Atmospheric synthesizing method for silicon carbide titanium ceramic powder

A technology of ceramic powder and normal pressure synthesis, which is applied in the normal pressure synthesis of silicon carbide titanium ceramic powder, low-cost high-purity silicon carbide titanium Ti3SiC2 ceramic powder in the field of normal pressure synthesis, to reduce synthesis cost and simple process flow , temperature parameters are stable and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

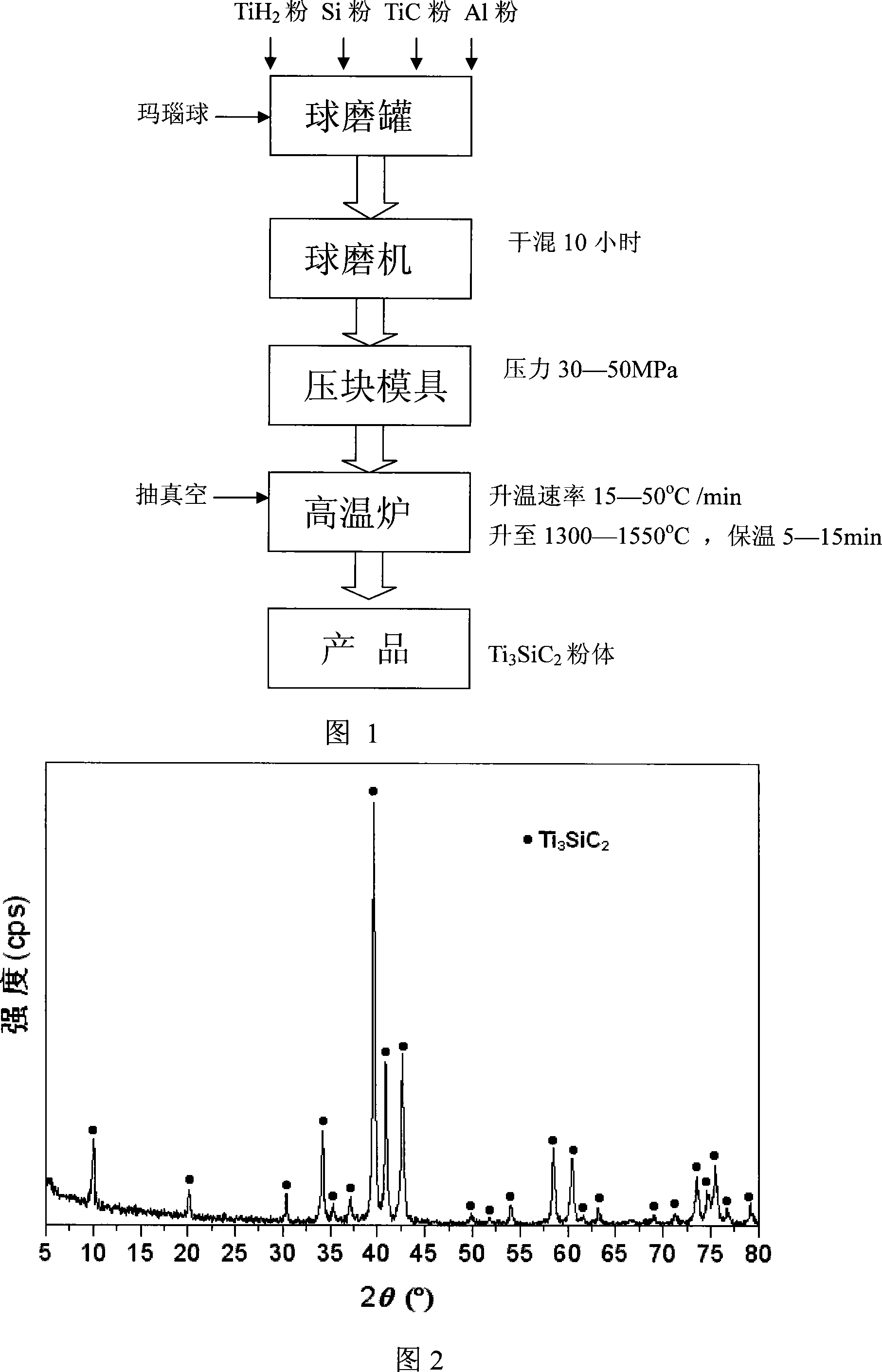

[0021] Embodiment 1: A normal pressure synthesis method of silicon carbide titanium ceramic powder: contains the following steps;

[0022] 1) Press TiH 2 :Si:TiC:Al=1:1:1.8:0.2 molar ratio ingredients, weigh TiH 2 26.10 grams of Si powder, 14.69 grams of Si powder, 56.38 grams of TiC powder, and 2.82 grams of Al powder;

[0023] 2) Put the above-mentioned ingredients into the ball mill tank and place on the ball mill for mixing for 10 hours;

[0024] 3) Place the uniformly mixed ingredients in a briquetting mold and press them into a block under a pressure of 30MPa;

[0025] 4) Put the above-mentioned briquettes into a high-temperature furnace, and raise the temperature of the furnace to 1300° C. at a heating rate of 15° C. / min under a vacuum atmosphere, and the holding time is 10 minutes. Ti 3 SiC 2 powder, the X-ray diffraction (XRD) spectrum of the powder is shown in Figure 2. It can be seen from Figure 2 that the product has high purity, only Ti 3 SiC 2 Phase diffr...

Embodiment 2

[0026] Embodiment 2: A normal-pressure synthesis method of silicon carbide titanium ceramic powder: contains the following steps;

[0027] 1) Press TiH 2 :Si:TiC:Al=1:1:1.9:0.2 molar ratio ingredients, weigh TiH 2 25.29 grams of Si powder, 14.25 grams of Si powder, 57.72 grams of TiC powder, and 2.74 grams of Al powder;

[0028] 2) Put the above-mentioned ingredients into the ball mill tank and place on the ball mill for mixing for 10 hours;

[0029] 3) Place the uniformly mixed ingredients in a briquetting mold and press them into a block under a pressure of 40 MPa;

[0030] 4) Put the above-mentioned briquettes into a high-temperature furnace, and raise the temperature of the furnace to 1450° C. at a heating rate of 30° C. / main under a vacuum atmosphere, and the holding time is 15 minutes. Ti 3 SiC 2 Powder, its XRD result is identical with embodiment 1.

Embodiment 3

[0031] Embodiment 3: A normal-pressure synthesis method of silicon carbide titanium ceramic powder: contains the following steps;

[0032] 1) Press TiH 2 :Si:TiC:Al=1:1:2:0.2 molar ratio ingredients, weigh TiH 2 24.54 grams of Si powder, 13.83 grams of Si powder, 58.96 grams of TiC powder, and 2.66 grams of Al powder;

[0033] 2) Put the above-mentioned ingredients into the ball mill tank and place on the ball mill for mixing for 10 hours;

[0034] 3) Place the uniformly mixed ingredients in a briquetting mold and press them into a block under a pressure of 50MPa;

[0035] 4) Put the above-mentioned briquettes into a high-temperature furnace, and raise the temperature of the furnace to 1550° C. at a heating rate of 40° C. / min under a vacuum atmosphere, and the holding time is 5 minutes. Ti 3 SiC 2 Powder, its XRD result is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com