 minutes, and then ultrasonically disperse for 20 ~ 30 minutes to prepare to obtain a suspension.

[0034] Step 2, adding concentration to the suspension is the chromium nitrate of 0.88mol / L, makes mixed solution; Wherein, the addition of chromium nitrate is Si: Cr 2 o 3 The mass ratio of is 1: (0.005~0.020).

[0035] Step 3: Add urea to the mixed liquid under stirring condition until the pH value is 7.5-8.5, continue stirring for 0.5-1 h; filter with suction, and dry in vacuum for 10-12 h to obtain a mixed powder.

[0036] Step 4: Put the mixed powder in a tube-type atmosphere furnace, raise the temperature to 1250-1300°C under the conditio...

Embodiment 2

[0038] A silicon nitride powder based on catalytic nitriding and a preparation method thereof. The steps of the preparation method are:

[0039] Step 1. According to the mass ratio of sodium dodecylbenzenesulfonate: silicon powder: distilled water is 1: 200: (14000~16000), mix sodium dodecylbenzenesulfonate, silicon powder and distilled water, and stir for 20~ 30min, and then ultrasonically dispersed for 20~30min to obtain a suspension.

[0040] Step 2, adding concentration to the suspension is chromium chloride of 0.88mol / L to obtain a mixed liquor; wherein, the addition of chromium chloride is Si:Cr 2 o 3 The mass ratio of is 1: (0.025~0.040).

[0041] Step 3: Add ammonia water to the mixed liquid under stirring condition until the pH value is 7.5-8.5, continue stirring for 0.5-1 h; filter with suction, and dry in vacuum for 10-12 h to obtain a mixed powder.

[0042] Step 4: Put the mixed powder in a tube-type atmosphere furnace, raise the temperature to 1350-1400°C unde...

Embodiment 3

[0044] A silicon nitride powder based on catalytic nitriding and a preparation method thereof. The steps of the preparation method are:

[0045] Step 1. According to the mass ratio of polyvinyl alcohol: silicon powder: distilled water is 1: 200: (10000 ~ 12000), mix polyvinyl alcohol, silicon powder and distilled water, stir for 20 ~ 30 minutes, and then ultrasonically disperse for 20 ~ 30 minutes to prepare to obtain a suspension.

[0046] Step 2, adding concentration to the suspension is chromium chloride of 0.88mol / L to obtain a mixed liquor; wherein, the addition of chromium chloride is Si:Cr 2 o 3 The mass ratio of is 1: (0.010~0.025).

[0047] Step 3: Add hydrazine hydrate to the mixed liquid under stirring conditions until the pH value is 7.5-8.5, and continue stirring for 0.5-1 h; filter with suction and dry in vacuum for 10-12 h to obtain a mixed powder.

[0048] Step 4: Put the mixed powder in a tubular atmosphere furnace, raise the temperature to 1300~1350°C under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com